Split buckle type grounding wire

A technology of split card and grounding wire, which is applied in the direction of connection, conductive connection, and electrical component connection. It can solve the problems of easy falling, entanglement of wire rods, and entanglement of wires, etc., and achieves simple and fast storage, convenient hooking, and storage convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

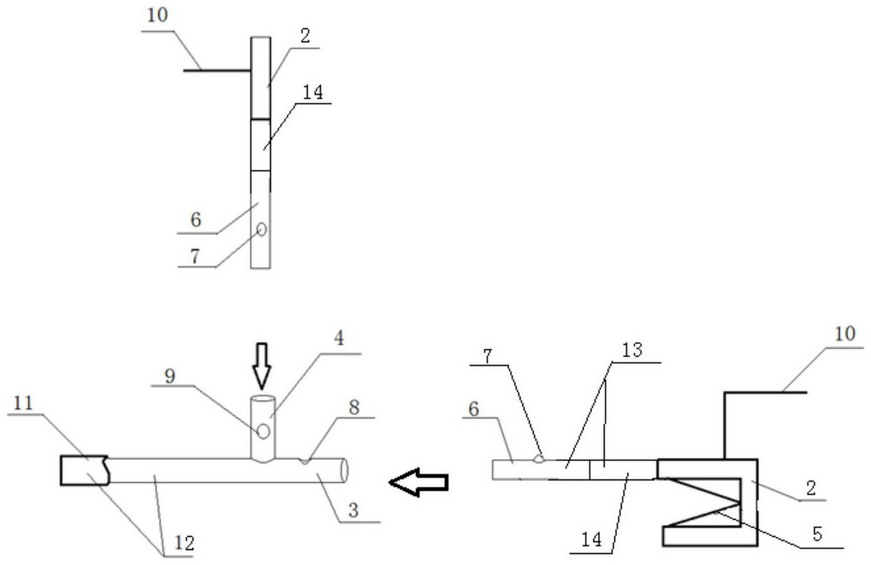

[0033] Such as figure 1 As shown, a split buckle-type grounding wire includes: a split buckle-type insulation operating rod 1, and a ground wire head 2;

[0034] The split insulated operating rod 1 is composed of an operating rod support part 12 and an operating rod connecting part 13;

[0035] The top of the operating rod support part 12 is provided with a horizontal snap connector A3 along the horizontal direction, and a vertical snap connector B4 along the vertical direction; one end of the operating rod connecting part 13 is fastened to the horizontal snap connector A3 or the vertical The buckle connector B4, the other end of the operating rod connecting part 13 is connected to the grounding wire head 2; the grounding copper wire 10 is connected to the grounding wire head 2;

[0036] The operating rod connecting part 13 includes a reserved length 14 and a buckle connector C6, one end of the buckle connector C6 is buckled with the horizontal buckle connector A3 or the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com