Coating device and coating machine

A technology of coating device and coating roller, which is applied in the field of coating, can solve the problems of poor coating accuracy, fixed position, and inability to fine-tune the distance, and achieve high coating accuracy, ensure stability and reliability, and facilitate adjustment and control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

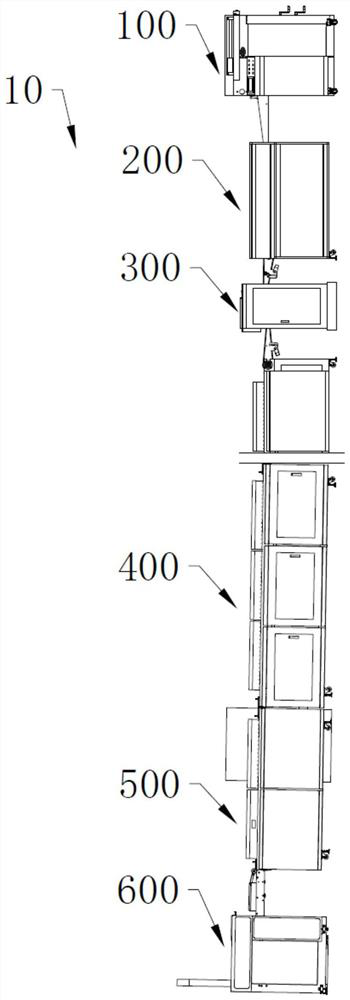

[0037] Such as Figure 1 to Figure 7 As shown, a coating machine 10 includes a feeding device 100 , a powder removing device 200 , a coating device 300 , several sets of drying devices 400 , a cooling device 500 and a receiving device 600 arranged in sequence. Also features quick wheel drive for fast product transport.

[0038] see figure 1 , the coating machine 10 with the above structure is used to collect the product after feeding, powder removal, coating, drying and cooling in order to realize automatic coating.

