Integral tensioning installation method for I-shaped beam

A technology of overall tensioning and installation method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve problems such as heavy jacks, easy shaking of spreaders, and difficult cooperation between jacks and steel strands, etc., to reduce falls risk, prevent sagging, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

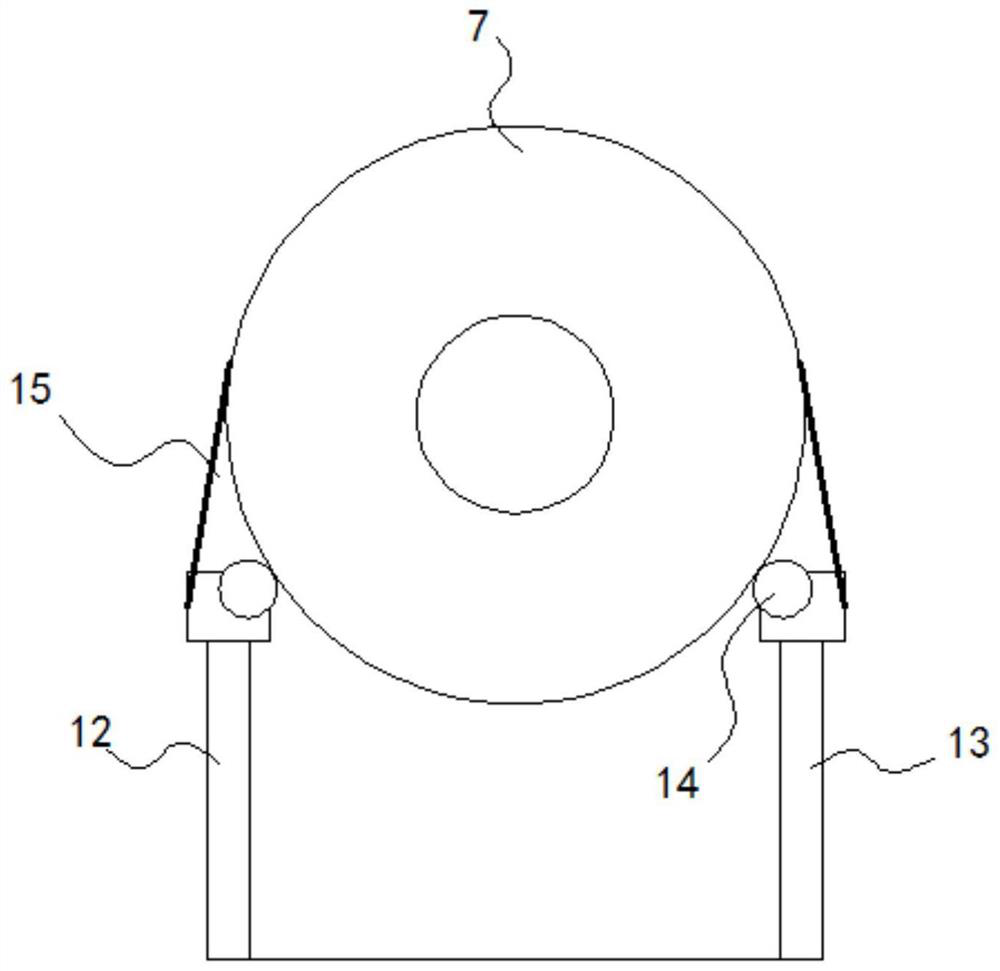

[0047] Such as Figure 1~5 As shown, a kind of I-beam integral tension installation method includes:

[0048] Step 1, designing a special trolley for tensioning, the special trolley for tensioning includes:

[0049] The support includes a base plate 1, a column 2, a telescopic support mechanism 6 and a support platform 4, bottom wheels are arranged below the base plate 1 so that the support can move, the column 2 is vertically arranged on the base plate 1, and the telescopic support Mechanism 6 is arranged on the base plate 1 and the top supports the support platform 4, the top surface of the base plate 1 and the bottom of the support platform 4 are respectively provided with an upper track and a lower track, and the top and bottom ends of the telescopic support mechanism 6 are connected with the upper track and the bottom respectively. The lower track cooperates so that the telescopic support mechanism 6 can move along the track and then adjust the support position. Swing u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com