Double-door gap closing device of side by side combination refrigerator

A technology for closing devices and opening doors, which is applied in household refrigeration devices, lighting and heating equipment, household appliances, etc. It can solve the problems of affecting appearance, increasing cost, and increasing power consumption, and achieves high assembly efficiency, increased energy consumption, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

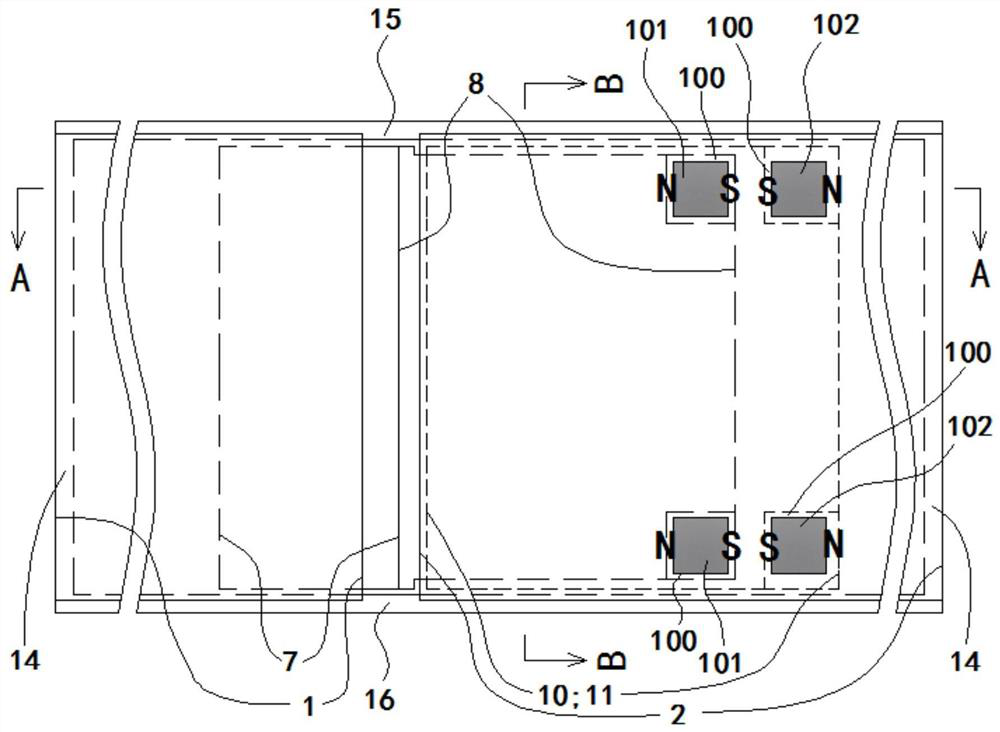

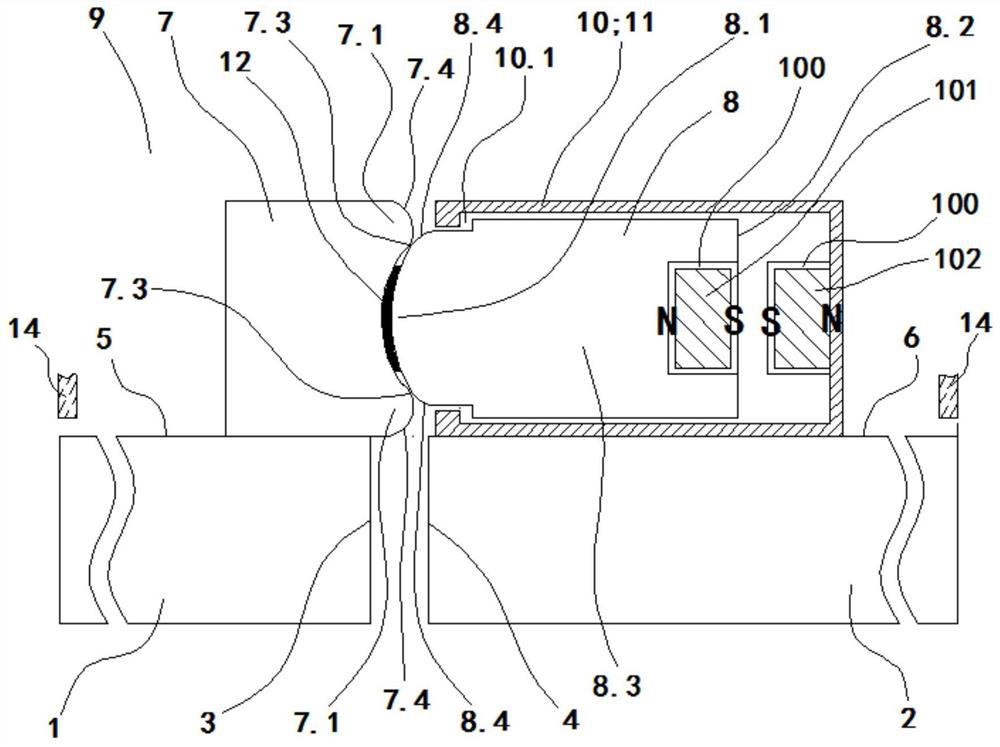

[0067] Example 1, see Figure 1- Figure 4 . On the rear sidewalls 5 and 6 of the inner wall edges 3 and 4 of the two door bodies 1 and 2, a baffle plate 7 and 8 for closing the longitudinal gap of the two doors is longitudinally arranged, and these two baffle plates 7 and 8 are arranged with The opposite surfaces of the respective tops 7.1 and 8.1 are concavo-convex, and the top 8.1 of the convex baffle plate 8 is narrow at the top and nearly wide in the body and / or the top concave area 7.2 of the concave baffle plate 7 at the top The bottom is narrow and the mouth is wide; when the two doors are closed, the top 8.1 of the top of the convex baffle plate 8 is located in the top concave area 7.2 of the top of the concave baffle plate 7;

[0068] Among the two baffle plates 7 and 8, one is a fixed baffle plate 7 with a concave top, and the other is a slidable baffle plate 8 with a convex top that can move laterally; the fixed baffle plate 8 with a concave top is 7 is fixed on t...

Embodiment 2

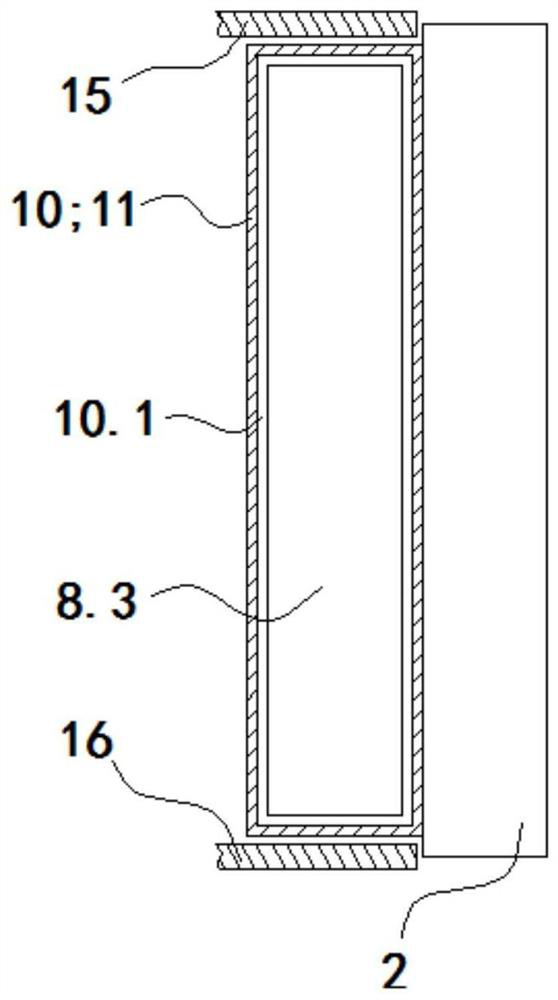

