Sliding rail mechanism and supporting assembly thereof

A technology of slide rail assembly and slide rail, which is applied in the direction of rack/frame structure, electrical equipment structural parts, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

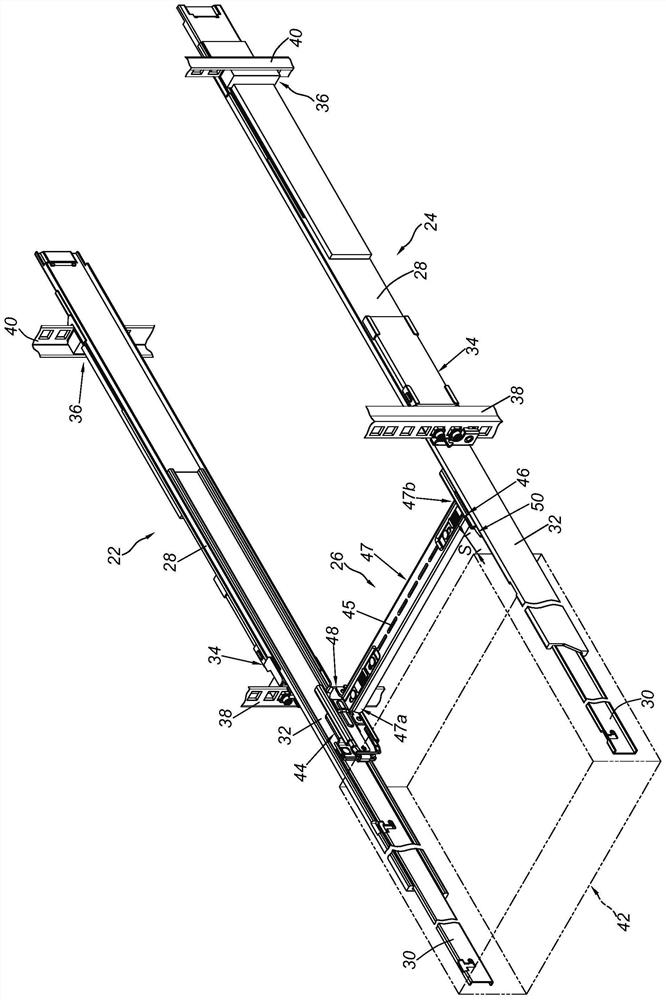

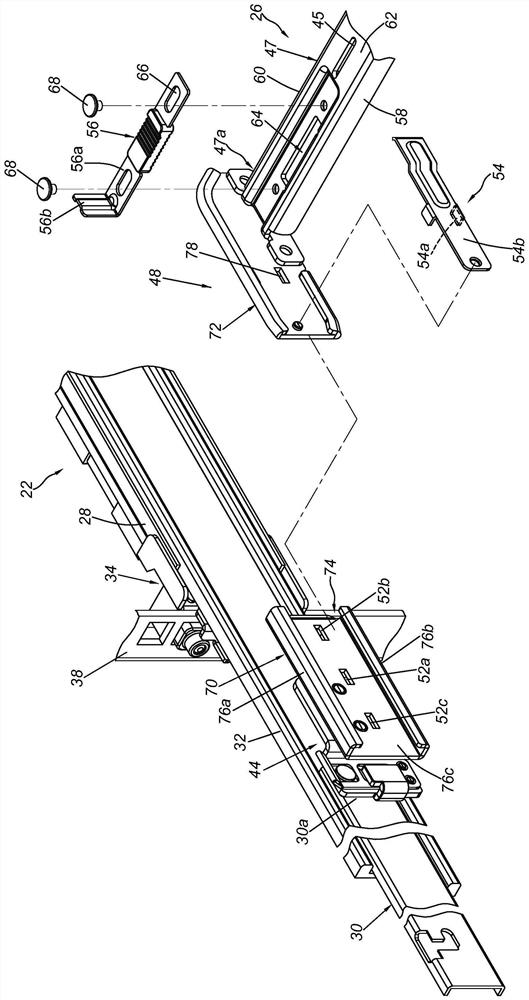

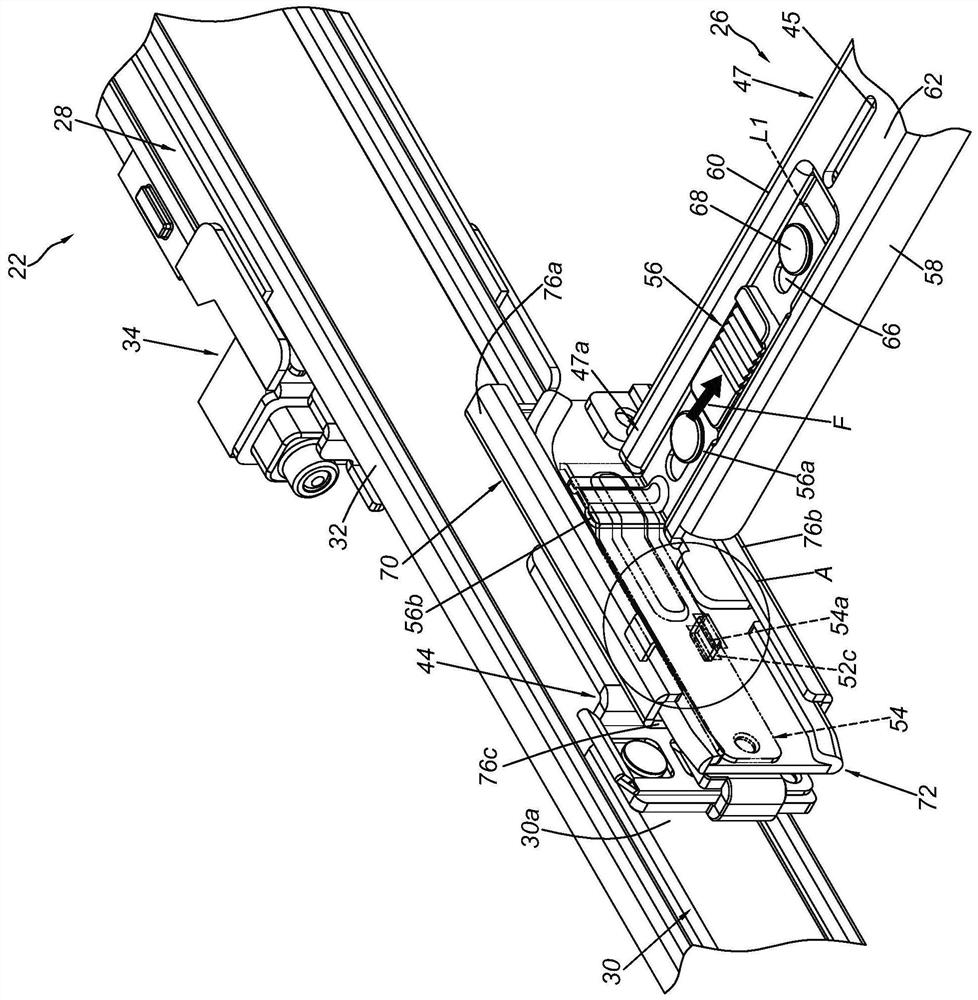

[0042] Such as figure 1 As shown, the slide rail mechanism of the embodiment of the present invention includes a first slide rail assembly 22 , a second slide rail assembly 24 and a support assembly 26 . Both the first slide rail assembly 22 and the second slide rail assembly 24 include a first rail 28 and a second rail 30 . Preferably, a third rail 32 is movably installed between the first rail 28 and the second rail 30 to extend the displacement stroke of the second rail 30 relative to the first rail 28 . Here, the first rail 28 , the second rail 30 and the third rail 32 are respectively an outer rail (fixed rail), an inner rail and a middle rail as examples. Wherein, the front portion and the rear portion of the first rail 28 can be installed on a first machine column 38 and a second machine column 40 of a frame through a first bracket device 34 and a second bracket device 36 respectively. On the other hand, the second rail 30 can be displaced longitudinally relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com