Lifting shifting device for large-scale bridge crane and shifting method

A technology of raising device and shifting device, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as consumption, and achieve the effect of obvious benefits, simple operation and strong competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

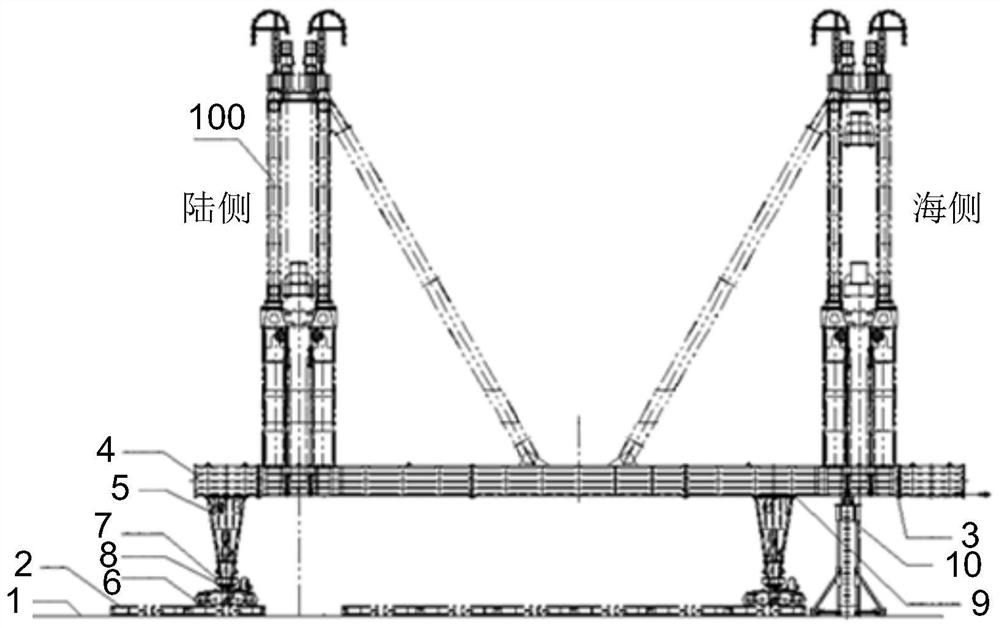

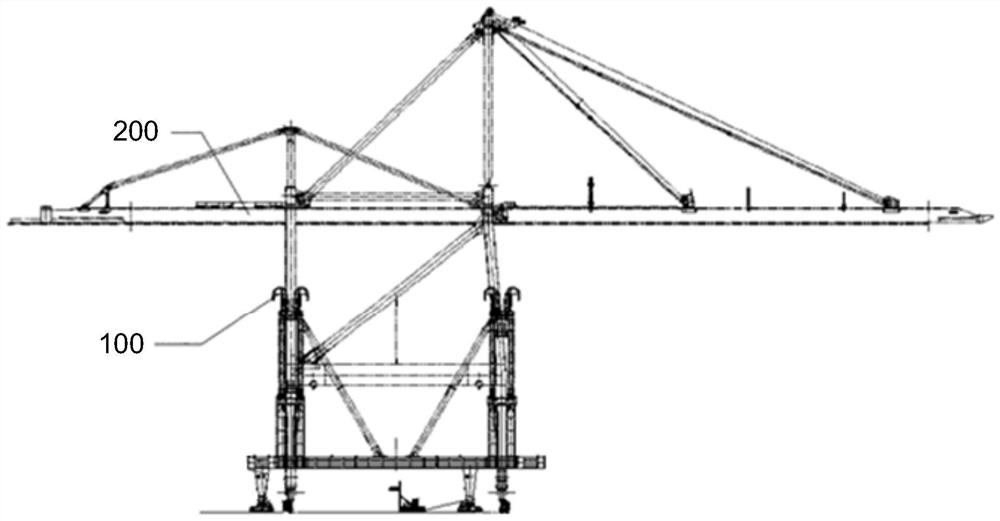

[0037] Please combine Figure 1 to Figure 4 As shown, a lifting and shifting device for a large bridge crane provided by the present invention includes a lifting device 100 and a rail 2 arranged on a dock surface 1 .

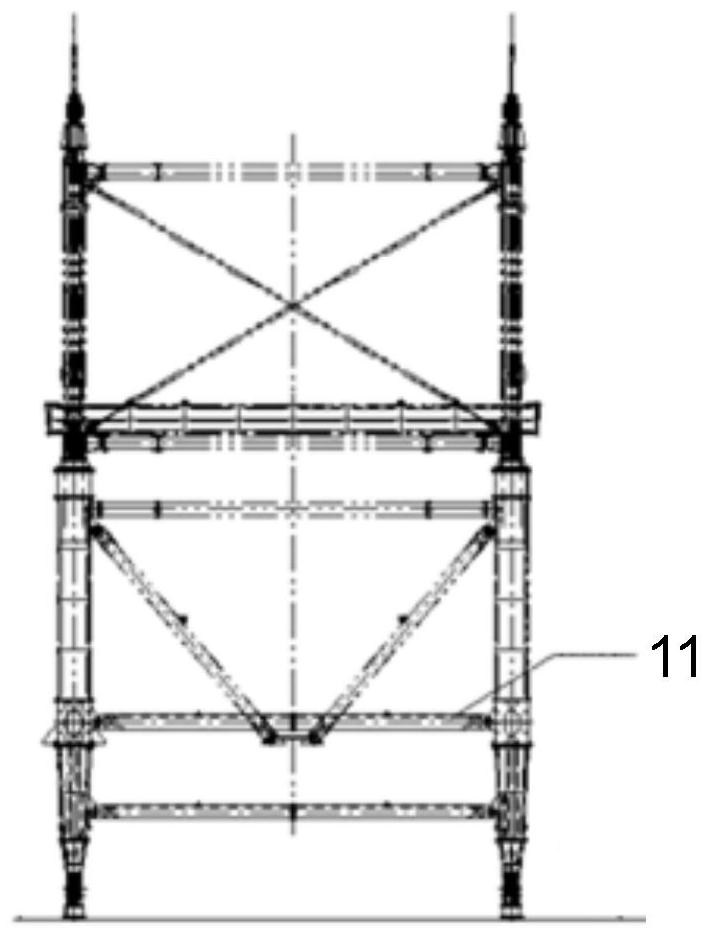

[0038] The bottom of the elevating device 100 has two pressure beams 3 arranged in parallel, and the two pressure beams 3 are connected by a lateral stabilizer 11. The elevating device 100 needs to be strengthened, and the elevating device 100 needs to be strengthened by using a lateral stabilizer 11. Stabilize and strengthen the pressure beam 3 .

[0039] Both ends of the two pressure beams 3 are connected with long pressure beams 4 to increase the length of the pressure beams 3 .

[0040] The prosthetic leg 5 is connected on the long pressure beam 4 .

[0041] A jacking trolley 6 is provided on the track 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com