Connector panel connecter installation zone shielding tool and method

A technology for connectors and installation areas, which is applied in the field of shielding tooling in the installation area of connectors, and can solve problems such as affecting coating quality, film sticking offset, and being difficult to find.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

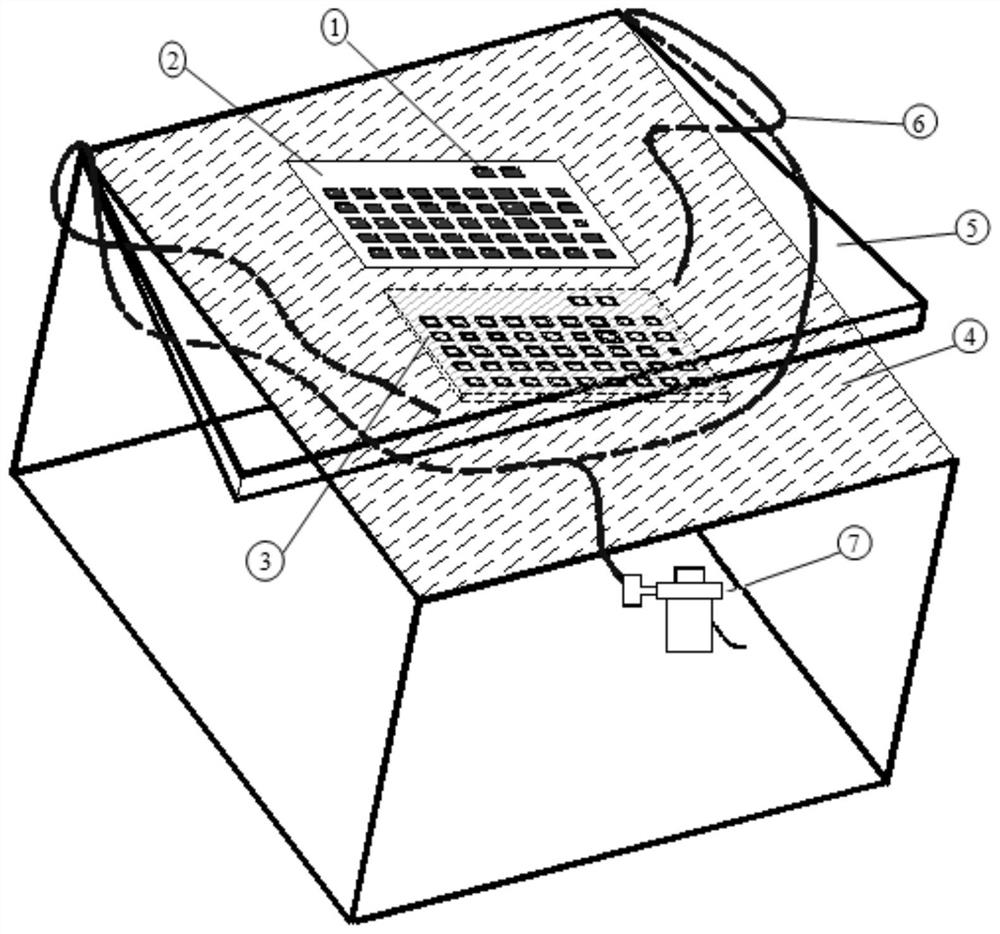

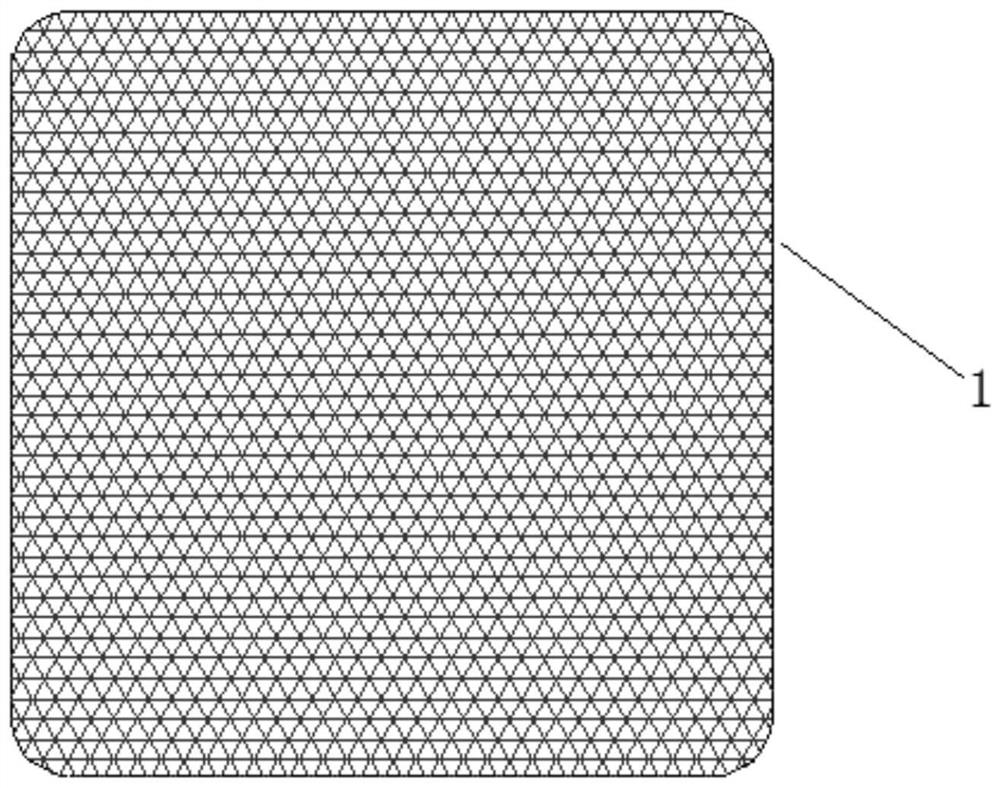

[0032] The invention relates to a tool and method for shielding the connector installation area of the connector panel when coating the case of electronic equipment. The tool is as follows: figure 1 As shown, it includes a film 1, a template 2, a workbench 4, a cover plate 5, a hose 6 and an air suction device.

