Liquid level switch

A technology of liquid level switch and micro switch, which is applied in the direction of buoy liquid level indicator, liquid/fluid solid measurement, robot floating motion actuation, etc. problems, to achieve the effect of free maintenance, online self-inspection, and avoiding false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

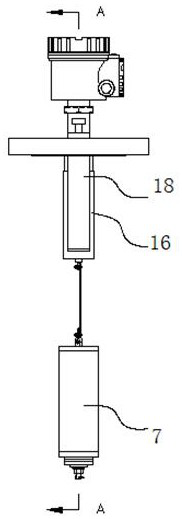

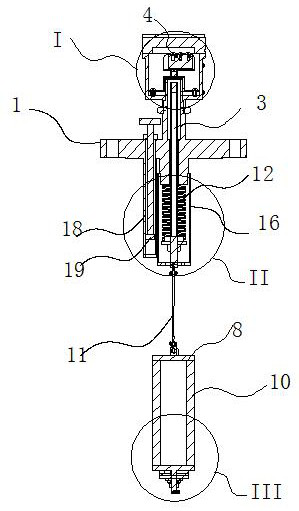

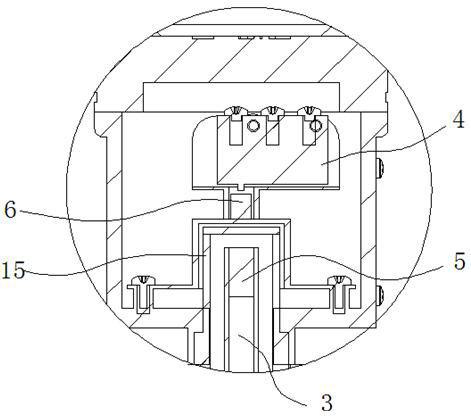

[0029] Such as Figure 1 to Figure 5 As shown, a liquid level switch includes a mounting base 1 installed on the storage tank, the mounting base 1 is provided with a guide hole, and an inner guide rod 3 is movably installed in the guide hole, and the mounting base is fixed on the A micro switch 4 is installed, and an inner magnetic steel 5 is fixedly installed on the upper end of the inner guide rod 1, and the inner magnetic steel 5 and the micro switch 4 are provided between the inner magnetic steel 5 and the micro switch 4 to trigger the micro switch when moving upward The upper drive magnet 6, the magnetic pole of the lower end of the upper drive magnet 6 is the same as the magnetic pole of the upper end of the inner magnet 5; it also includes a floating mechanism that drives the inner guide rod to move upward when the liquid level in the storage tank rises. mechanism. The inner magnet and the upper drive magnet adopt the principle of magnetic coupling drive. The inner mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com