Seamless splicing and paving process of floor cloth for subway vehicle

A seamless splicing and floor cloth technology, which is applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., can solve the problem of aesthetics, insufficient connection, warped edges at the joint between the floor cloth body and the skirting cloth body, etc. problem, to achieve the effect of overcoming slow heat transfer and solving the problem of edge warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

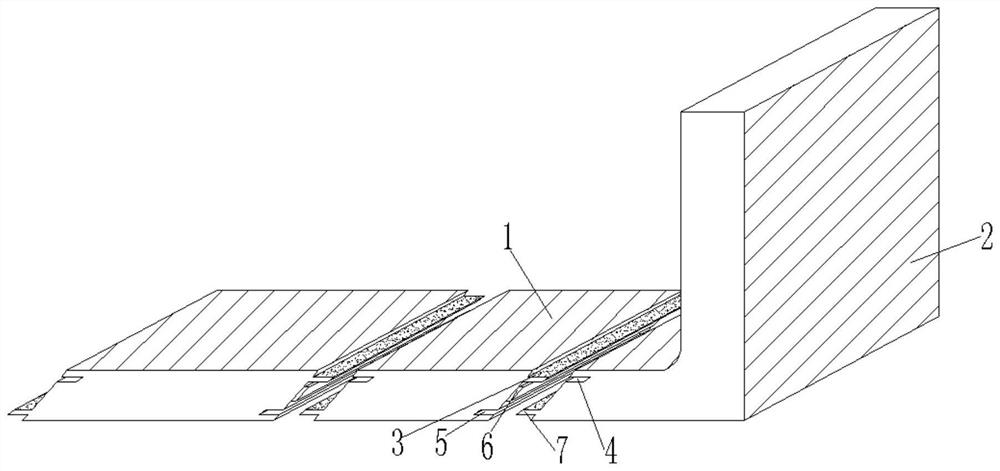

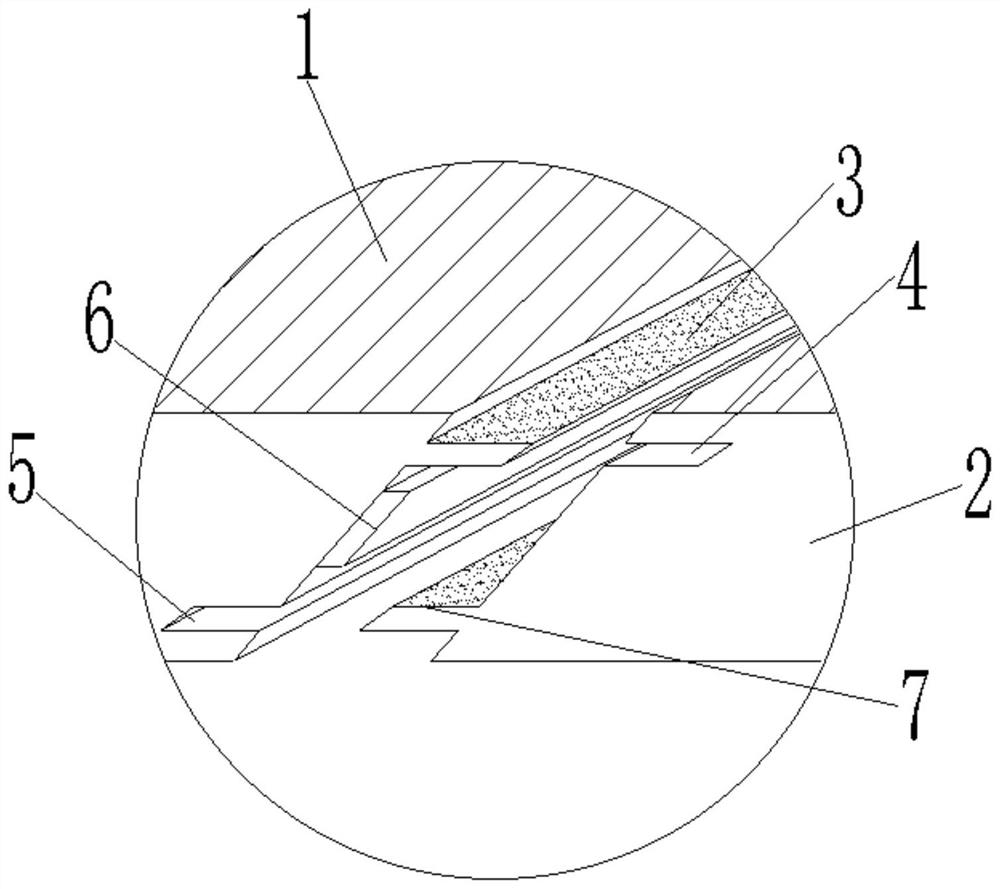

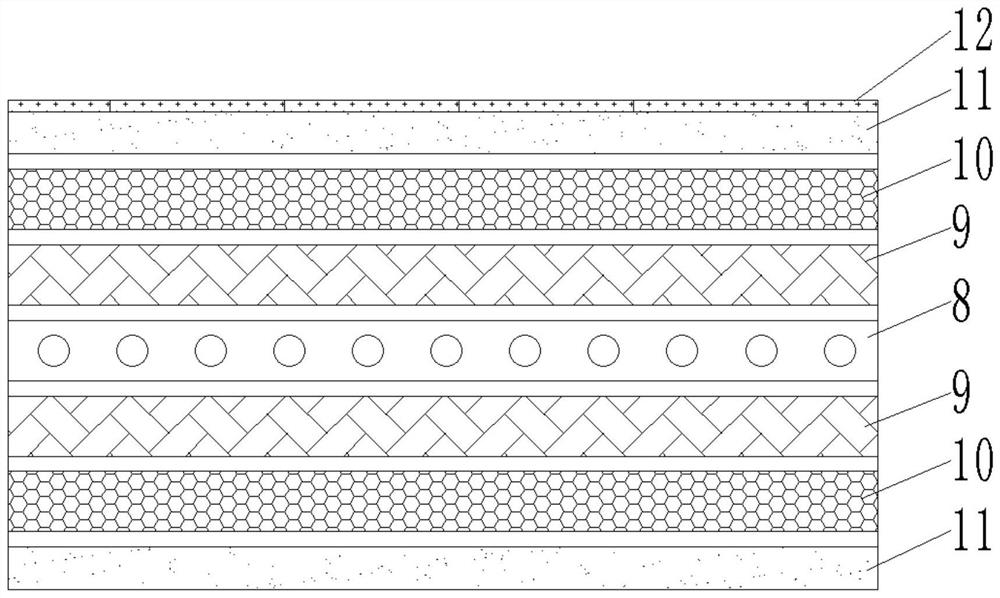

[0051] A seamless splicing and paving process of floor cloth for subway vehicles, comprising a floor cloth body 1 and a skirting cloth body 2, the top of the outer wall on one side of the floor cloth body 1 is welded with a first bump 3, and the floor cloth body 1 is close to the second A side outer wall bottom of a bump 3 is provided with a second card slot 5, and the side outer wall of the skirting cloth body 2 near the first bump 3 is provided with a first card slot 4, and the skirting cloth body 2 is close to the second card slot 4. The bottom of one side of the outer wall of the slot 5 is welded with a second bump 7, the first bump 3 is snapped into the inside of the first slot 4, and the second bump 7 is snapped into the inside of the second slot 5, the floor A rubber hose 6 is provided on the outer wall of the cloth body 1 close to the first bump 3, and the seamless splicing between the floor cloth bodies 1 can be realized by means of clamping, so as to avoid warping of ...

Embodiment 2

