Anti-shaking pay-off rack used for electric power construction

An electric construction, anti-shake technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of large vibration of cables, inconvenient control of wire rollers, and single structure of pay-off racks, etc. Achieve the effect of reducing large-scale jitter, reducing hard friction, and reducing operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

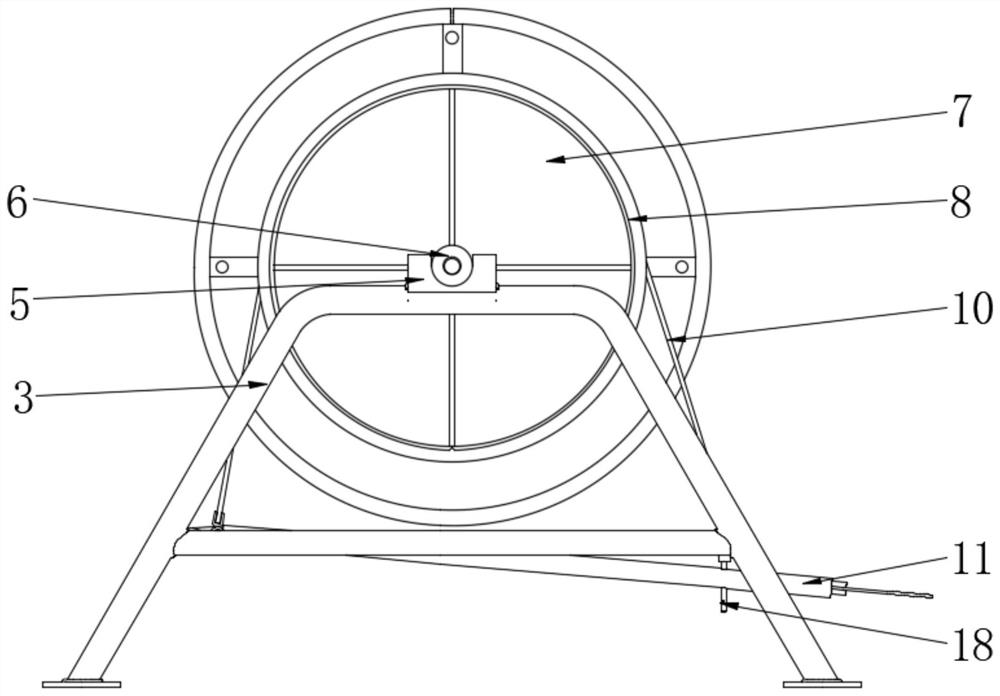

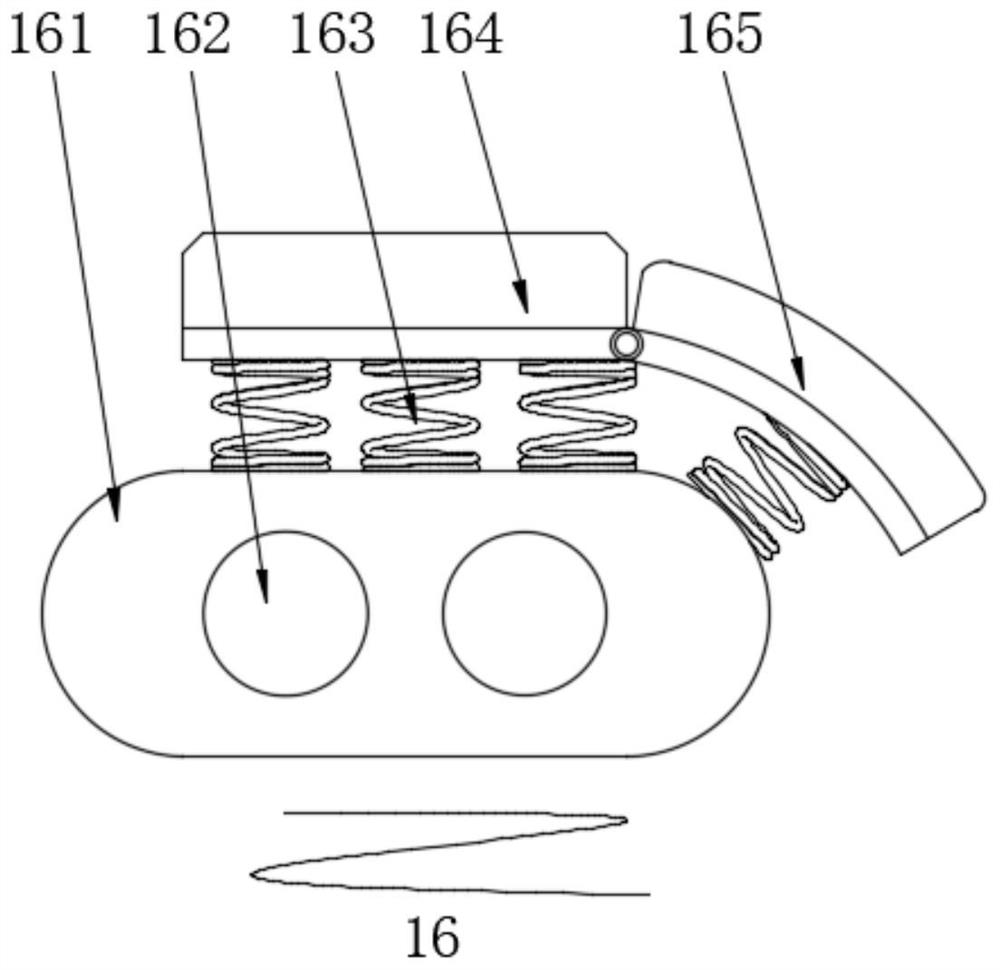

[0019] see Figure 1~3 , in an embodiment of the present invention, an anti-shake type pay-off frame for electric power construction, including a support base 1, a universal wheel 2 is rotatably connected to the bottom of the support base 1, and the top of the support base 1 is located on a A push handle 4 is fixed at the side position, and a support mechanism is fixed on one side of the push handle 4 above the support chassis 1. The support mechanism includes a positioning bracket 3 fixed at a position above the support chassis 1, and the top of the positioning bracket 3 is located in the middle position. Positioning ferrules 5 are symmetrically fixed at the center, and the inner side of the positioning bracket 3 is located at the bottom position to rotate and connect with a pedal rod 11, and the top of the pedal rod 11 is connected with a stop bandage 10, and the stop bandage 10 is made of braided material. , the line roller 7 is socketed with the stop bandage 10 through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com