System used for improving automatic control of machine operations of construction site machinery

A technology for machine control and machine operation, used in control/regulation systems, non-electric variable control, motor vehicles, etc., to solve problems such as loss of sight contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

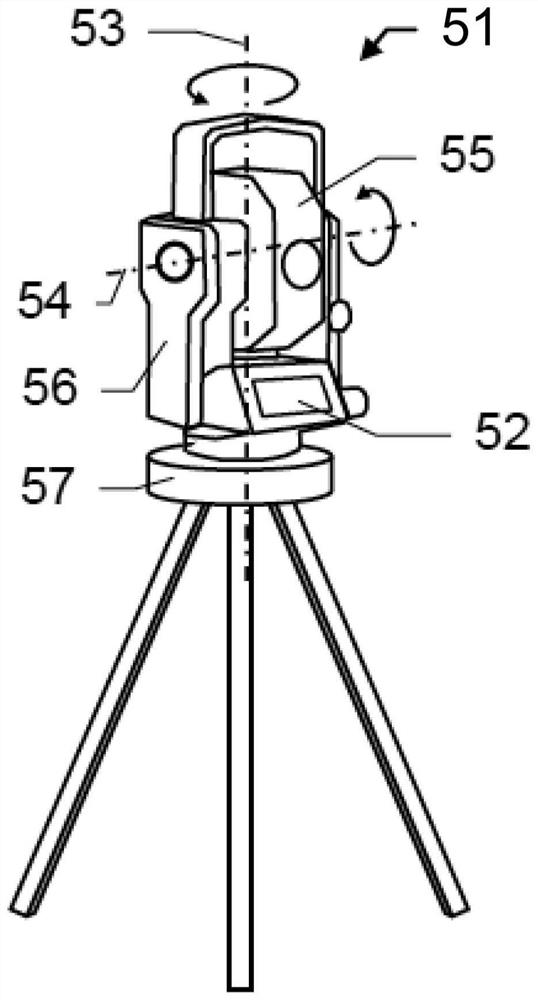

[0021] figure 1 A total station or theodolite 51 according to the prior art is shown, in this case the total station 51 comprising a tracking unit 55 with an image acquisition unit (here exemplary a panoramic camera), wherein , the acquisition direction of the image acquisition unit is largely parallel to the measurement direction of the measuring device also arranged in the total station or theodolite. The light acquisition axis of the integrated image acquisition unit therefore extends at least parallel to, in particular coaxial with, the measurement axis defined by the measurement radiation that can be emitted. The field of view of the image acquisition unit is limited by the optical unit installed in the tracking unit 55 and by the configuration of the tracking unit 55 , wherein the measurement radiation is likewise emitted through the optical unit and thus the direction of the measurement radiation is limited.

[0022] Furthermore, the total station or theodolite 51 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com