Rotational flow type air inlet porous medium combustor used for gentle heating photoelectricity

A porous medium, micro-thermal photoelectric technology, applied in the direction of gas fuel burner, burner, combustion type, etc., can solve the problems of uneven temperature distribution, low energy conversion rate, low combustion efficiency, etc., to increase the probability of collision, combustion Full, complete combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

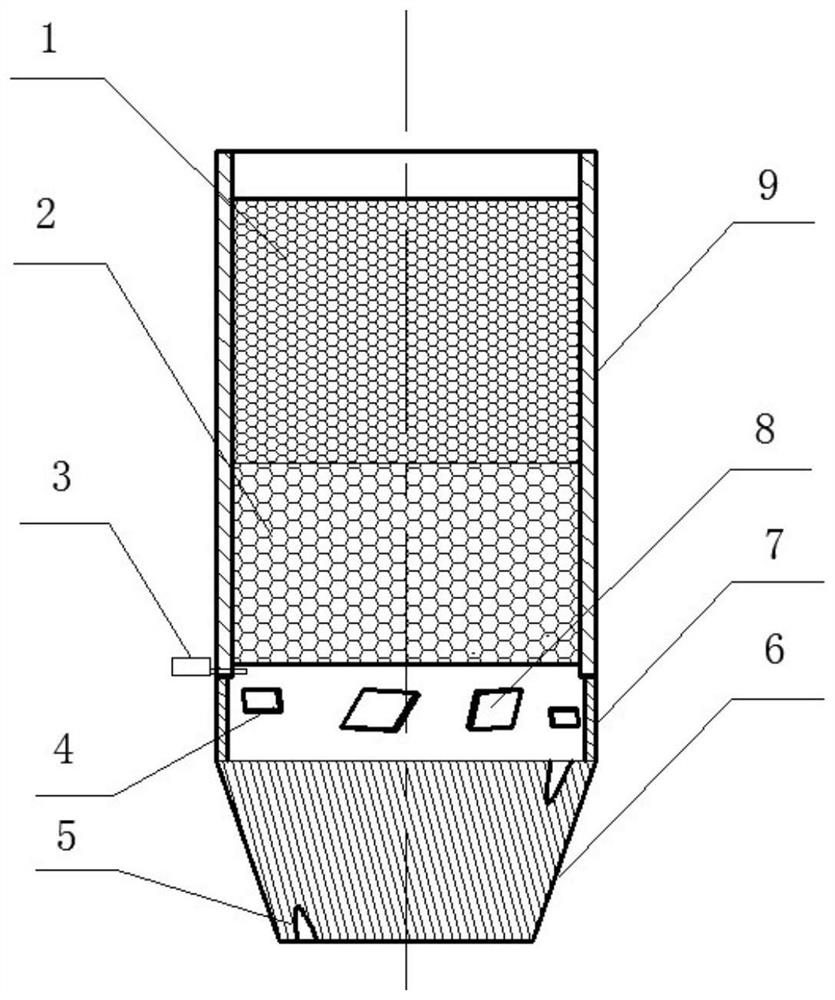

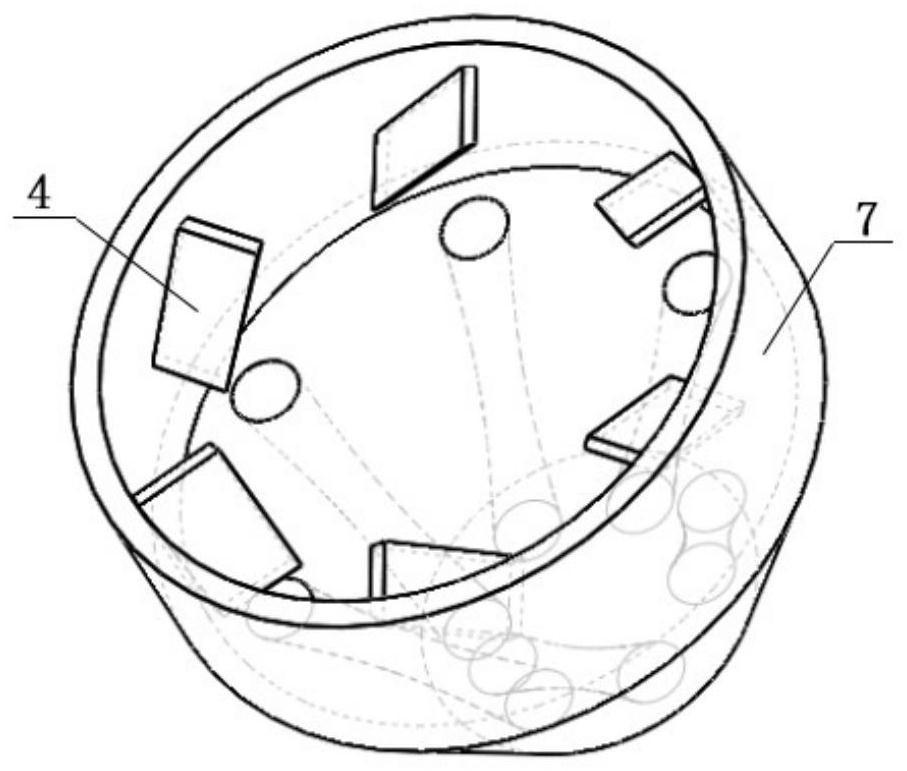

[0025] like figure 1 and figure 2 As shown, the swirling air intake porous media burner for micro-thermophotovoltaic according to the present invention includes an intake area 6, a combustion area 9 and a premixing area 7, and the premixing area 7 is located in the intake area 6 and between the combustion zone 9, the shape of the air intake area 6 is an inverted circular table, at least six air intake passages 5 are evenly distributed in the air intake area 6, and the inlet and outlet of any one of the air intake passages 5 are in the Circumferentially offset, the inclination angle of the axis of the air intake duct 5 is 20° to 60°, that is, assuming that the inlet of the air intake channel 5 is at the circumferential 0 degree position of the small end face of the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com