Ceramic fiber sound absorption component

A technology of ceramic fiber and ceramic fiber board, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of no fireproof effect, noise-reducing materials are difficult to effectively eliminate wavelength sound waves, etc., and achieve the effect of good strength and rigidity, sufficient toughness and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

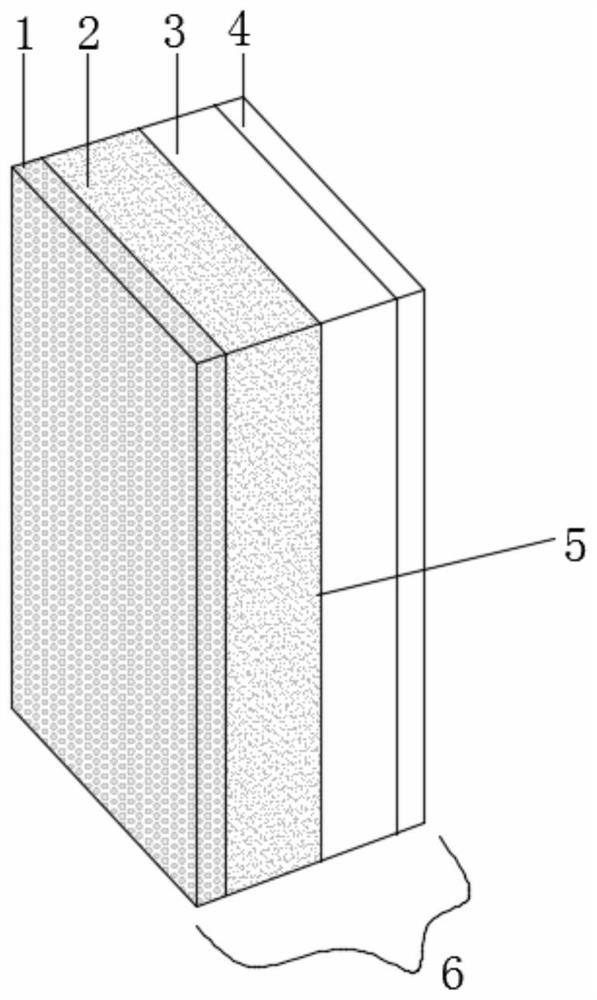

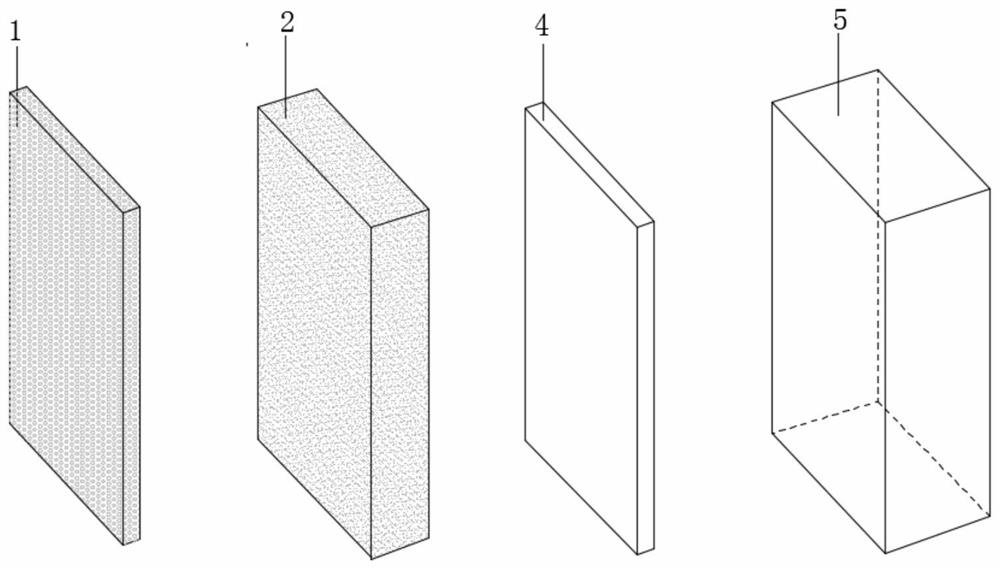

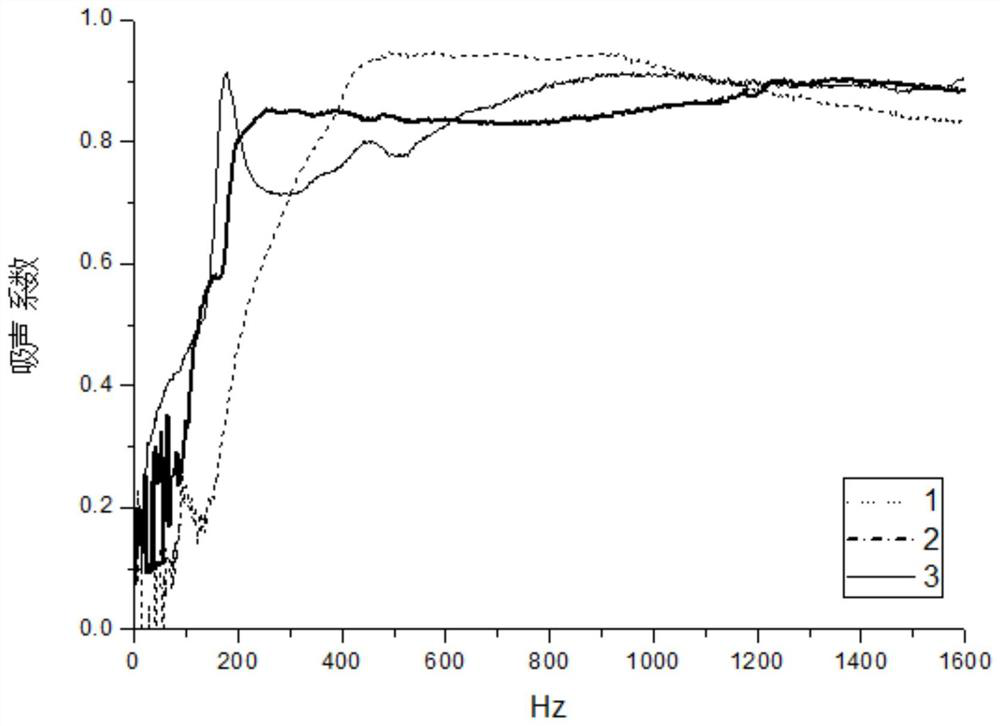

[0031] Example 2, when the overall thickness of the ceramic fiber sound-absorbing member 6 is 81.8mm; the thickness of the micro-perforated plate 1 is 0.8mm, the hole spacing is 6.5mm, and the hole diameter is 0.76mm; the thickness of the ceramic fiber board 2 is 40mm, The bulk density is 96kg / m3; the thickness of the back plate 4 is 1 mm; the thickness of the side plate 5 is 1 mm; when the thickness of the cavity 3 is 40 mm, the sound-absorbing member 6 can make the low-frequency sound absorption coefficient of 100 Hz reach 0.34, and the noise reduction coefficient reached 0.90.

Embodiment 3

[0032] Example 3, when the overall thickness of the ceramic fiber sound-absorbing member 6 is 101.8 mm; the thickness of the micro-perforated plate 1 is 0.8 mm, the hole spacing is 6.5 mm, and the hole diameter is 0.76 mm; the thickness of the ceramic fiber board 2 is 50 mm, The bulk density is 128kg / m3; the thickness of the back plate 4 is 1 mm; the thickness of the side plate 5 is 1 mm; when the thickness of the cavity 3 is 50 mm, the sound-absorbing member 6 can make the low-frequency sound absorption coefficient of 100 Hz reach 0.45, and the noise reduction coefficient reached 0.85.

[0033] Since the present invention can suppress different noise frequency bands by adjusting material parameters and structural parameters, only three embodiments are listed here for introduction. Such as Figure 4 As shown, no matter it is low-frequency sound absorption coefficient, medium-low frequency sound absorption coefficient or medium-frequency sound absorption coefficient, the sound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com