Combined swivel support for bridge construction

A bridge construction and swivel technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as inconvenient installation, difficult disassembly of templates, poor stability, etc., to ensure shock resistance and cushioning effect, and convenient combined installation , Improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is a further detailed description through specific implementations:

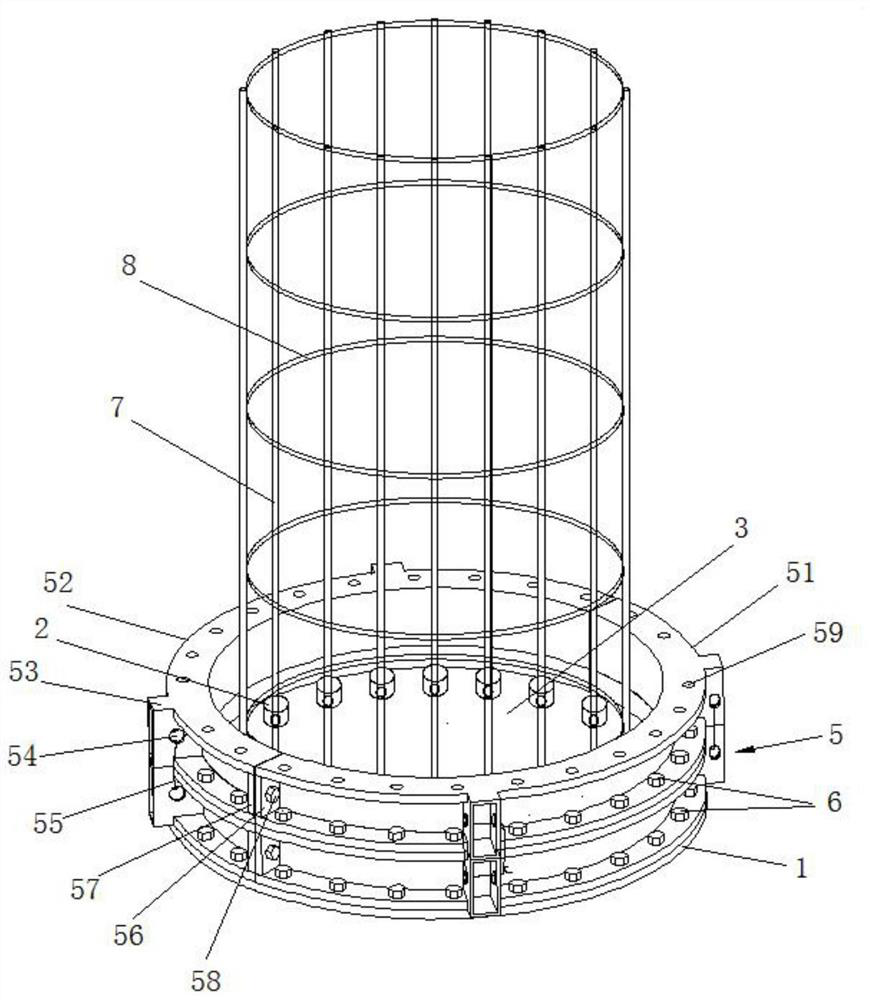

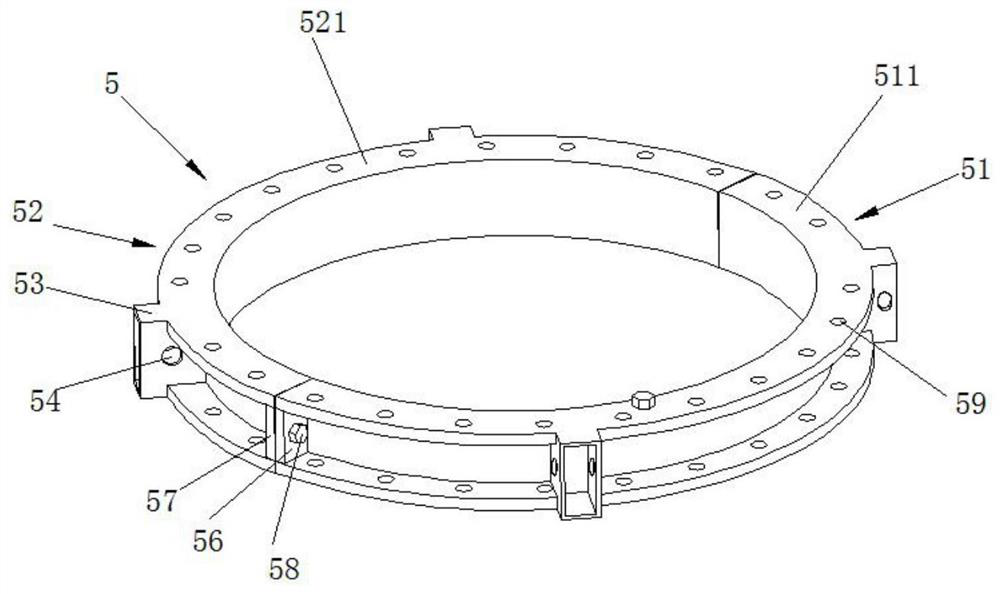

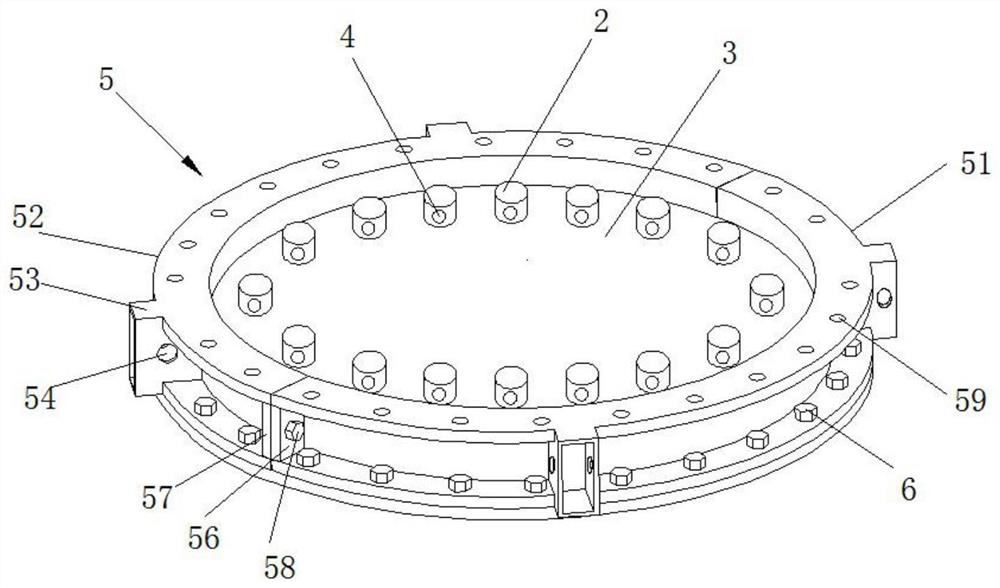

[0032] Such as Figure 1~7 The shown combined swivel support for bridge construction includes a circular support base plate 1. The upper edge of the circular support base plate 1 is fixed with two or more circular side support templates superimposed from bottom to top. 5. The circular side support templates 5 are fixedly connected to the circular support base plate 1 by fixing bolts 6; the circular side support templates 5 are fixedly connected by fixing bolts 6; the upper surface of the circular support base plate 1 is fixed with A number of limit guide posts 2 arranged in the circumferential direction. The limit guide posts 2 are respectively sleeved with rigid springs 9, and the limit guide posts 2 are equipped with limit support discs 3, and the upper ends of the limit guide posts 2 are respectively provided The clamping through holes 4 are respectively clamped and fixed with longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com