Automatic cap screwing mechanism for cosmetic bottle

A technology for cosmetics and bottle bodies, which is applied to the field of automatic capping mechanisms for cosmetic bottle bodies, can solve the problems that the reliability of cosmetic packaging cannot be guaranteed, the sealing performance of products is affected, and manual operation is required, so as to improve efficiency and general-purpose, avoid Screening and flipping, ensuring the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

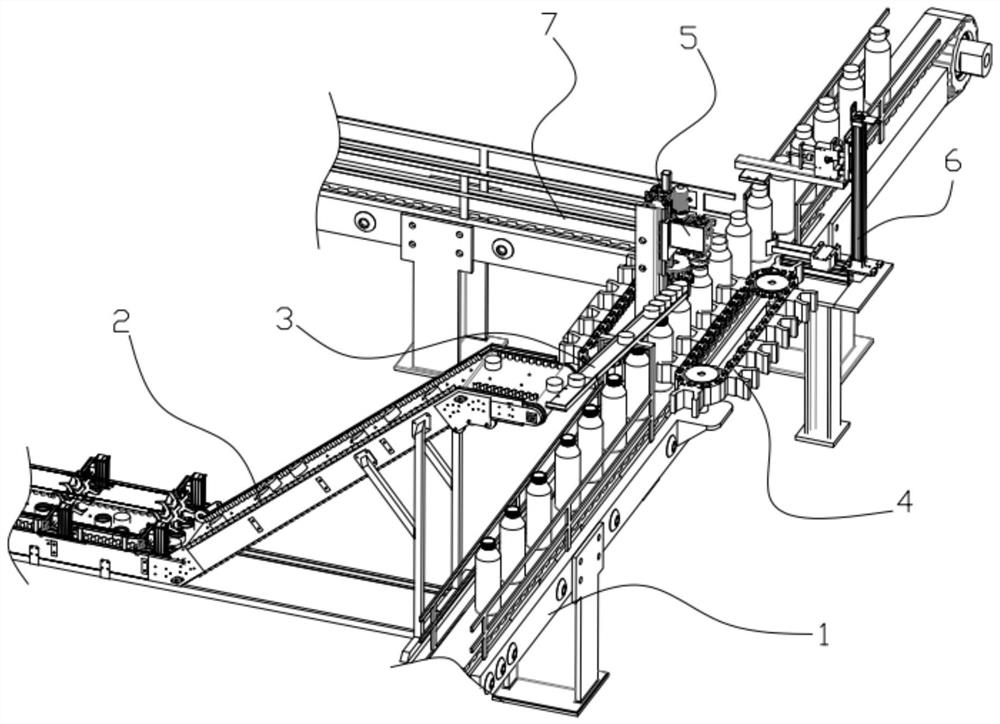

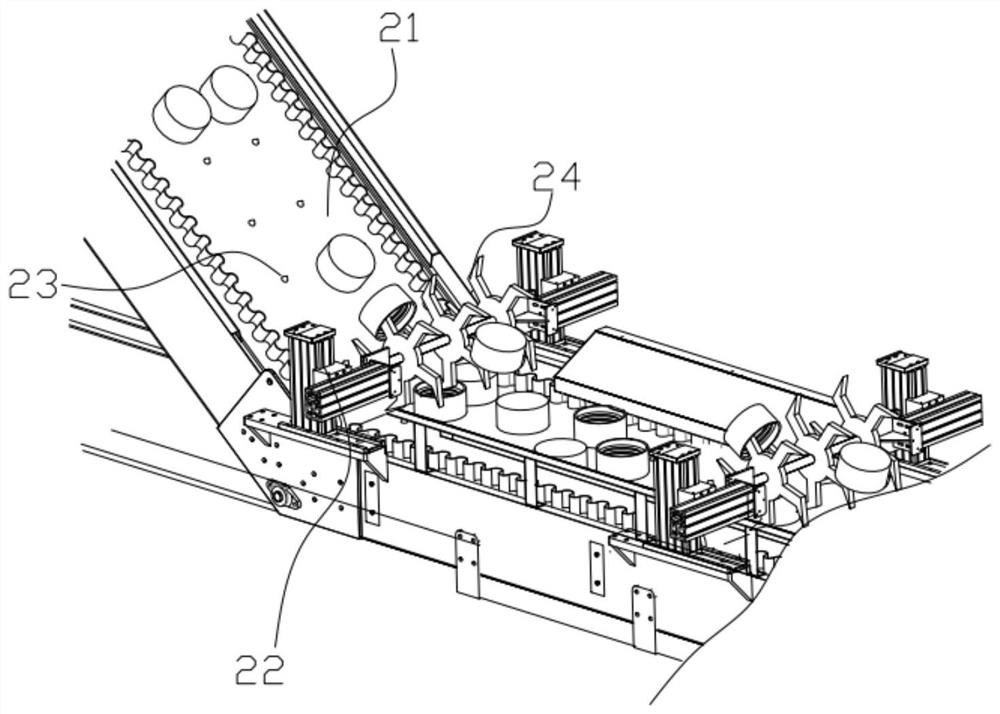

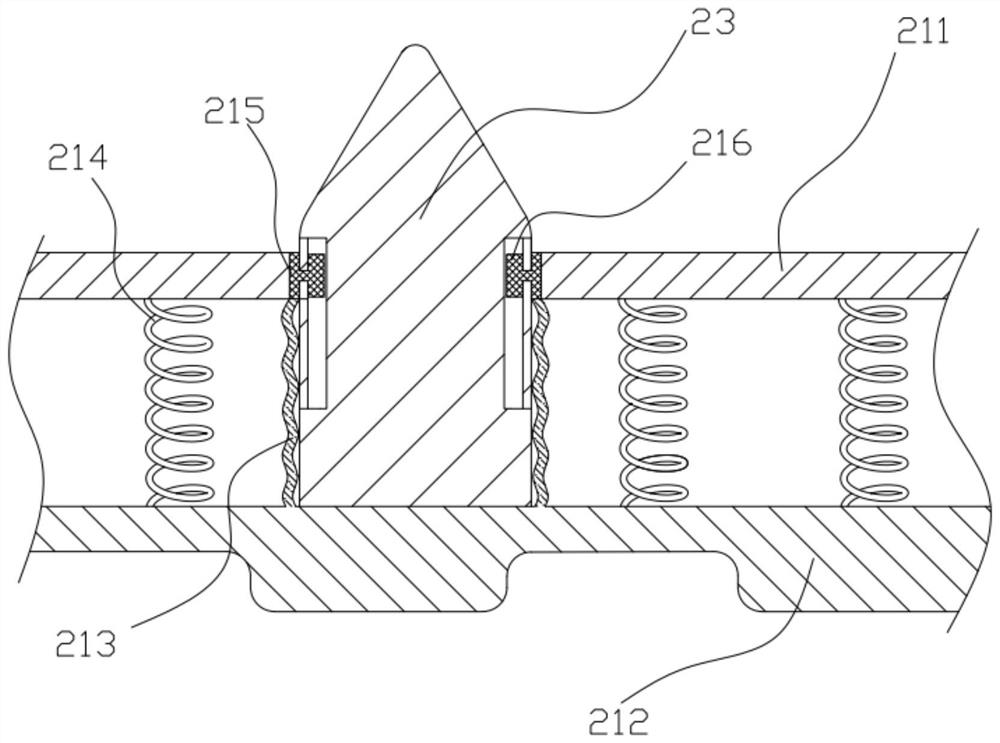

[0036] see figure 1, in the embodiment of the present invention, an automatic cap screwing mechanism for cosmetic bottles, including a transmission device 1, a cap sorting device 2, a clamping device 4 and a cap screwing device 5, wherein the transmission device 1 transmits the cosmetic bottle body in the equipment The cap sorting device 2 can arrange the output bottle caps into a state where the caps are facing downwards, and move the bottle caps to the bottle cap slide 3 connected to the output end, and the bottle cap slide 3 will move the bottle caps The caps are arranged in a row, and are successively hung up and taken away by the cosmetic bottles passing through their ends;

[0037] The clamping device 4 clamps and fixes the cosmetic bottle on the transfer device 1, and moves to just below the capping ring 52 of the capping device 5, and the capping device 5 can tighten the bottle cap on the cosmetic bottle , the rear end of the cap screwing device 4 is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com