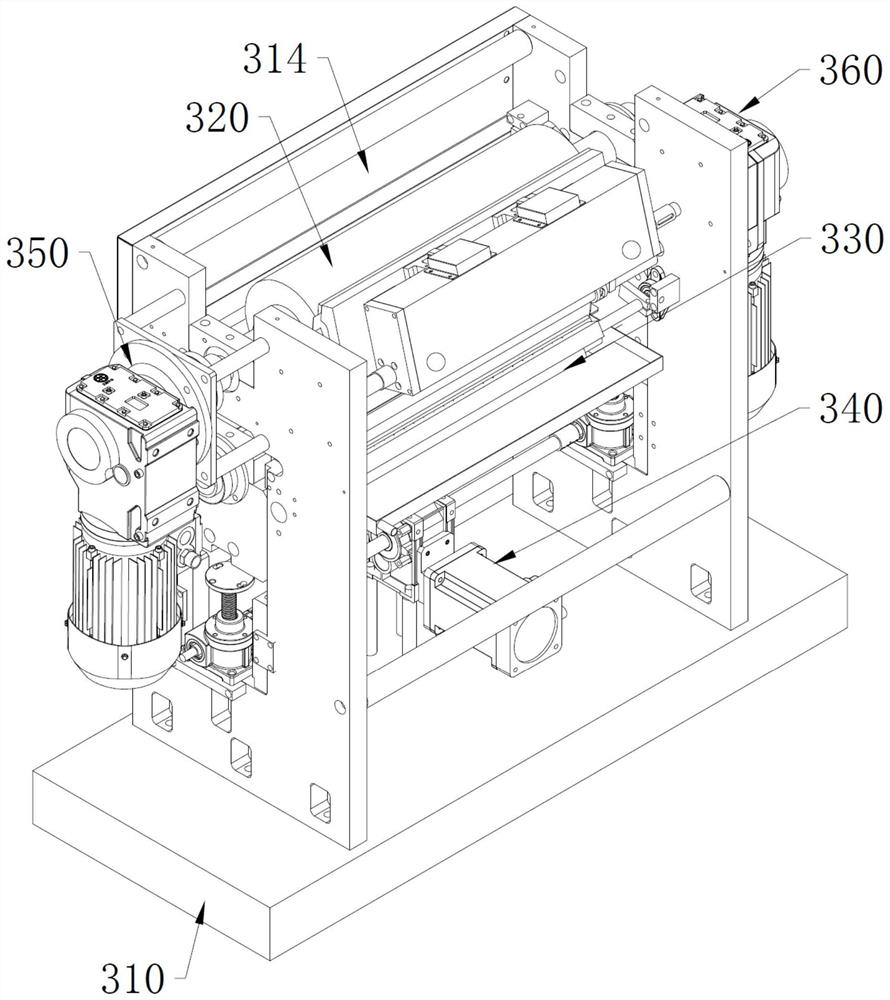

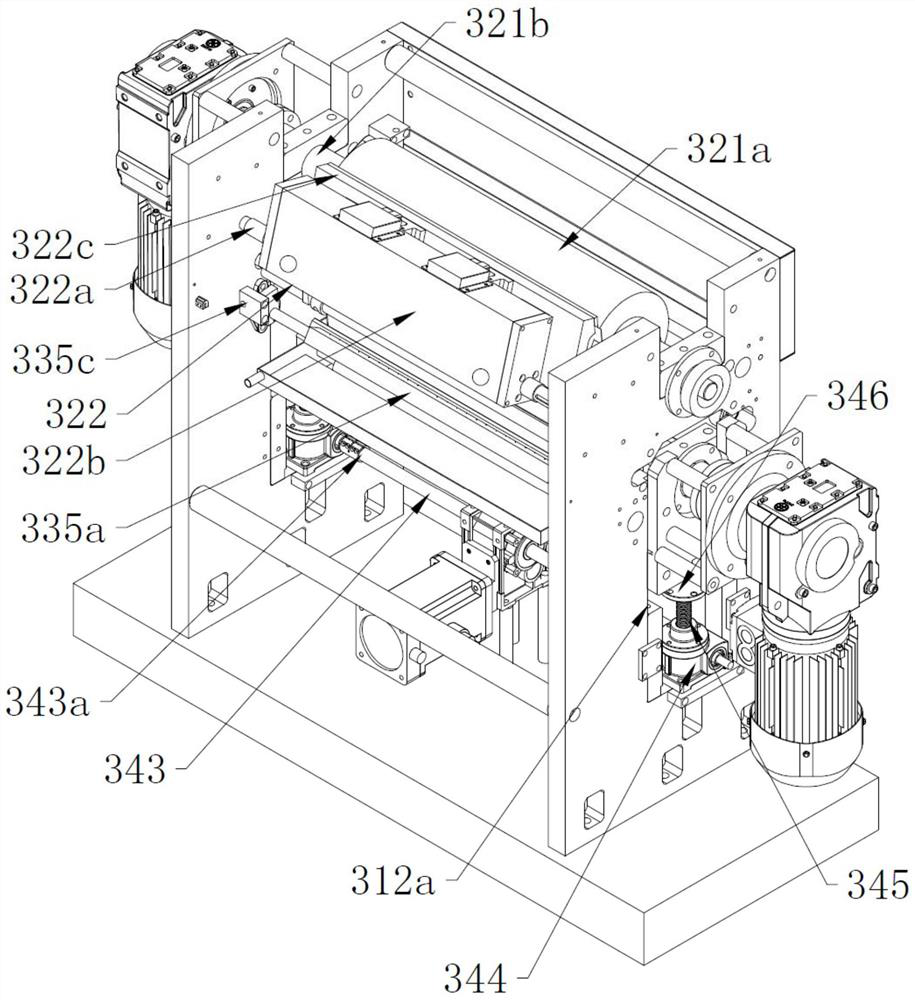

[0039] see image 3 , a coating device 300, comprising a frame 310, a coating roller assembly 320 mounted on the frame 310, a rubber roller assembly 330 mounted on the frame 310 and positioned below the coating roller assembly 320, mounted on the frame 310 for The adjustment assembly 340 that adjusts the rubber roller assembly 330 to lift, the first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com