Wiring module

A technology of incoming line and busbar clips, which is applied in the direction of fully enclosed busbar devices, busbar/line layout, etc., can solve the problems of cumbersome assembly process, time-consuming and laborious, etc., and achieve the effect of simple assembly process, reducing labor cost and expanding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

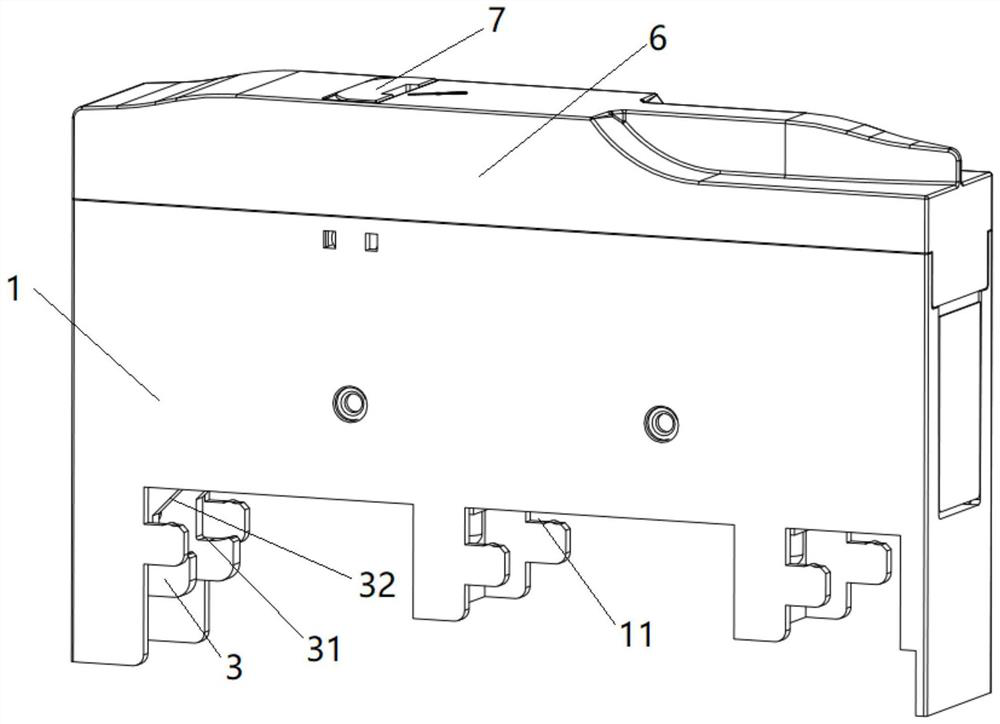

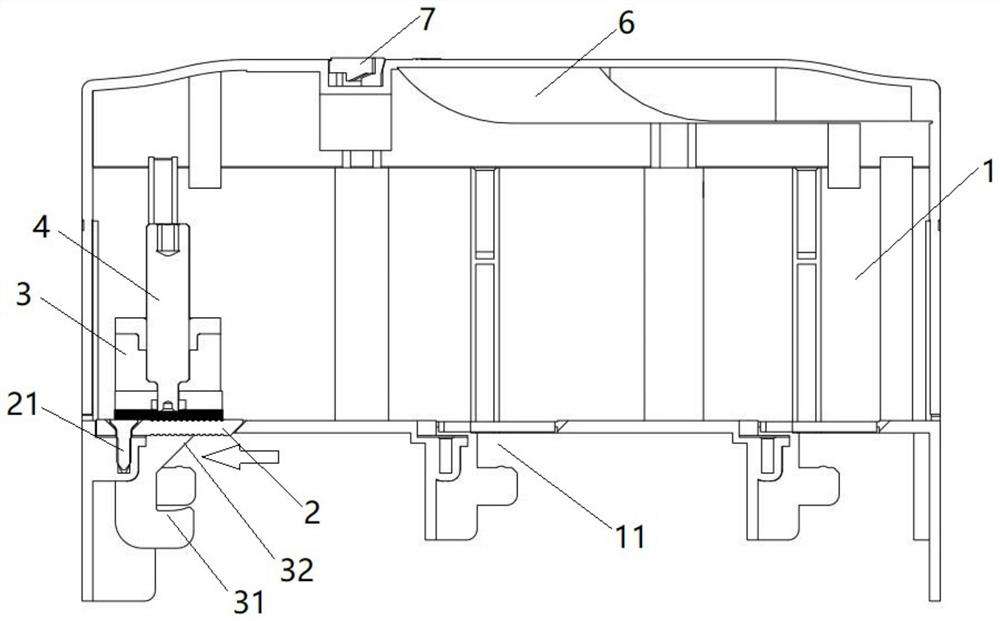

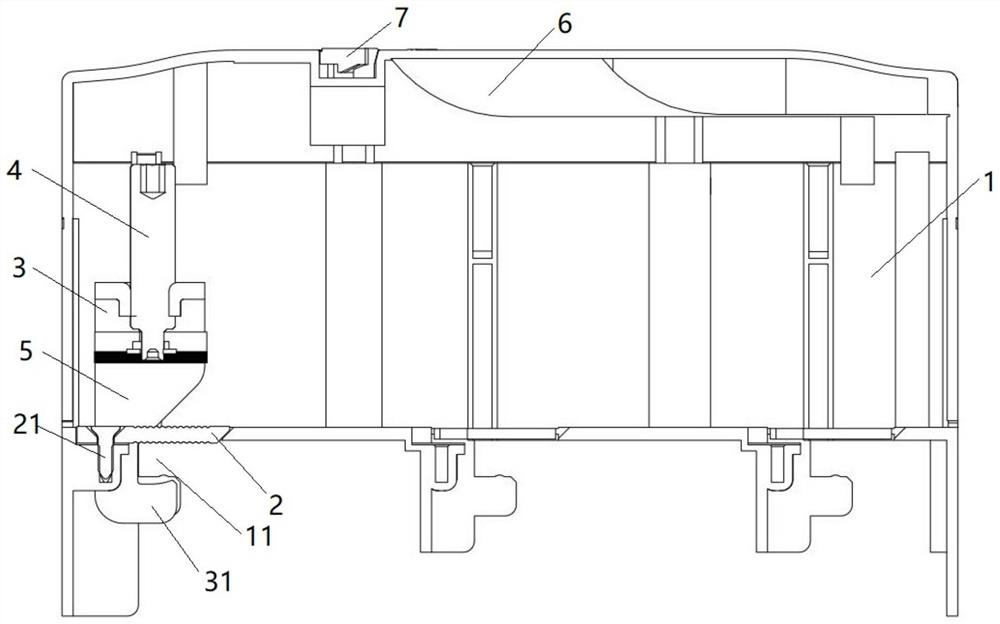

[0044] This embodiment provides a wiring module, such as figure 1 with 2 As shown, it includes base 1, contact piece 2, bus bar clamp 3, cover plate 6 and locking piece 7.

[0045] Base 1, such as figure 1 , 4 , 5, the bottom of which is provided with a slot 11 for the insertion of the incoming busbar, and an installation step 15 located below the slot 11. The installation step is provided with a protrusion for preventing the incoming busbar from detaching after it is inserted. 16, two slide grooves 12 are arranged on the two inner sides opposite to each other on the base 1, and the slide grooves 12 extend along the vertical direction, and two second insertion slots are arranged on the inner side of the base 1. hole 13, and two limiting holes 14 are formed on the inner wall of the second insertion hole 13.

[0046] Contact 2, such as figure 2 As shown, it is fixed on the base 1 by screws 21, and is located in the middle of the clamping cavity of the busbar clamp 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com