A rotating seat for electromechanical installation engineering

A technology of electromechanical installation engineering and swivel seat, which is applied in the direction of transportation and packaging, load hanging components, etc., and can solve problems such as improper size, difficult manual measurement, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

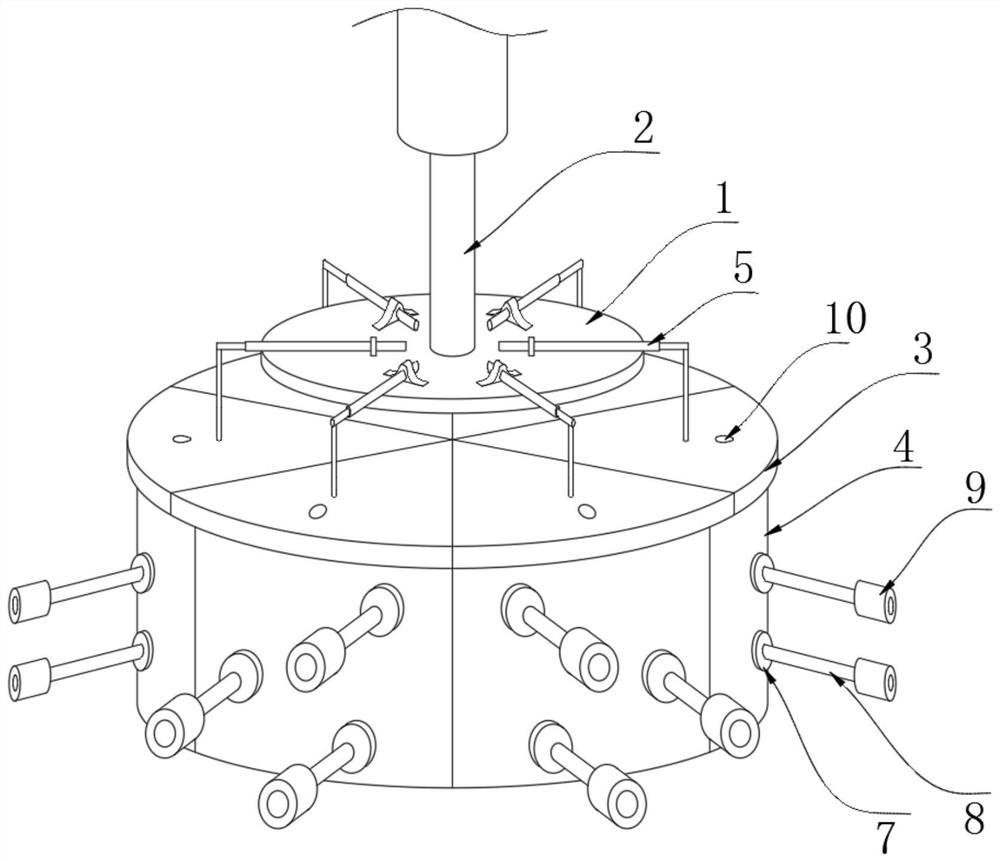

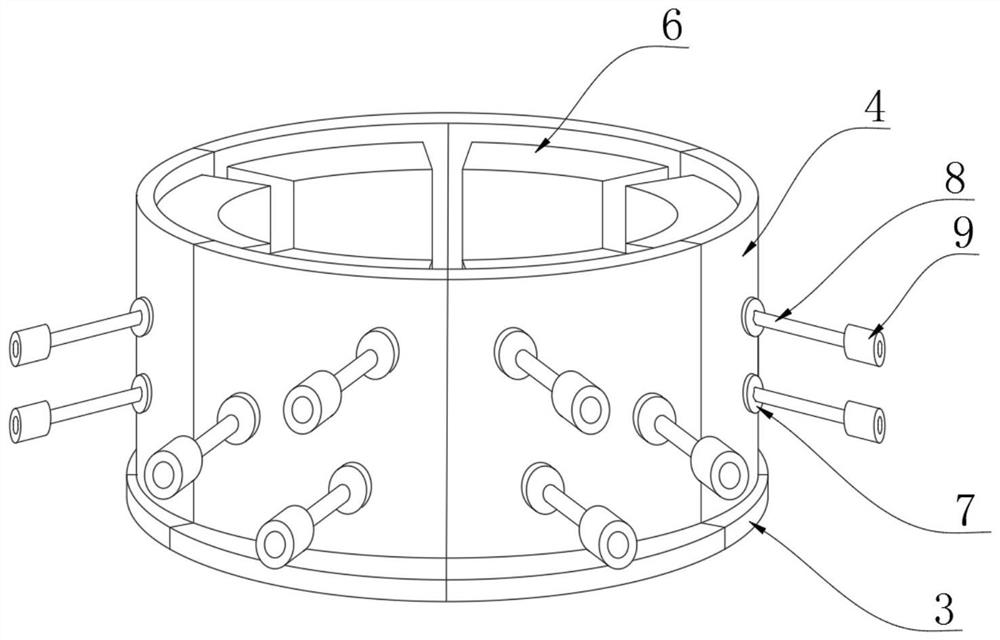

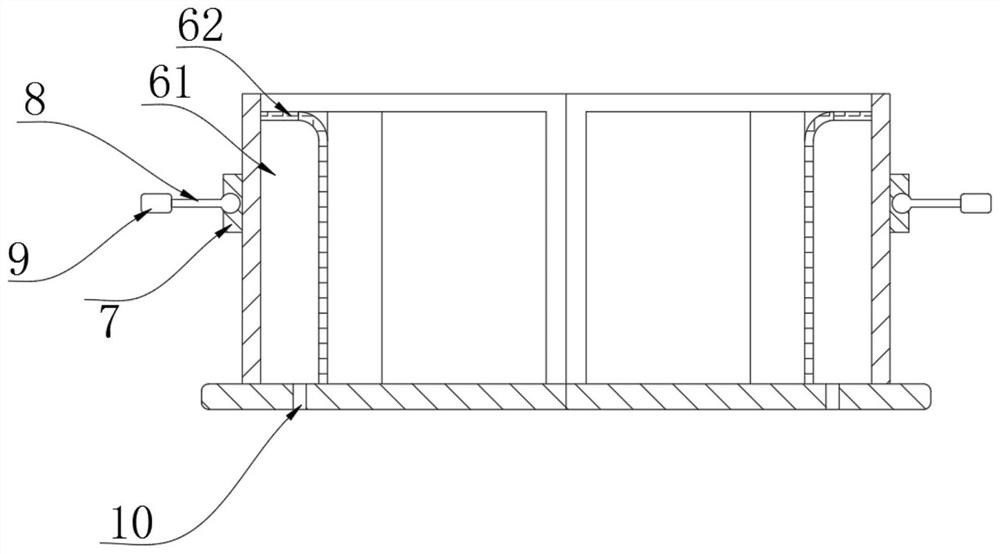

[0024] refer to Figure 1-5 , a rotating seat for electromechanical installation engineering, including a rotating disk 1 and a telescopic cylinder 2 rotatably connected to its upper surface. The telescopic cylinder 2 is connected to an external equipment rack. The strength is to facilitate the lifting of the electromechanical equipment in the later stage. The rotating disk 1 takes its geometric center as the center point, and a plurality of push rods 5 are fixed on the circumference symmetrically. The output end of each push rod 5 is fixedly connected with a fan-shaped plate 3 through a fixed rod. , a plurality of fan-shaped plates 3 offset each other to form a disc, and each fan-shaped plate 3 is fixedly connected with a side plate 4, and a plurality of side plates 4 offset each other to form a ring, that is, when the fan-shaped plates 3 and the side plates 4 are close to each other, they can To form a cylindrical structure, the inner wall of each side plate 4 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com