Intelligent replenishment system

A replenishment system and intelligent technology, applied in the field of logistics management, can solve problems such as spending a lot of time and energy, spending a lot of time and money, and wasting enterprise costs, so as to reduce labor intensity and costs, enhance competitiveness, and improve accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

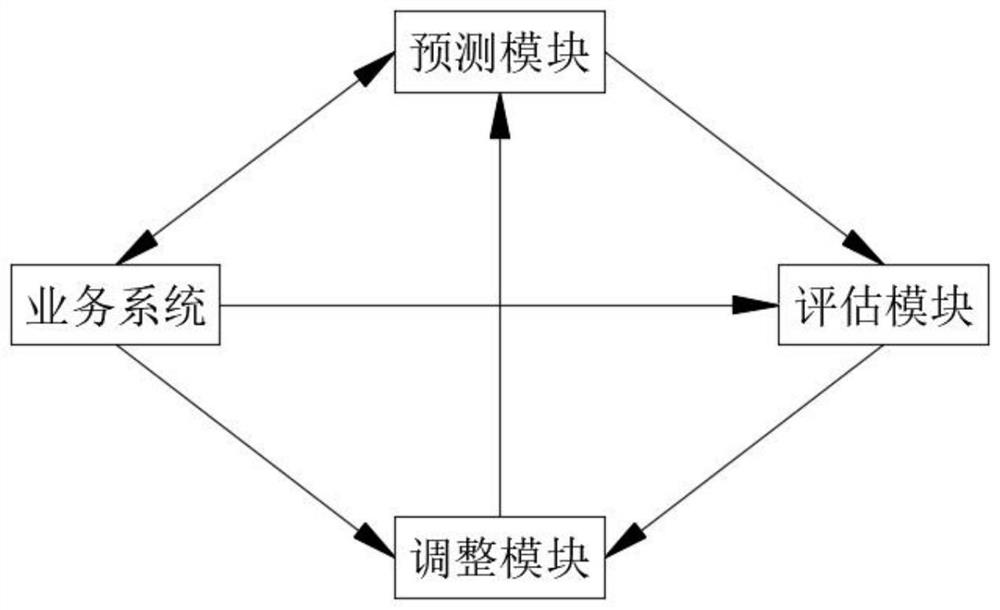

[0045] Such as figure 1 An intelligent replenishment system is shown, including a business module, a forecast module, an adjustment module and an evaluation module.

[0046] A business module for placing an order; and the business module is an OP system;

[0047] The forecasting module is used for product demand forecasting to obtain a demand forecasting scheme; wherein, the execution steps of the forecasting module are:

[0048] S1. Carry out sales forecast; the specific steps of the step S1 are as follows:

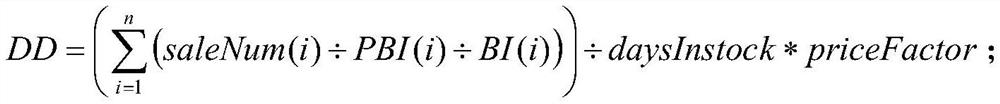

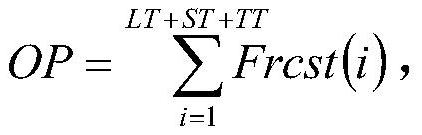

[0049] (1) Use the formula to predict the sales of the day i days later,

[0050] Frcst(i)=DD*BI(i)*PBI(i),

[0051] Among them, i=1,2,3...n, n represents a natural number; PBI(i) is the event explosion factor, specifically, if there is an event tomorrow and the predicted sales volume is twice the usual, then PBI(i)=2 ;

[0052] BI(i) is the seasonal factor, the ratio obtained by calculating the average sales volume of the year and the weekly sales volume of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com