Auxiliary hoisting device special for special-shaped building component and hoisting method thereof

A technology for building components and hoisting devices, applied in building structure, construction, safety devices, etc., can solve problems such as heavy objects spinning, and achieve the effect of improving practicability, safety and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

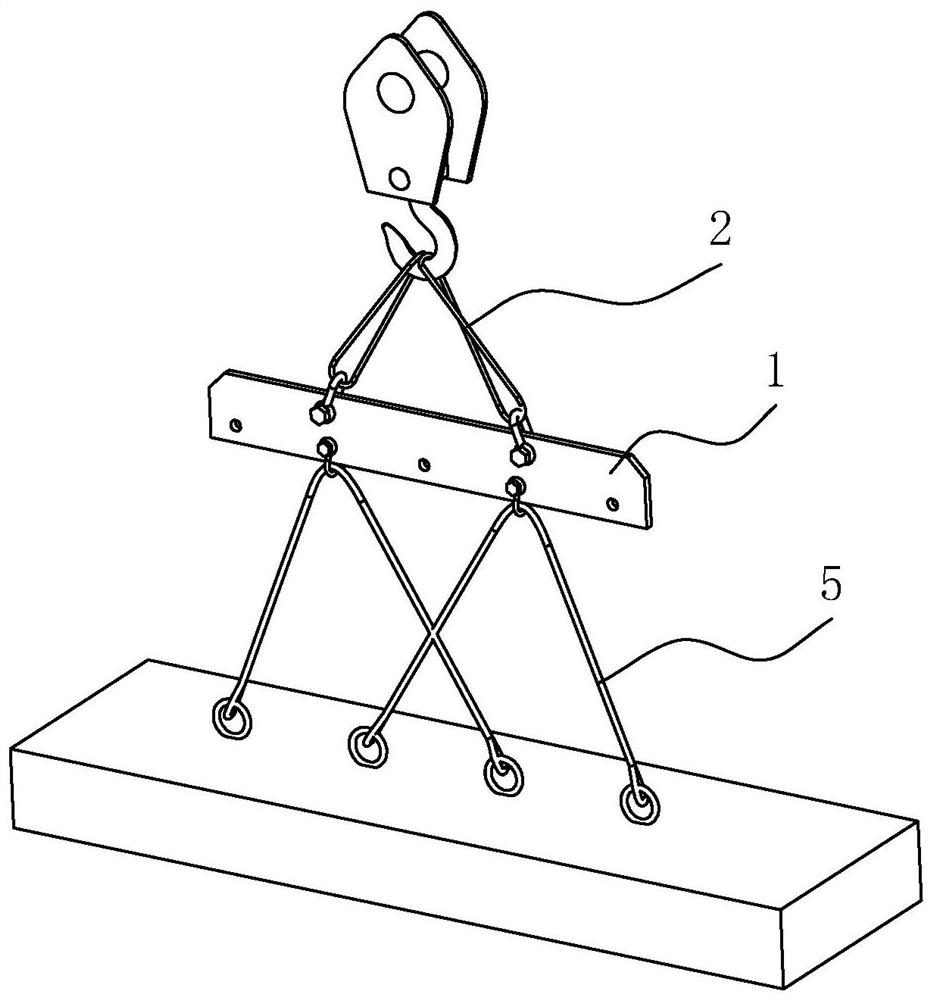

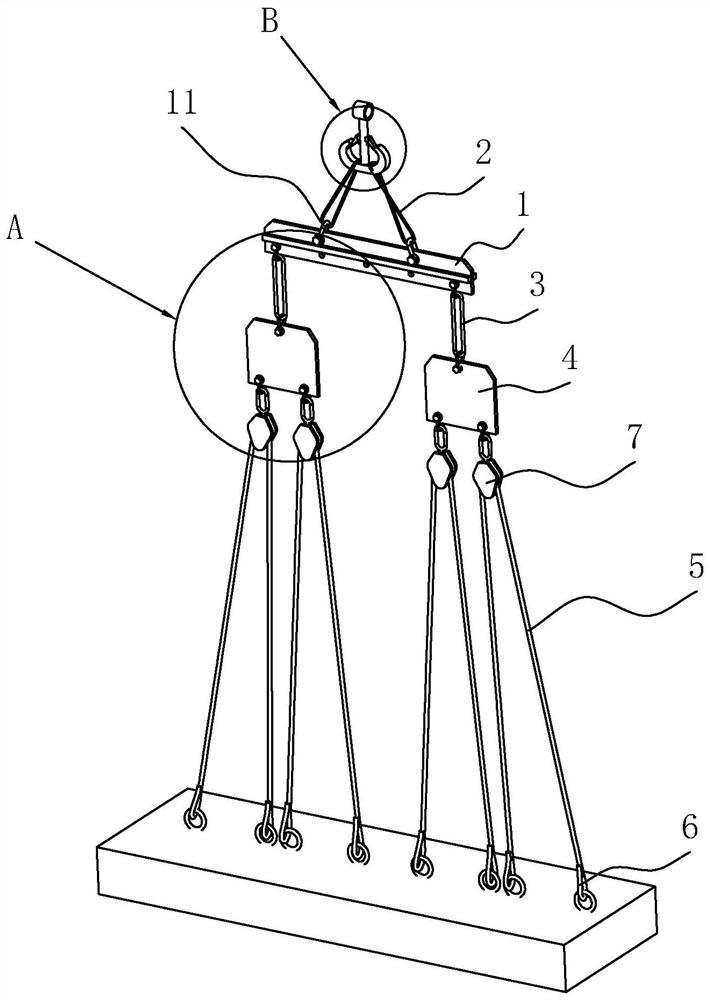

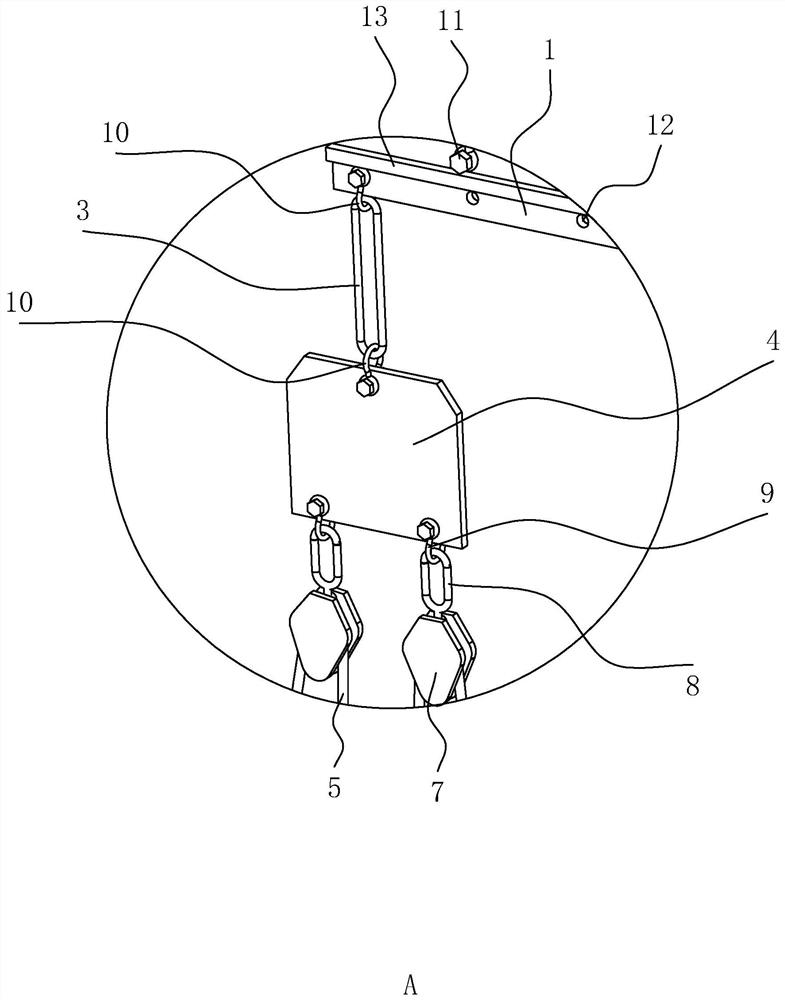

[0045] The embodiment of the present application discloses a special auxiliary lifting device for special-shaped building components. refer to figure 2 and image 3 The auxiliary lifting device for special-shaped building components includes a shoulder pole beam 1, two main suspension ropes 2 are arranged on one side of the length direction of the shoulder pole beam 1, and a plurality of lifting mechanisms are arranged on the side of the shoulder pole beam 1 away from the main suspension rope 2; It includes an auxiliary suspension rope 3 that is rotatably connected to the shoulder pole beam 1, and an auxiliary board 4 is connected to an end of a plurality of auxiliary suspension ropes 3 away from the shoulder pole beam 1, and the auxiliary suspension rope 3 is rotationally connected with the auxiliary board 4, and the auxiliary suspension rope 3 is rotationally connected with the auxiliary board 4, and the auxiliary board 4 is provided with two hook ropes 5 away from the sid...

Embodiment 2

[0057] The embodiment of the present application discloses a hoisting method of a special auxiliary hoisting device for special-shaped building components. refer to Figure 5 The hoisting method of the special auxiliary hoisting device for special-shaped building components comprises the following steps:

[0058] S1. Spreader preparation, set multiple lifting points on the heavy object according to the shape and weight of the heavy object, set the corresponding hook rope 5 and lifting mechanism according to the number of designed lifting points, and install multiple lifting mechanisms on the shoulder beam 1 and a plurality of hoisting mechanisms are arranged symmetrically with respect to the center line in the length direction of the shoulder pole beam 1;

[0059] S2. Hanging posture adjustment, install the two main lifting ropes 2 on the two hooks 15, install the boom 14 on the crane hook, and connect the rings 6 of the multiple hook ropes 5 to multiple lifting points First...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com