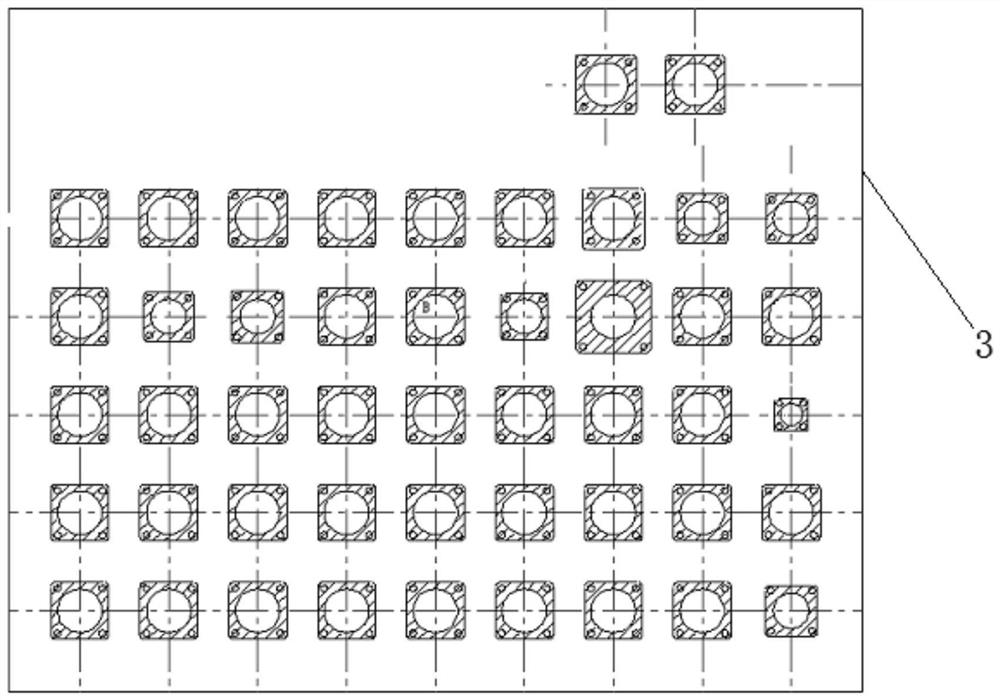

[0033] The workbench 4 is used to carry the connector panel 3 and the template 2, the workbench 4 is hinged with the cover plate 5, the lower surface of the cover plate 5 is fixed with a rubber sheet, and the air inlet of the suction device is connected with a hose 6.

[0034] The lower surface of the template 2 is provided with a groove having the same shape as the connector panel 3, the depth of the groove is equal to or less than the thickness of the connector panel 3, and the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com