Wheel type omnidirectional claw wall-climbing robot and moving method thereof

A wall-climbing robot and claw technology, applied in the direction of motor vehicles, wheels, transportation and packaging, etc., can solve the problems of inability to move horizontally, and achieve the effect of fast crawling speed, convenient control and increased gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Describe in detail with reference to the accompanying drawings

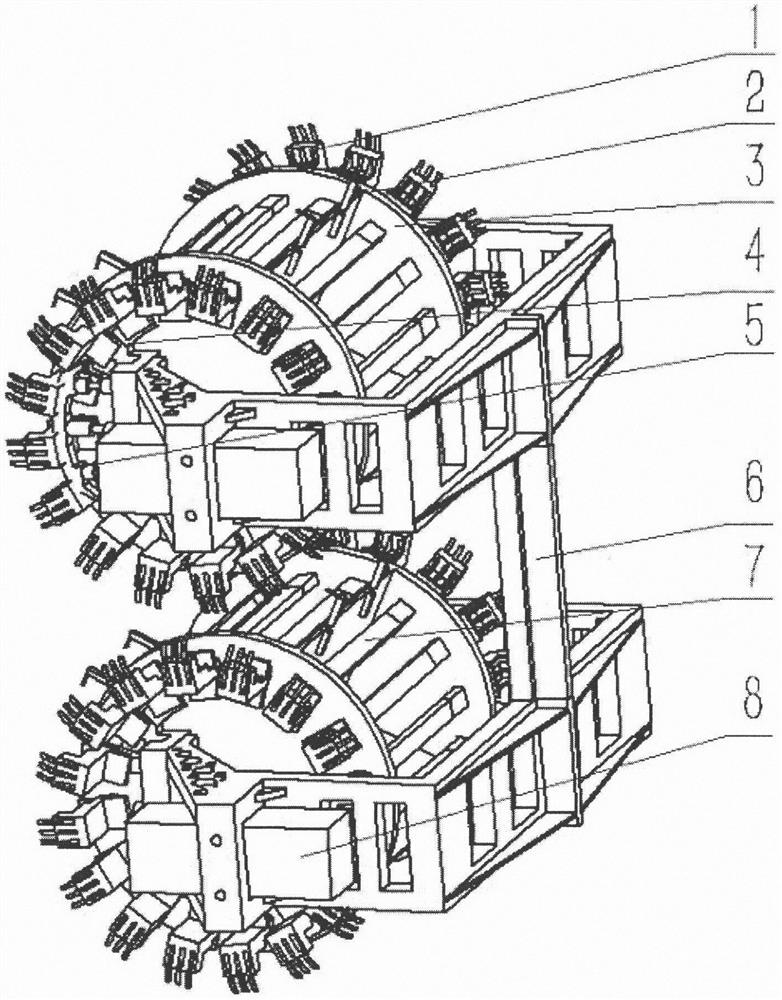

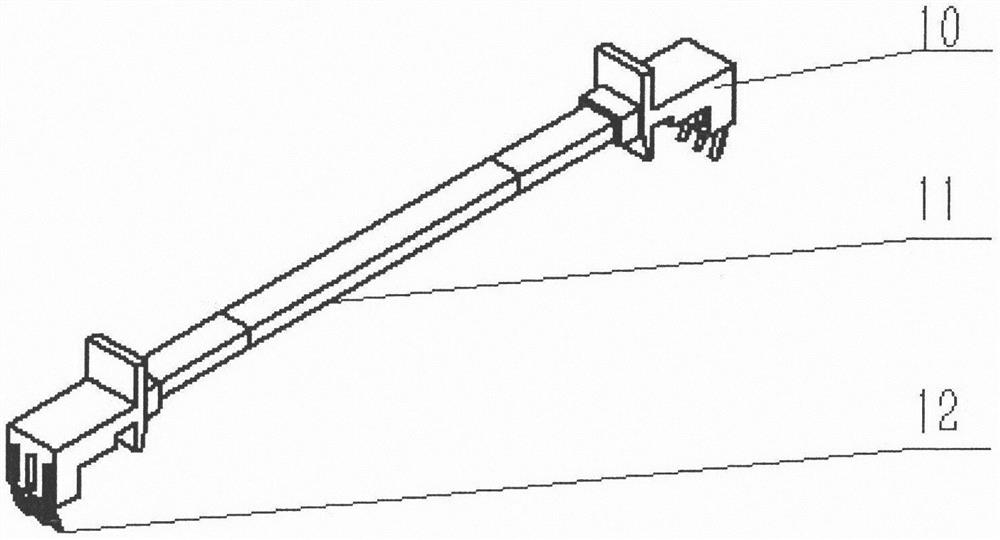

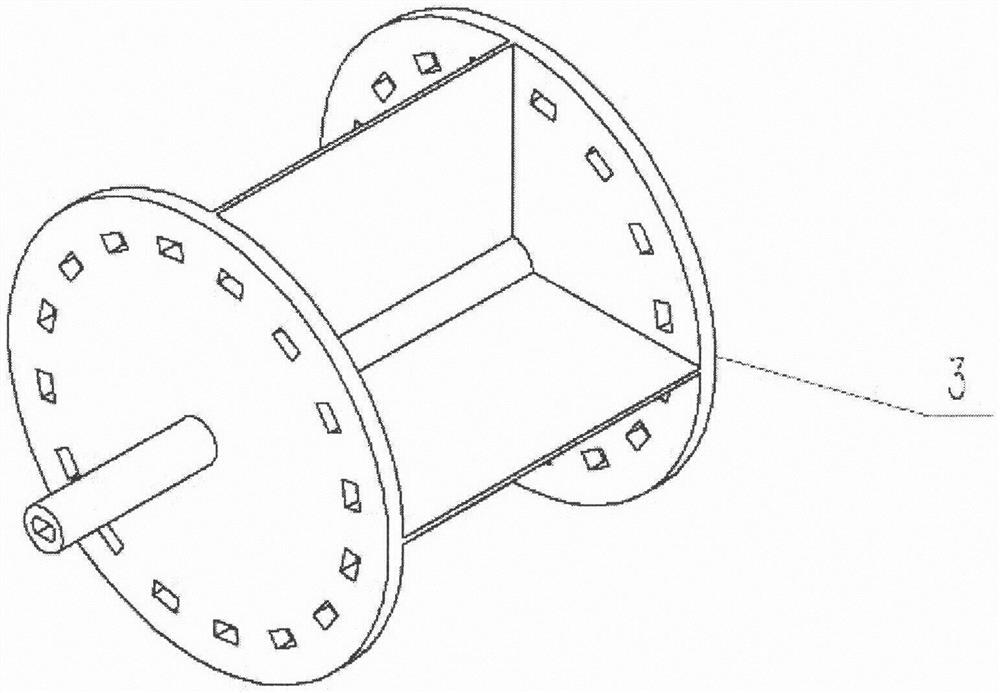

[0017] combine figure 1 and Figure 7 , the wheeled omnidirectional hook wall-climbing robot consists of two omnidirectional wheeled hook modules installed on the frame. The composition of the robot includes a frame 6, a DC motor 8 and a boss base 4 are installed on the frame. An extruding rod 5 is installed at the bottom of the boss base, and the runner 3 is installed on the output shaft of the DC motor. At least two longitudinal soft hooks 2 are arranged on the runner support plate. The number of soft hooks can be adjusted according to the Select the appropriate number of support plates in the middle, and there are 16 pairs of horizontal hooks 1 installed on both sides of the runner. The number of horizontal hooks can be selected according to the needs of the radius of the runner. figure 2 The composition of the horizontal claws includes a metal sharp hook 12 installed on the top of the horizontal cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com