Steel structure clamp

A steel structure and fixture technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of difficult to meet the installation work of multiple beams, waste of materials, and prolong the installation period, so as to achieve convenient installation, enhanced reliability, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

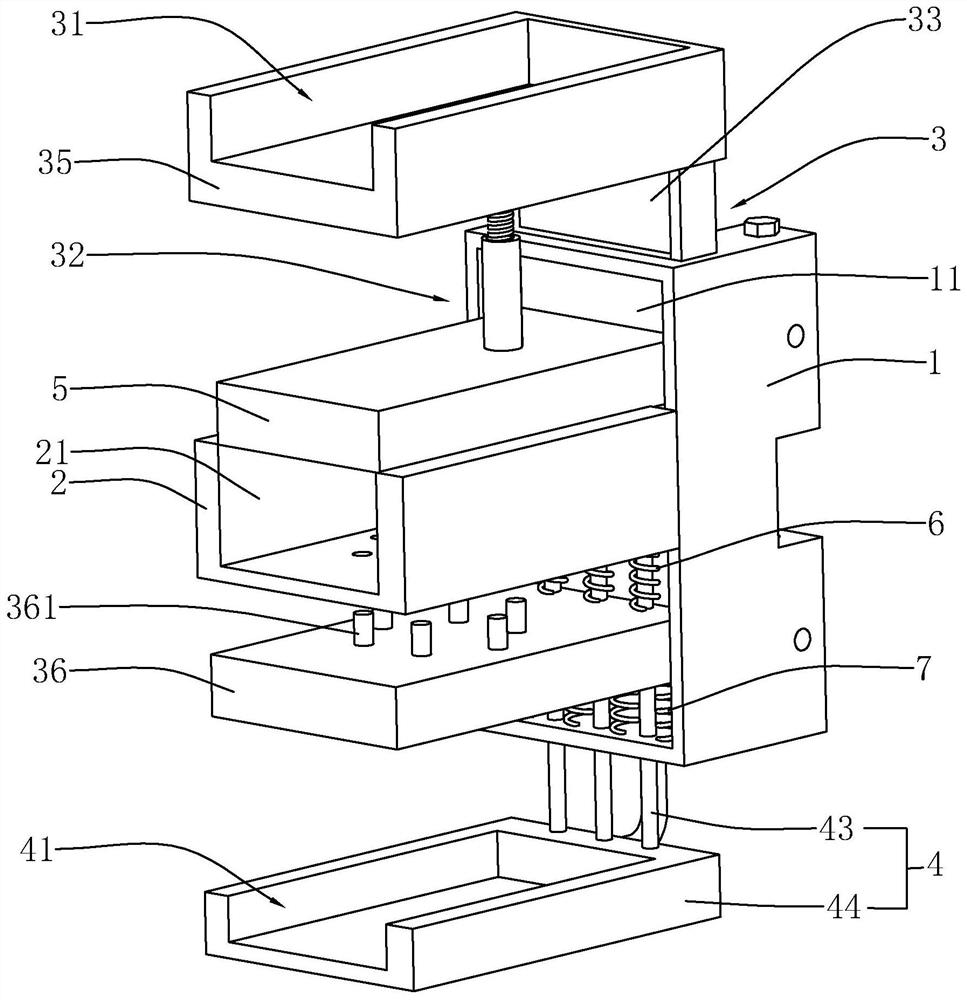

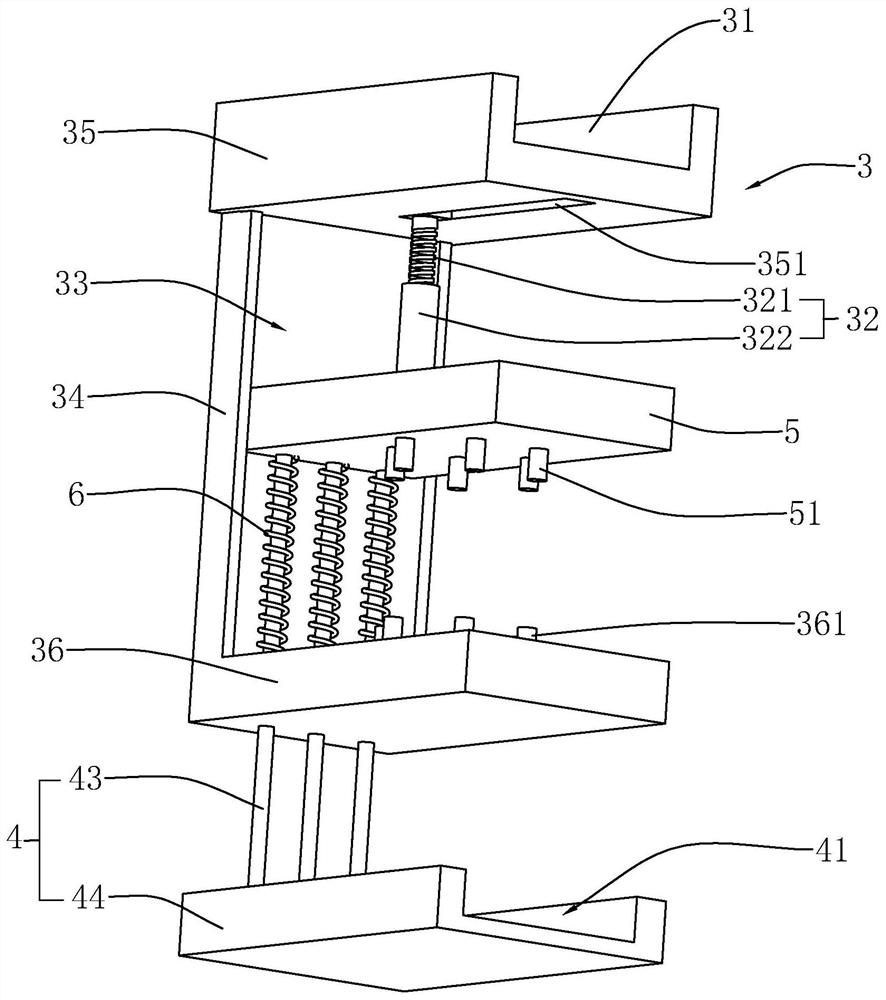

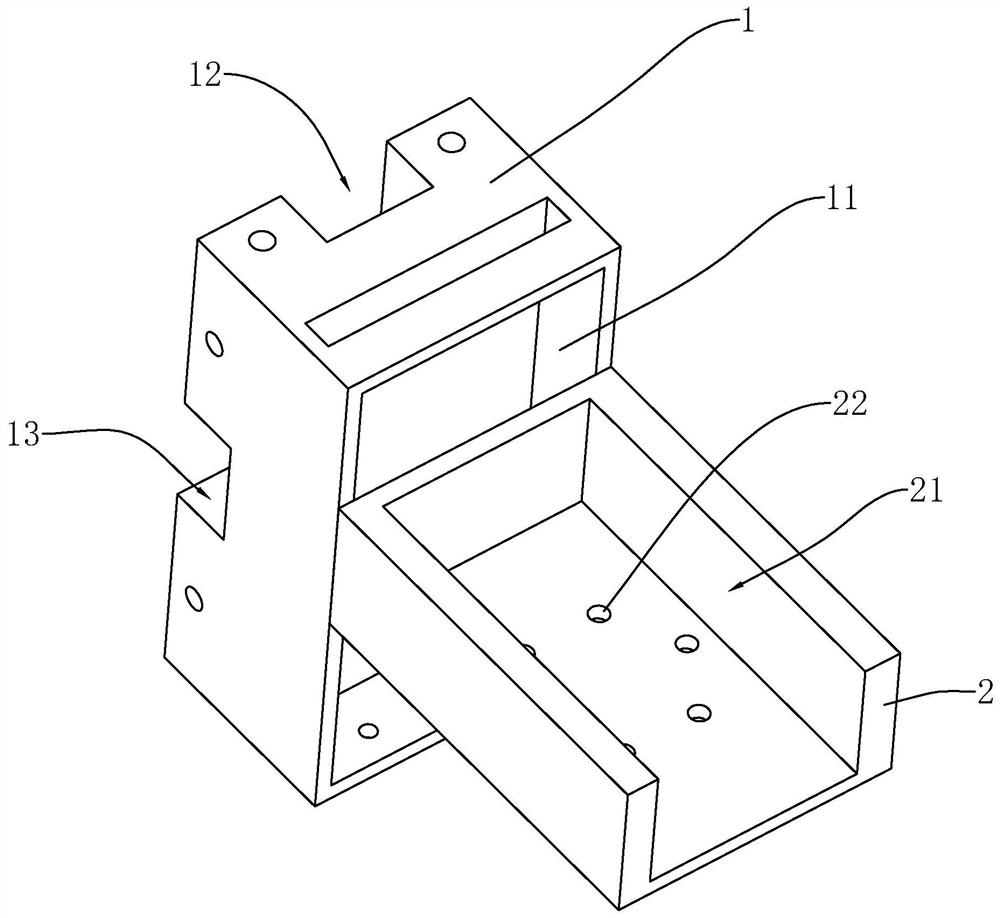

[0034] refer to figure 1 , is a steel structure fixture disclosed in the present invention, comprising a rectangular mounting base 1, a first bracket 2 placed horizontally is fixedly mounted on a vertical surface of the mounting base 1, and the upper end surface of the first bracket 2 is provided with The first clamping groove 21 with the opening facing upwards. The mounting base 1 is provided with a sliding slot 11 opening toward the first bracket 2 , and the second bracket 3 and the third bracket 4 are slidingly arranged in the sliding slot 11 along the vertical direction.

[0035] Such as figure 1 , figure 2 As shown, the second bracket 3 includes a main board 34 slidably arranged in the chute 11 , an upper cover 35 fixedly installed on the top of the main board 34 and a lower cover 36 fixedly installed on the bottom of the main board 34 . The upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com