[0067] A seamless splicing and paving process of floor cloth for subway vehicles, comprising a floor cloth body 1 and a skirting cloth body 2, the top of the outer wall on one side of the floor cloth body 1 is welded with a first bump 3, and the floor cloth body 1 is close to the second A side outer wall bottom of a bump 3 is provided with a second card slot 5, and the side outer wall of the skirting cloth body 2 near the first bump 3 is provided with a first card slot 4, and the skirting cloth body 2 is close to the second card slot 4. The bottom of one side of the outer wall of the slot 5 is welded with a second bump 7, the first bump 3 is snapped into the inside of the first slot 4, and the second bump 7 is snapped into the inside of the second slot 5, the floor A rubber hose 6 is provided on the outer wall of the cloth body 1 close to the first bump 3, and the seamless splicing between the floor cloth bodies 1 can be realized by means of clamping, so as to avoid warping of ...

Embodiment 3

[0083] A seamless splicing and paving process of floor cloth for subway vehicles, comprising a floor cloth body 1 and a skirting cloth body 2, the top of the outer wall on one side of the floor cloth body 1 is welded with a first bump 3, and the floor cloth body 1 is close to the second A side outer wall bottom of a bump 3 is provided with a second card slot 5, and the side outer wall of the skirting cloth body 2 near the first bump 3 is provided with a first card slot 4, and the skirting cloth body 2 is close to the second card slot 4. The bottom of one side of the outer wall of the slot 5 is welded with a second bump 7, the first bump 3 is snapped into the inside of the first slot 4, and the second bump 7 is snapped into the inside of the second slot 5, the floor A rubber hose 6 is provided on the outer wall of the cloth body 1 close to the first bump 3, and the seamless splicing between the floor cloth bodies 1 can be realized by means of clamping, so as to avoid warping of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com