A hand-held peanut crushing equipment

A hand-held peanut technology, which is applied in the field of hand-held peanut quick crushing equipment, can solve the problems of slow crushing speed and achieve the effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

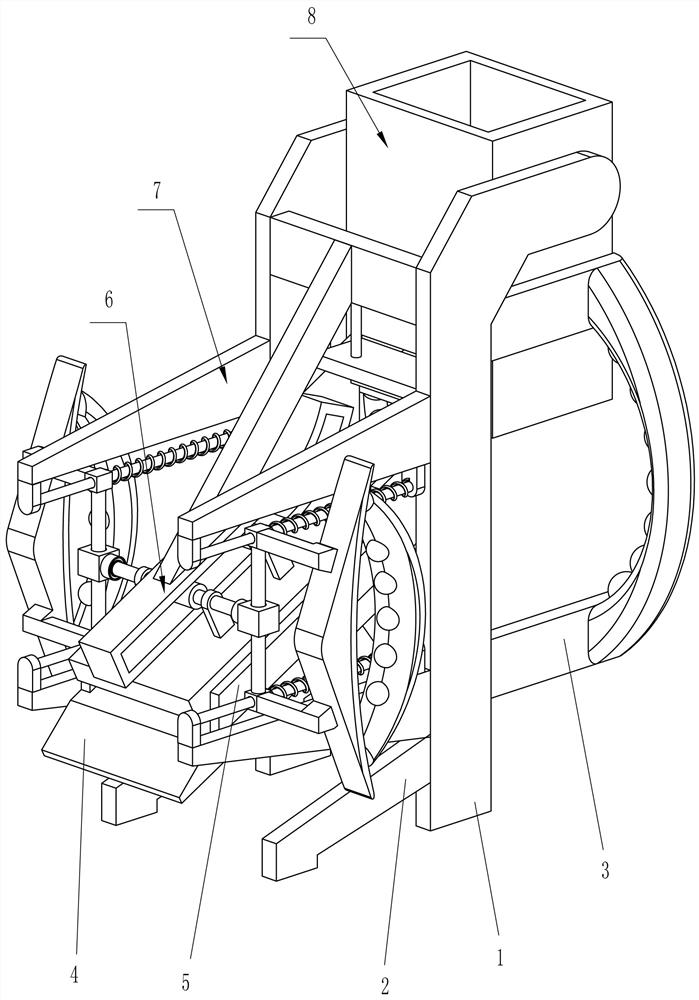

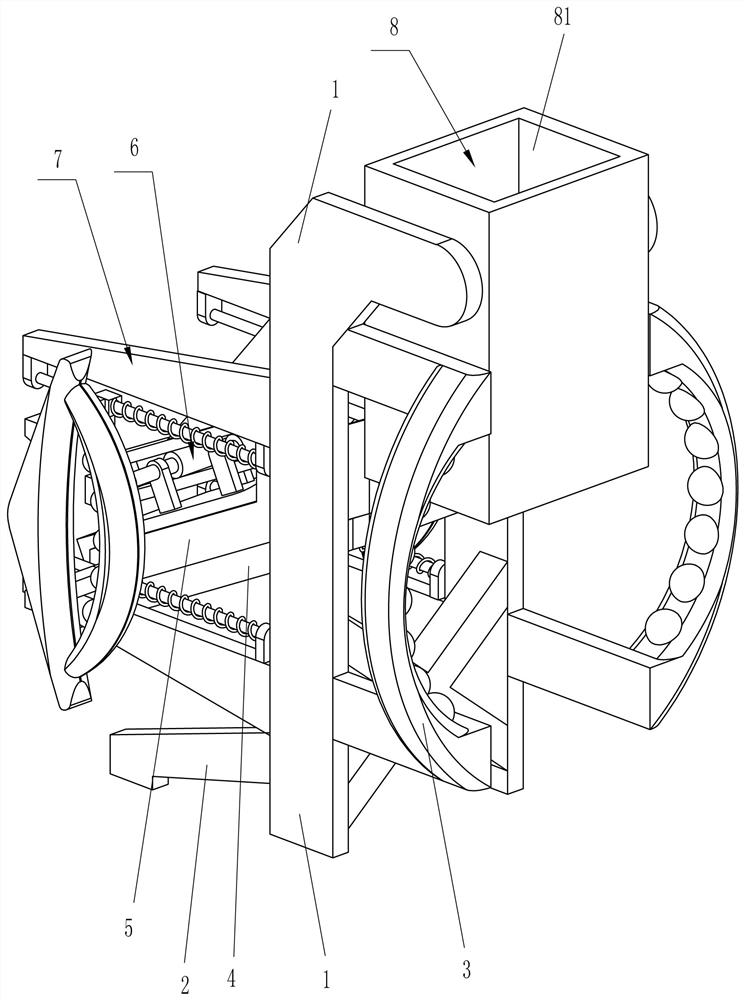

[0023] A handheld peanut rapid crushing equipment, such as Figure 1-2 As shown, it includes a mounting frame 1, a placing frame 2, a fixed handle 3, a processing plate 4, a side plate 5, a rolling device 6 and a transmission device 7, specifically:

