A municipal sewage pipe cleaning device

A technology for cleaning devices and municipal sewage, applied to water supply devices, cleaning sewer pipes, waterway systems, etc., can solve problems such as poor working environment, low work efficiency, and impossible to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

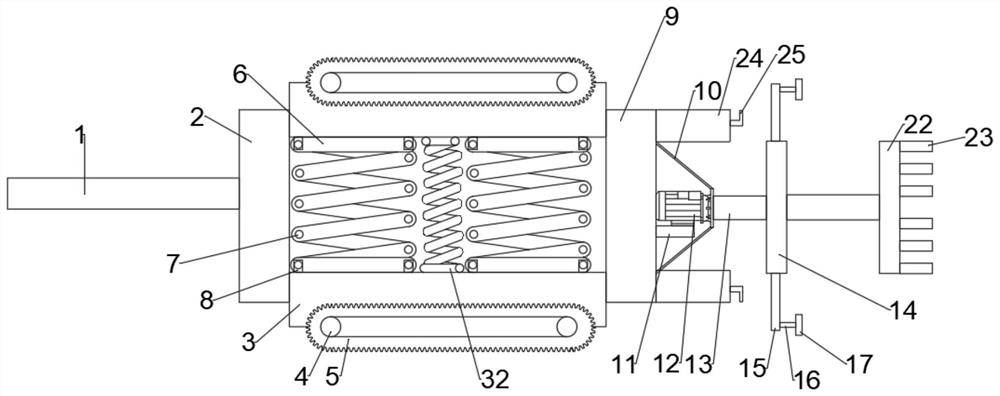

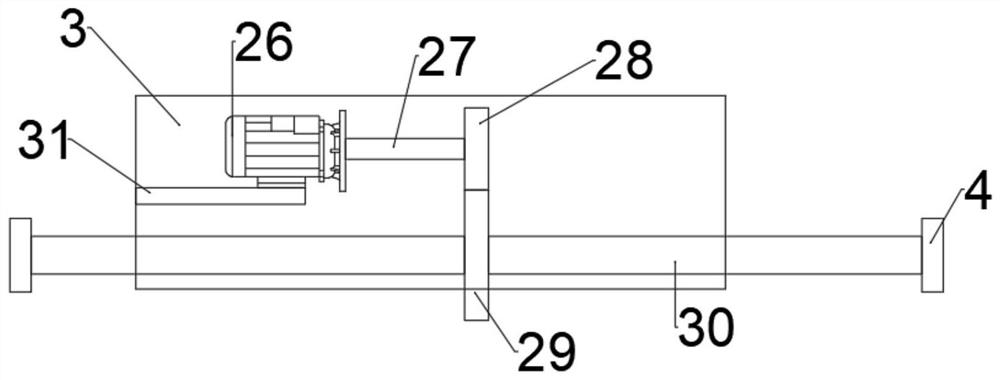

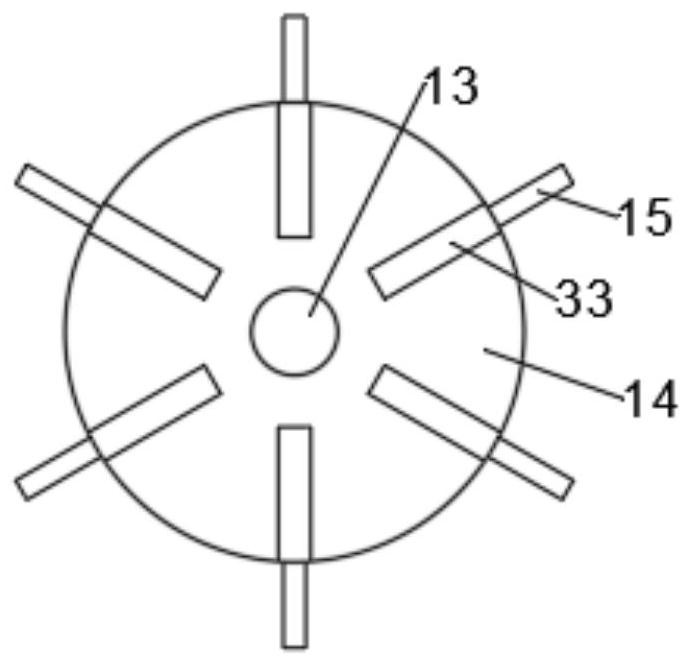

[0032]ReferFigure 1 ~ 3 A municipal sewage pipe cleaning device comprising a left connection block 2, and the upper and lower ends of the left connecting block 2 are slidably connected to the bottom plate 3, and the two bottom plate 3 is bolted with a first fixing plate 8, The first fixing plate 8 is connected to the connecting rod 6, and the two connecting rods 6 are connected between the two connecting rods 6, and the two bottom plate 3 is connected through the air spring 32, and the right side of the bottom plate 3 is slidable. The connection block 9, the right bolt of the right connection block 9 is connected to the cleaning mechanism, and the internal front side bolt of the bottom plate 3 is connected to the third fixing plate 31, and the upper bolt of the third fixing plate 31 is connected to the travel motor 26, the travel motor 26 The output terminal shaft is connected to the first row shaft 27. The first row shaft 27 is fixed from one end shaft of the traveling motor 26, an...

Embodiment 2

[0040]ReferFigure 4 ~ 5, A municipal sewage pipe cleaning device, this embodiment is provided with a slide groove 21 in the left side of the right connecting block 9, and the front and rear sides of the chute 21 are opened on both sides of the left side, and the bottom plate 3 is opened. The side bolt is connected to a sliding table 18. The front and rear side of the slide table 18 is bolted to connect the finite block 19, and the sliding stage 18 slides in the chute 21, the limit block 19 slides in the limit slot 20, using the slide table 18 and the chute 21 so that the bottom plate 3 is more stable when adapting to different sewage pipes, and the device is not operated when the device is not operating, and does not make the bottom plate 3 out of the right connection block when the device is not operating, using the limit block 19 and the restricted groove 20. 9, increasing its stability.

[0041]Working principle: Using the sliding table 18 and the chute 21 so that the bottom plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com