Automatic garbage classification equipment

A technology of automatic sorting and garbage, applied in lighting and heating equipment, solid separation, dryers, etc., can solve the problems of reducing the efficiency of screening, injury to sanitation workers, etc., to achieve the effect of improving the effect, ensuring the moving ratio, and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

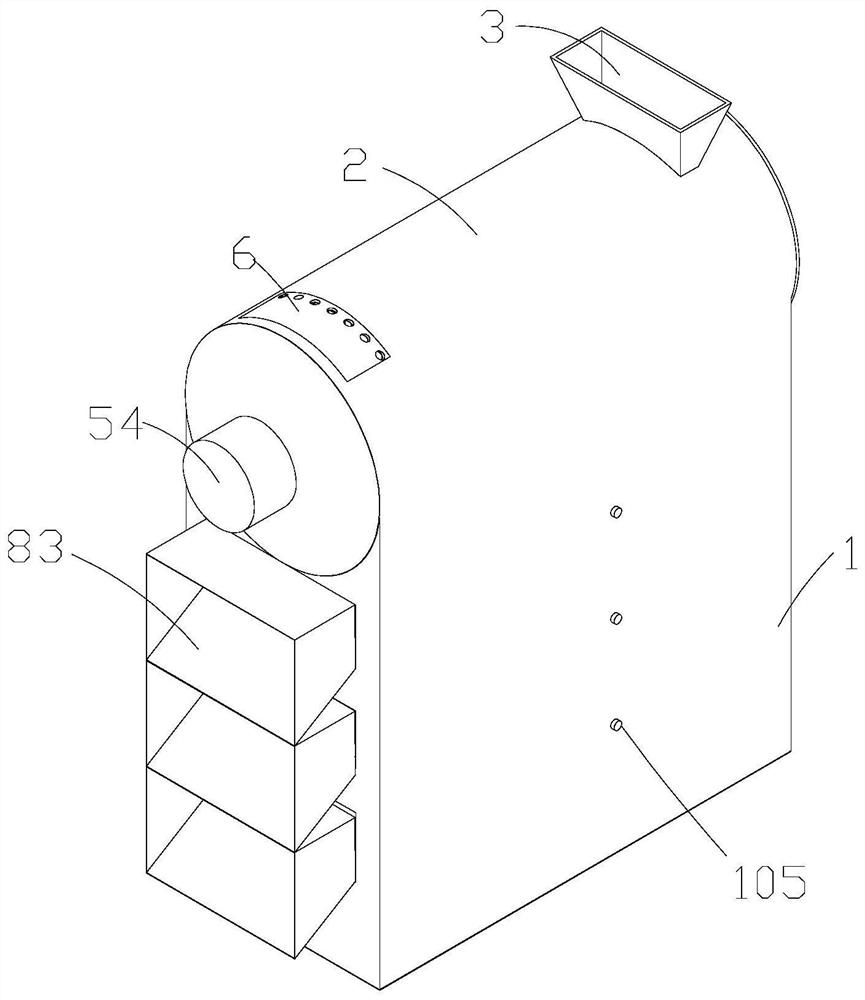

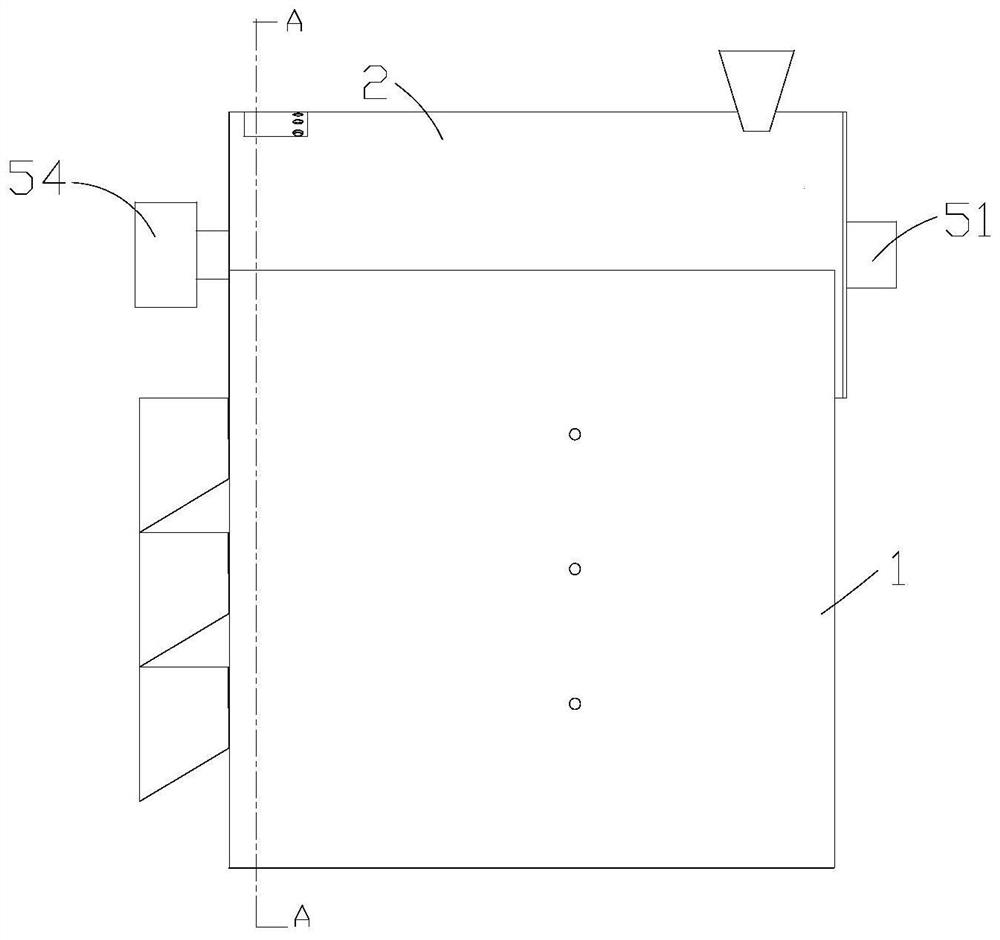

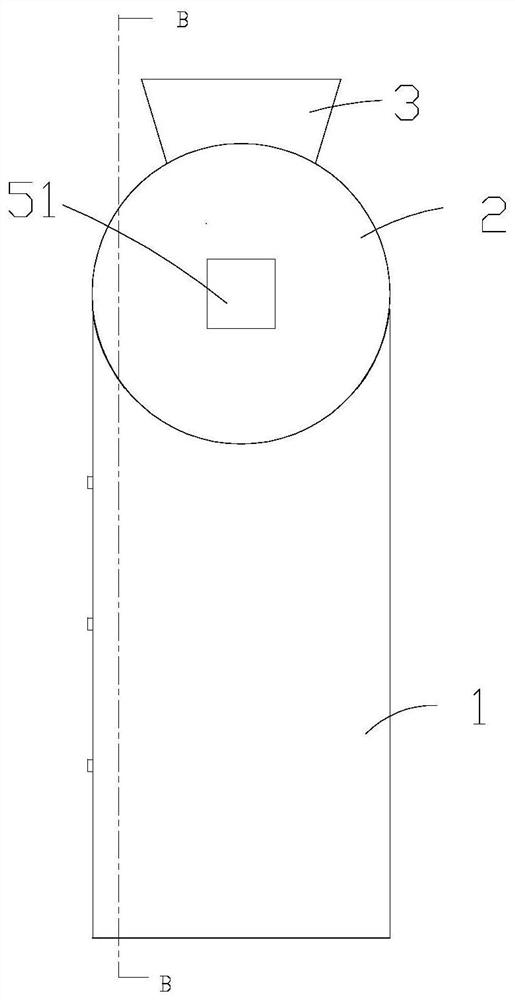

[0036] Such as Figure 1-13 As shown, an automatic garbage sorting device includes a housing 1, a drying channel 2, a feed port 3, a spiral plate 4, a drying device 5, an air outlet 6, a filter screen 7, a screening device 8, and a feeding port 9; the screening device 8 includes a screening mechanism 81, a vibration mechanism 82, a discharge port 83, and a cleaning mechanism 84; the drying channel 2 is set on the housing 1; the feeding port 3 is set on the On the drying channel 2, the longitudinal section of the feeding port 3 is trapezoidal; the spiral plate 4 is a hollow plate, rotatably embedded in the drying channel 2; the drying device 5 is located in the drying channel 2; In the channel 2; the air outlet 6 is located on the drying channel 2, above the feeding port 9; the filter 7 is located below the air outlet 6; the screening device 8 is located on the Inside the casing 1; the feeding port 9 is set in the drying channel 2; the screening mechanism 81 is in two groups, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com