Gap adjusting device for printing roller sets of carton printing machine

A gap adjustment device and printing roller technology, which is applied in printing machines, rotary printing machines, printing, etc., can solve the problems of inconvenient printing of cartons with different thicknesses, different thicknesses of cartons, and the inability to adjust the gap of the brush roller group, achieving a scientific structure Reasonable, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

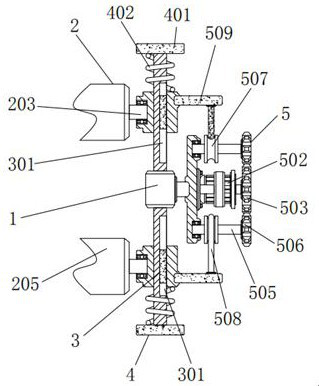

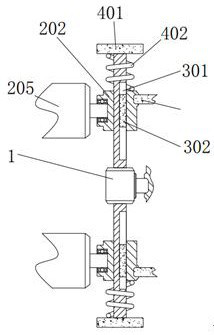

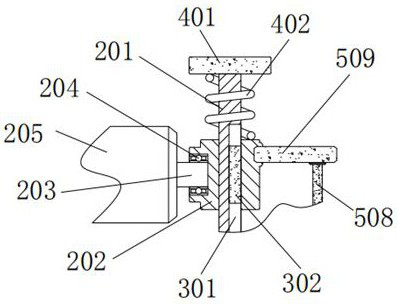

[0035] A gap adjustment device for a printing roller group of a carton printing machine, comprising a sleeve 1, the top and bottom of the sleeve 1 are provided with a printing roller mechanism 2, and the printing roller mechanism 2 includes a sliding rod 201, a sliding sleeve 202, and a first bearing 203 , the rod body 204 and the printing roller 205, the sliding rod 201 is adjusted on the inner wall of the sleeve 1, and the upper and lower outer walls of the sliding rod 201 are slidably connected with a sliding sleeve 202, so that the sliding sleeve 202 can lift and slide on the outer wall of the sliding rod 201, The left sides of the two sliding sleeves 202 are connected to the rod body 204 through the rotation of the first bearing 203, and the outer walls of the two rod bodies 204 are fixedly connected with the printing roller 205, so that the rod body 204 can drive the printing roller 205 to rotate on the outer wall of the sliding sleeve 202, The midpoints of the sliding ro...

Embodiment 2

[0037] As an option, see Figure 1-4 , the gap adjustment device of the printing roller group of the carton printing machine, the auxiliary mechanism 3 is provided above and below the right side of the outer wall of the slide bar 201. Above and below the right side of the outer wall of the rod 201, the inner walls of the two chute 301 are slidably connected with a slider 302, so that when the sliding sleeve 202 moves up and down, it can be connected by the sliding of the slider 302 in the chute 301 for stable movement. Lifting and sliding, the right side of the slider 302 and the right side of the inner wall of the sliding sleeve 202 are fixed together, the sliding block 302 and the chute 301 form a sliding limit structure, so that the sliding sleeve 202 can be stably lifted on the outer wall of the sliding rod 201 sports.

[0038] The solution in this embodiment can be selectively used in combination with the solutions in other embodiments.

Embodiment 3

[0040] As an option, see Figure 1-4 , the gap adjustment device of the printing roller group of the carton printing machine, the top and bottom of the slide bar 201 are provided with a reset mechanism 4, the reset mechanism 4 includes a plate body 401 and a spring 402, and the two plate bodies 401 are respectively fixed on the bottom of the slide bar 201 At the top and bottom, two springs 402 are respectively spaced above and below the outer wall of the slide bar 201. The outer side of the spring 402 is fixed to the outer wall of the plate body 401, and the inner side of the spring 402 is fixed to the outer wall of the sliding sleeve 202. The spring 402 gives The sliding sleeve 202 pulls the reset force on the outer wall of the sliding rod 201 .

[0041] The solution in this embodiment can be selectively used in combination with the solutions in other embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com