Automatic stringing machine for flaky food

An automatic threading and food technology, which is applied in the field of automatic threading and stringing machines, can solve the problem of low quality of finished products, and achieve the effects of fixed state of ingredients, excellent quality of skewered products, and unreliable state of ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

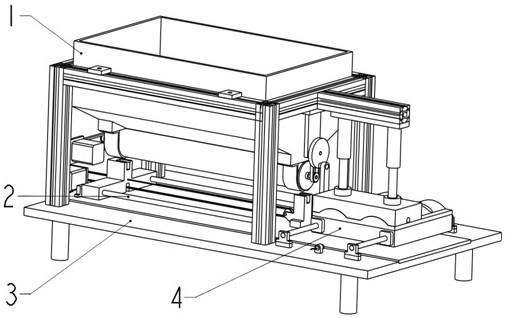

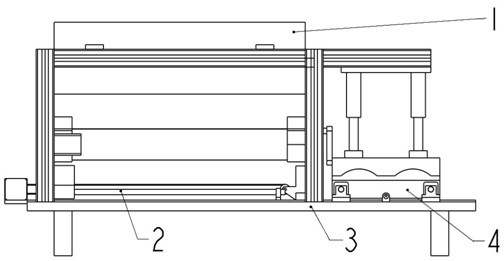

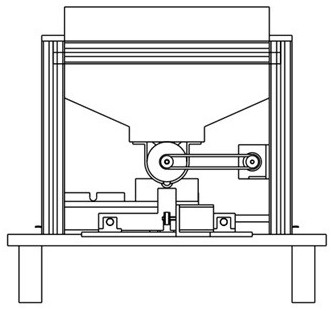

[0034] Embodiment, a kind of automatic threading machine of sheet food, as Figure 1-10 As shown, it includes: a sign-out device 1, a sign-pushing device 2, a base 3, a transposition device 4 and a control device; Installed on the other side above the base 3, the sign-out device 1 is installed above the sign-pushing device 2 and the transposition device 4, and the control device is installed on the side of the base;

[0035]The signing device 1 includes: a storage sign box 101, a profile frame 102, a pressing mechanism 103, a pressing and driving synchronous belt 104, a signing rotating cylinder 105, a rotating cylinder mounting frame 106, a rotating cylinder driving motor 107, a driving motor mounting frame 108, a rotating cylinder Drive synchronous belt 109, synchronous belt pulley 110, there is the opening groove that can fall into bamboo stick on the pick rotating cylinder 105; Press mechanism 103 comprises turntable seat 1031, drive turntable 1032, turntable timing belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com