Manual sorting equipment

A kind of artificial and equipment technology, applied in the field of manual sorting equipment, can solve the problems of inability to meet the needs of intensive sorting and high-efficiency sorting in sorting centers, reduce the difficulty of sorting, solve the problem of large space, and improve sorting. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

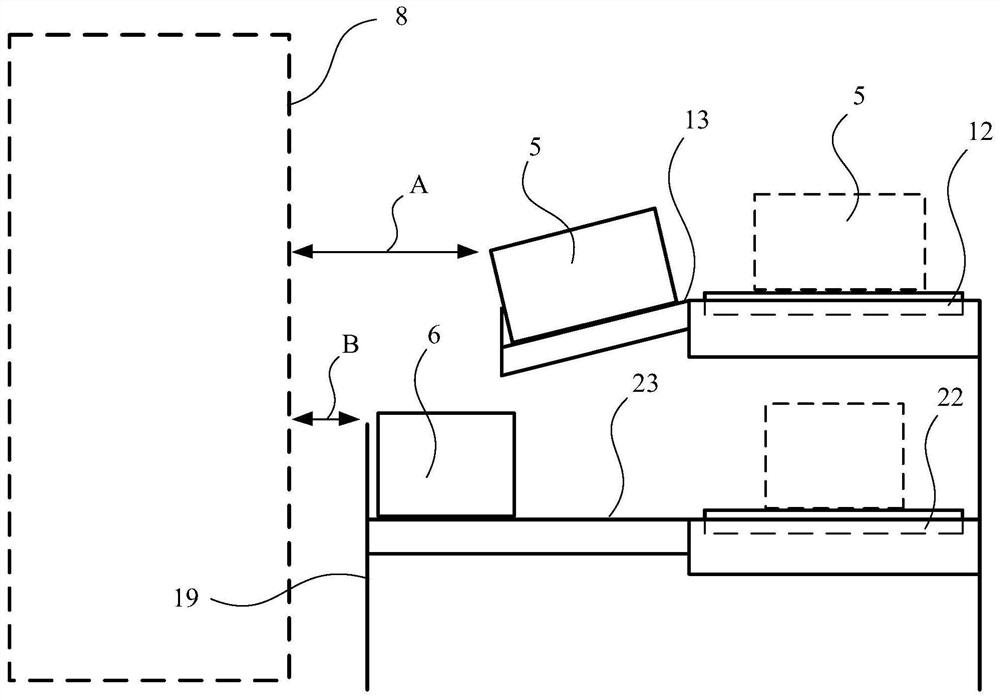

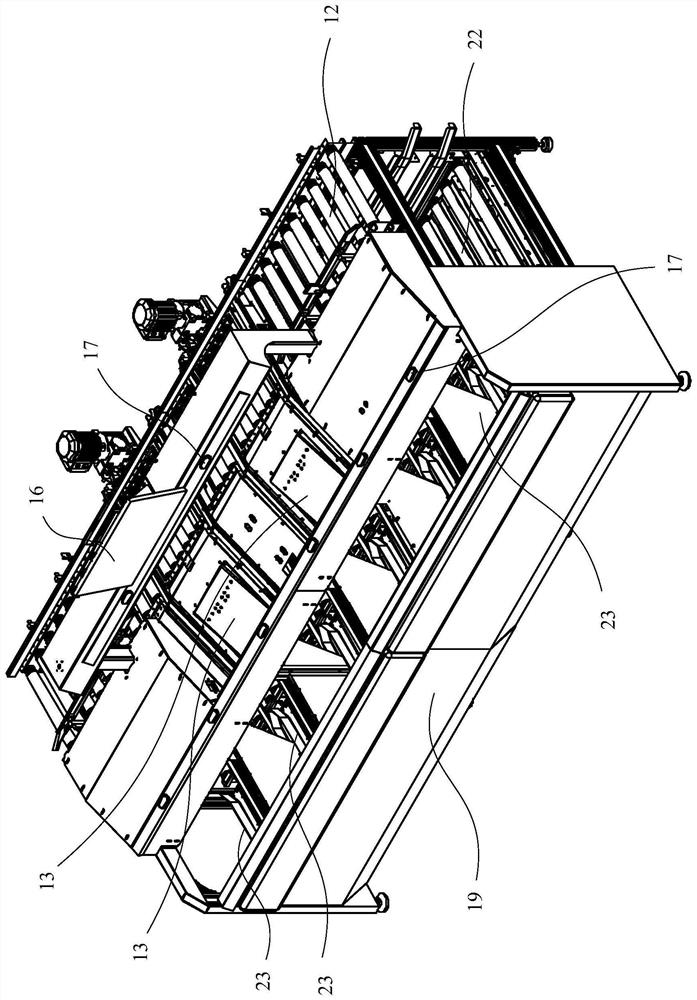

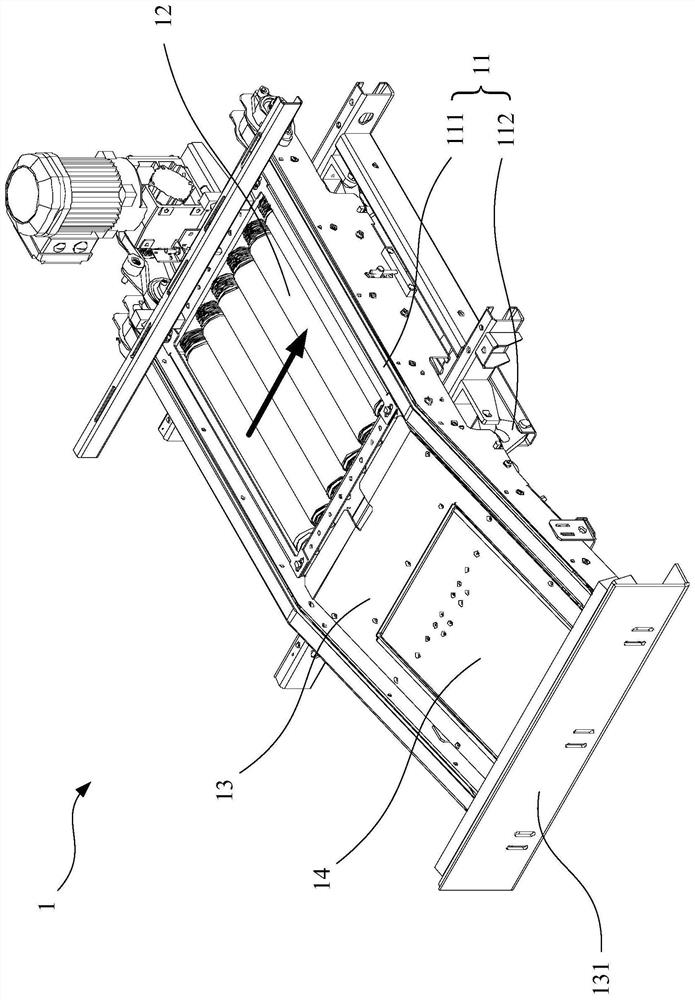

[0057] Such as figure 1 , image 3 with Figure 5 As shown, the present invention provides a manual sorting device, which specifically includes a feeding conveying line 1 and a receiving conveying line 2 . Wherein, the feeding conveying line 1 has a feeding moving mechanism 11, and the feeding moving mechanism 11 is used to transport the storage container 5 between the feeding conveying line body 12 and the feeding picking platform 13 of the feeding conveying line 1, and the receiving The item conveying line 2 also has a material receiving moving mechanism 21 correspondingly, and the material receiving moving mechanism 21 is used to carry the target container 6 between the receiving conveying line body 22 and the receiving picking platform 23 of the receiving conveying line 2, and at the same time, the feeding The conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com