Rear-stage pump control system and control method for vacuum system

A technology of a vacuum system and a control method, applied in the field of vacuum systems, can solve problems such as unfavorable integration, large equipment footprint, and need for additional power supply, so as to ensure service life and work stability, reduce equipment footprint, and reduce circuits. The effect of layout difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

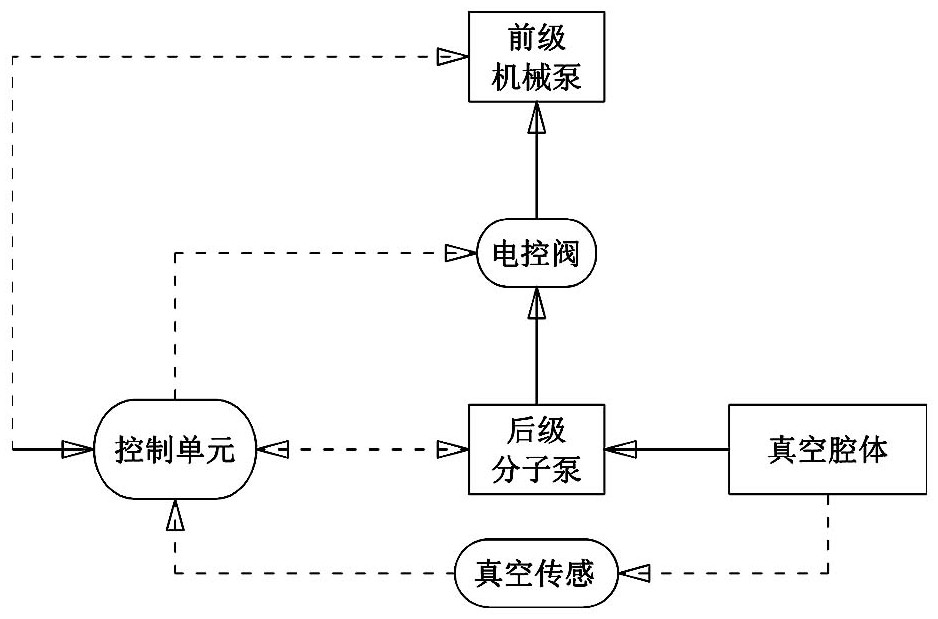

[0050] Such as figure 1 As shown, according to a specific embodiment of the present invention, a back-stage molecular pump control system for a vacuum system is provided, including a vacuum chamber, a back-stage molecular pump, a back-stage mechanical pump, an electric control valve, a vacuum sensor and a control system. unit.

[0051] The suction port of the rear-stage molecular pump is connected with the vacuum chamber, and the exhaust port of the rear-stage molecular pump is connected with the suction port of the front-stage mechanical pump through an electric control valve; the exhaust port of the front-stage mechanical pump is connected with the external atmospheric environment. The vacuum sensor is used to detect the vacuum degree in the vacuum chamber, and the vacuum sensor is arranged in the vacuum chamber or communicated with the vacuum chamber. The signal input interface of the control unit (such as a single-chip microcomputer controller) is respectively connected w...