[0024] A placing frame 2 is connected to the lower left side of the mounting frame 1, two fixed handles 3 are connected to the right side of the mounting frame 1, a processing plate 4 is connected to the left side of the installation frame 1, and side plates are connected to the front and rear sides of the processing plate 4. 5. A rolling device 6 is arranged above the left side of the mounting frame 1 , and the rolling device 6 is in contact with the processing plate 4 .

[0025] When the peanuts need to be crushed, the device can be held by the fixed handle 3 and the transmission device 7, and then the transmission device 7 can be pulled to the right, and the transmission device 7 will drive the crushing device 6 to move to the...

Embodiment 2

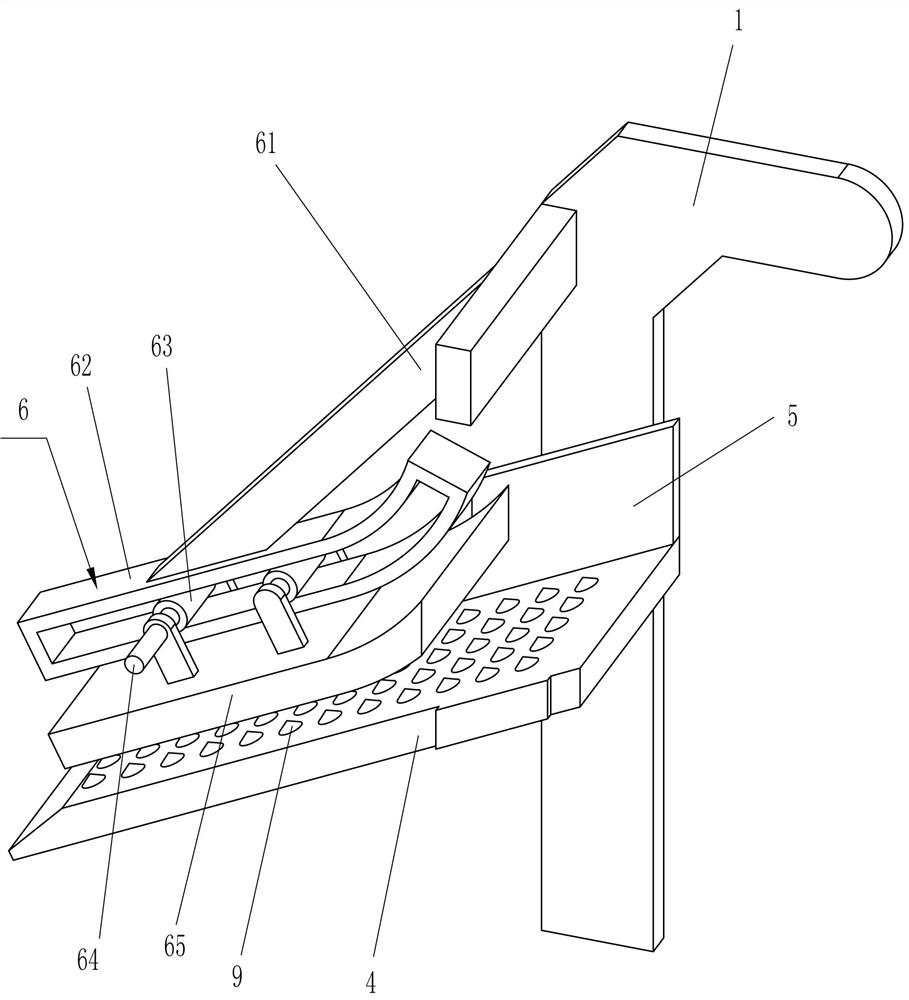

[0027] On the basis of Example 1, as Figure 3-6 As shown, the rolling device 6 includes a connecting rod 61, a slide rail 62, a pulley 63, a connecting shaft 64 and a rolling plate 65, specifically:

[0028] A connecting rod 61 is connected to the upper left side of the mounting frame 1, and a sliding rail 62 is connected to the lower side of the connecting rod 61. The sliding rail 62 has a structure in which the left section of the stroke is a straight line, and the right section of the stroke is an arc. The pulley 63, the front and rear sides of the left pulley 63 are connected with a connecting shaft 64, the connecting shaft 64 is connected with the transmission device 7, and a rolling plate 65 is connected between the lower side of the connecting shaft 64, and the rolling plate 65 is located above the processing plate 4 and not in contact.

[0029] When the transmission device 7 is pulled to move to the right, the transmission device 7 will drive the left connecting shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com