[0074] Example 2, see Figure 5 — Figure 6 , and refer to Figure 1- Figure 4 . The difference between embodiment 2 and embodiment 1 is that the top of the door body 2 is fixed on the convex slidable gap plate 8, and the magnetic internal magnetic force line is parallel to the connecting line between the tail part 8.2 and the top 8.1 of the slidable gap plate. 1. The S-pole magnetic pole surfaces of the two magnets 101 near the top of the slidable gap plate top 8.1, and the opposite magnetic internal magnetic field lines corresponding to each other and fixed on the non-integral magnet 11 with the plate body 10 The S pole magnetic pole face of the magnet 102 that is parallel to the line between the top 8.1 of the top 8.2 of the tail part 8.2 of the slidable gap plate and the inner magnetic force line of the direction of the direction is opposite.

Embodiment 3

[0075] Example 3, see Figure 7 - Figure 9 . On the rear sidewalls 5 and 6 of the inner wall edges 3 and 4 of the two door bodies 1 and 2, a baffle plate 7 and 8 for closing the longitudinal gap of the two doors is longitudinally arranged, and these two baffle plates 7 and 8 are arranged with The opposite surfaces of the respective tops 7.1 and 8.1 are concavo-convex, and the top 8.1 of the convex baffle plate 8 is narrow at the top and nearly wide in the body and / or the top concave area 7.2 of the concave baffle plate 7 at the top The bottom is narrow and the mouth is wide; when the two doors are closed, the top 8.1 of the top of the convex baffle plate 8 is located in the top concave area 7.2 of the top of the concave baffle plate 7;

[0076] Among the two baffle plates 7 and 8, one is a fixed baffle plate 7 with a concave top, and the other is a slidable baffle plate 8 with a convex top that can move laterally; the fixed baffle plate 8 with a concave top is 7 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com