Slide fastener and method for manufacturing slide fastener

A manufacturing method and zipper technology, which are applied in the directions of sliding fastener elements, applications, fasteners, etc., can solve the problems of large film materials, many films, and hardening, and achieve the effects of reducing dosage, improving operating feel and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

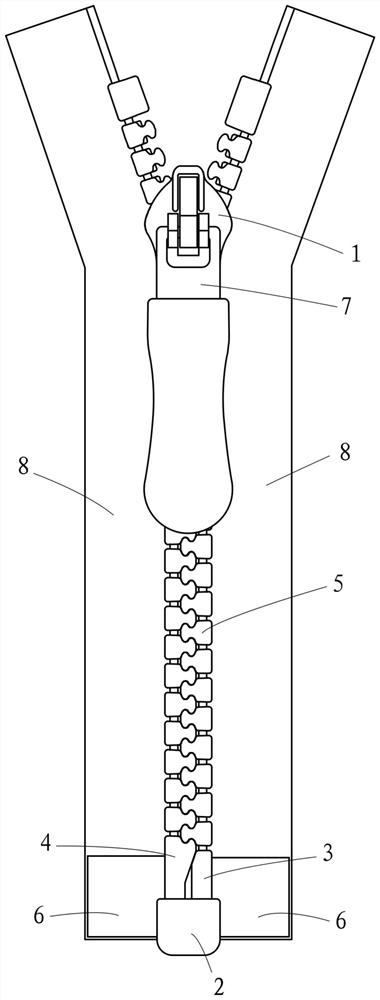

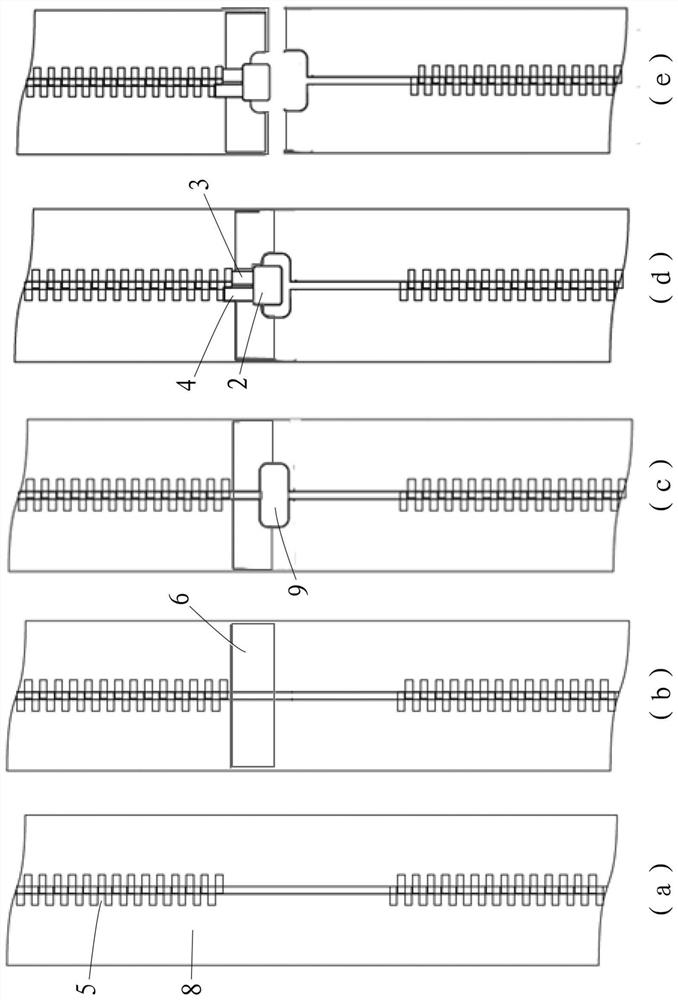

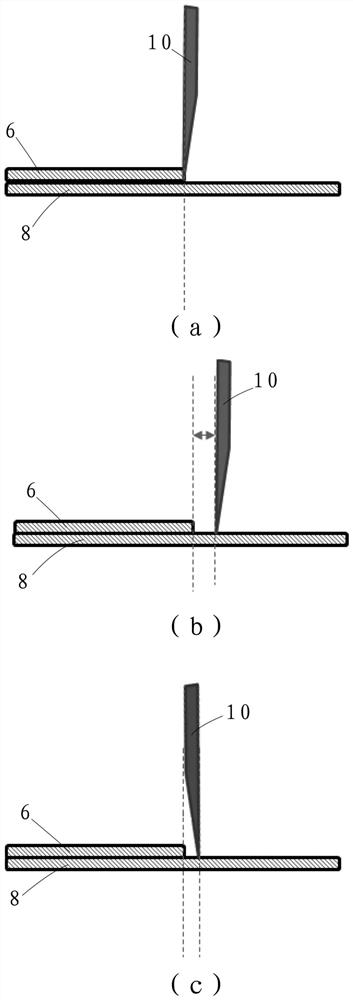

[0052] refer to figure 1 - Figure 4 The slide fastener and the manufacturing method of the slide fastener concerning embodiment of this invention are demonstrated. It should be noted that the drawings are schematic diagrams, and it should be noted that ratios of dimensions and the like are different from actual ones. Therefore, specific dimensions and the like should be determined in consideration of the following description. In addition, the relationship and the ratio of the mutual dimension may differ between drawings.

[0053]In addition, in the description of the present invention, terms defined as follows may be referred to. The front-rear direction is the direction consistent with the length direction of the zipper or the zipper string, and / or the moving direction of the slider, wherein the moving direction when the zipper is closed is forward, and the moving direction when the zipper is opened is backward. The left-right direction is a direction coincident with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com