Project progress auxiliary robot applied to construction supervision and supervision detection method

A technology of project progress and detection methods, applied in the direction of unmanned aerial vehicles, instruments, aircraft, etc., can solve the problems of cumbersome data sorting, affecting the progress of multiple project acceptance, and illegally knowing the progress of construction sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

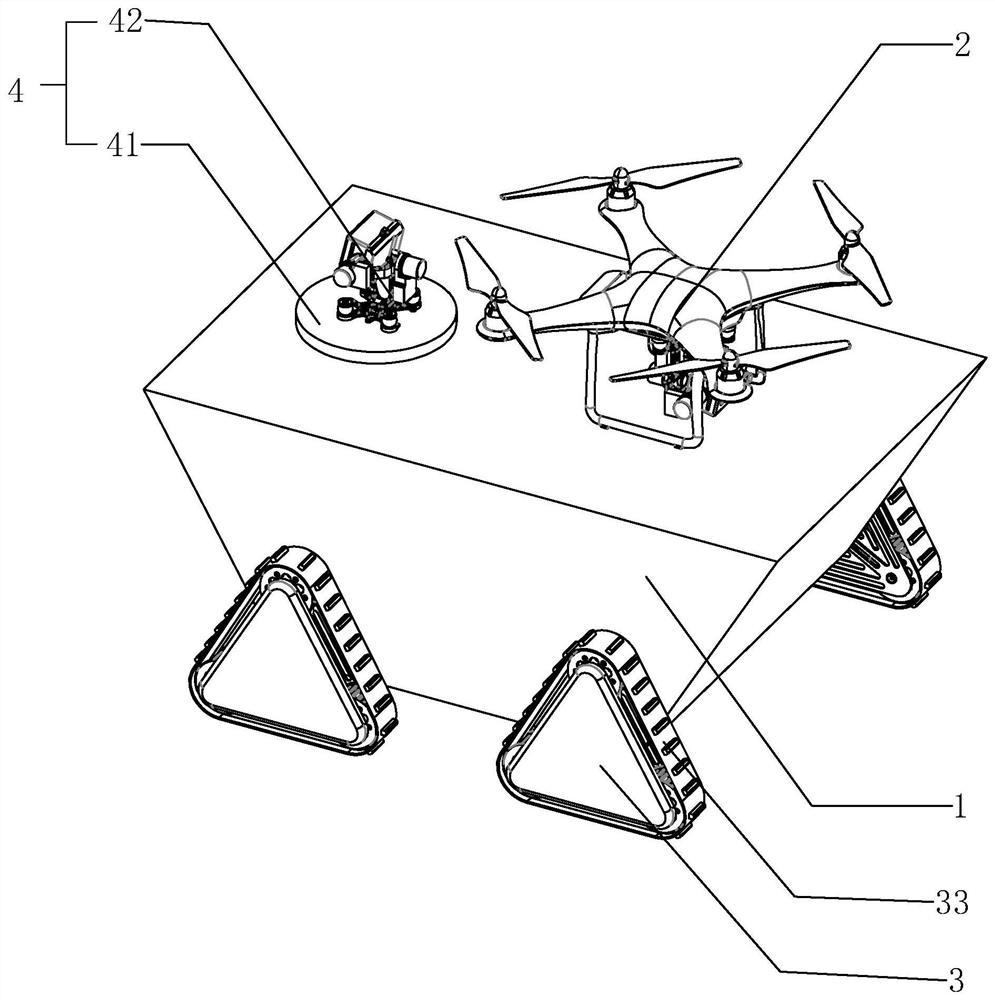

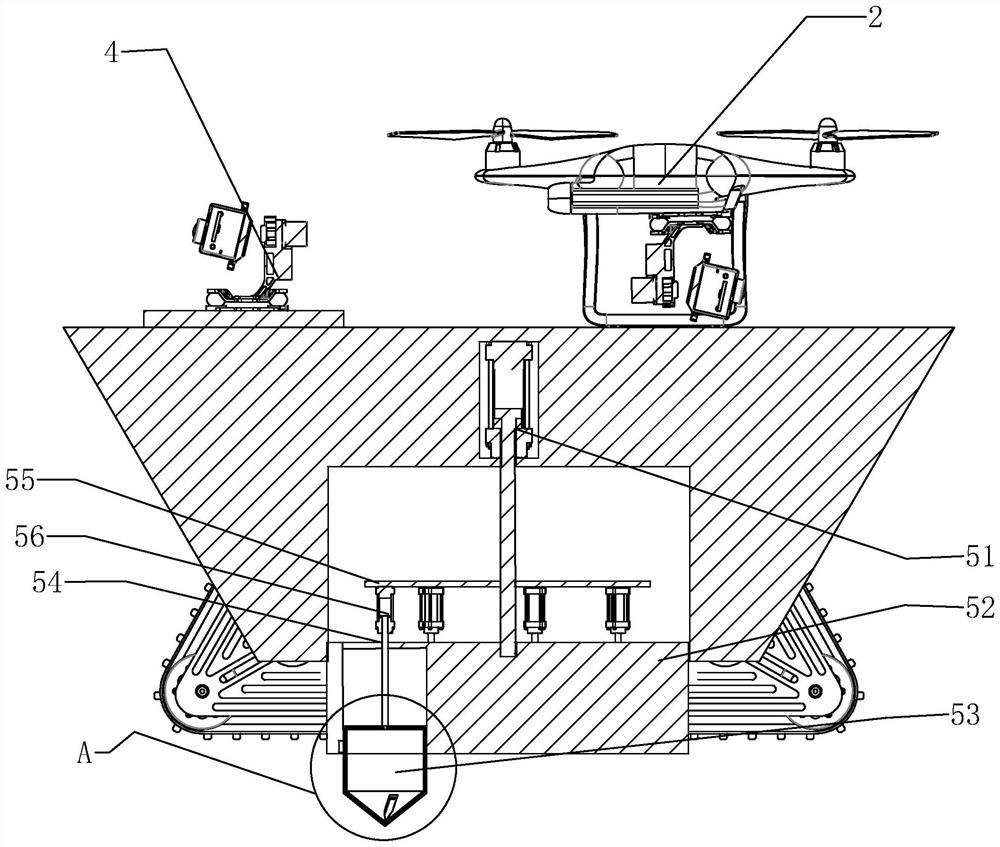

[0056] refer to figure 1 and figure 2 , is a project progress auxiliary robot applied to construction supervision disclosed by the present invention, including a body 1, a detachable unmanned aerial vehicle 2 located on the body 1, and a rolling member 3 rotatably connected to the side wall of the body 1. The rolling member 3 includes a fixed On the sun gear 31 of the power input, three planetary gears 32 are evenly meshed on the sun gear 31, and the crawler belt 33 is connected to the planetary gear 32, and the sun gear 31 is connected to a driving component, and the driving component is a motor; the body 1 is provided with a camera device 4 , the camera device 4 includes a control pan-tilt 41 fixed on the body 1, the control pan-tilt 41 is provided with a camera 42, the camera 42 is provided with a level sensor, and the level sensor can keep the camera 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com