Embodiment 2

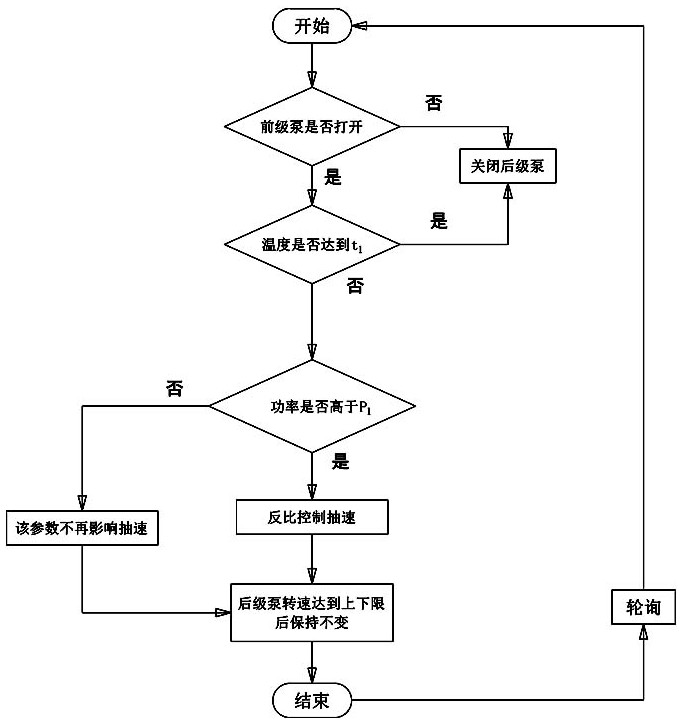

[0067] Such as image 3 As shown, this embodiment provides another control method for the back-stage pump control system of the vacuum system described in Embodiment 1, including:

[0068] Step 1. The control unit judges whether the back-stage pump is turned on. Only after the front-stage pump is turned on, the control unit can control the opening of the electric control valve and the back-stage pump, so as to avoid damage to the back-stage pump when it is turned on alone;

[0069] Step 2, when the back-stage pump is turned on, the control unit reads the working temperature t, output power P and rotational speed n of the back-stage pump in real time through the built-in temperature sensor of the back-stage pump and the controller of the back-stage pump;

[0070] When the working temperature t of the back-stage pump is higher than or equal to the first preset temperature t 1 , it means that the working temperature of the back-stage pump is too high. Working in this state will ...

Embodiment 3

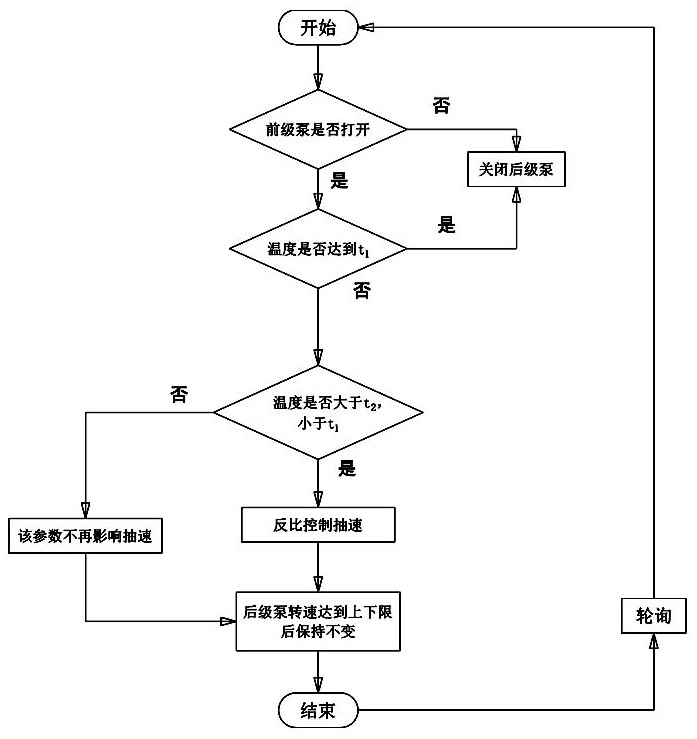

[0079] Such as Figure 4 As shown, this embodiment provides another control method for the back-stage pump control system of the vacuum system described in Embodiment 1, including:

[0080] Step 1. Determine whether the back-stage pump is turned on. Only after the front-stage pump is turned on, can the electric control valve and the back-stage pump be turned on;

[0081] Step 2, when the back-stage pump is turned on, the control unit reads the working temperature t of the back-stage pump and the vacuum degree in the vacuum chamber in real time through the temperature sensor arranged in the back-stage pump and the vacuum sensor of the back-stage pump;

[0082] When the working temperature t of the back-stage pump is higher than or equal to the first preset temperature t 1 , the control unit shuts down the back-stage pump through the controller of the back-stage pump;

[0083] When t 1 , indicating that the temperature of the back-stage pump is in the safe operating range. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com