Step-type anchoring robot of fully mechanized excavation face

A working face, step-by-step technology, applied in the installation of bolts, mine roof supports, support devices, etc., can solve the problems of bulky excavation components and anchoring equipment, affecting the speed of equipment excavation and anchoring, and high manual labor intensity. , to achieve the effect of high anchoring efficiency, strong work adaptability and flexible turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

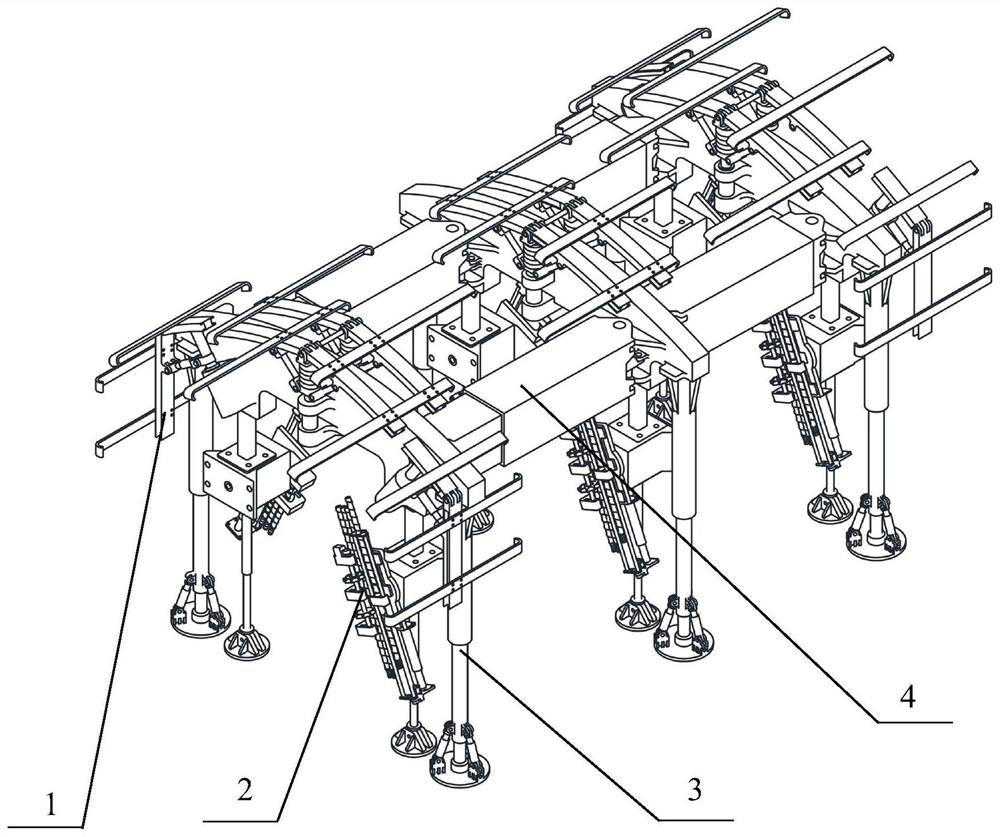

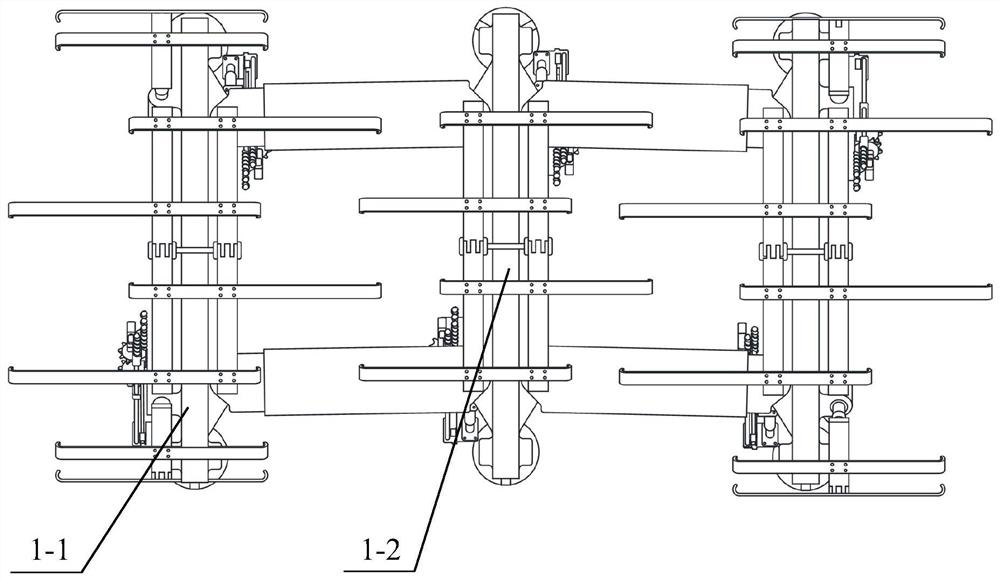

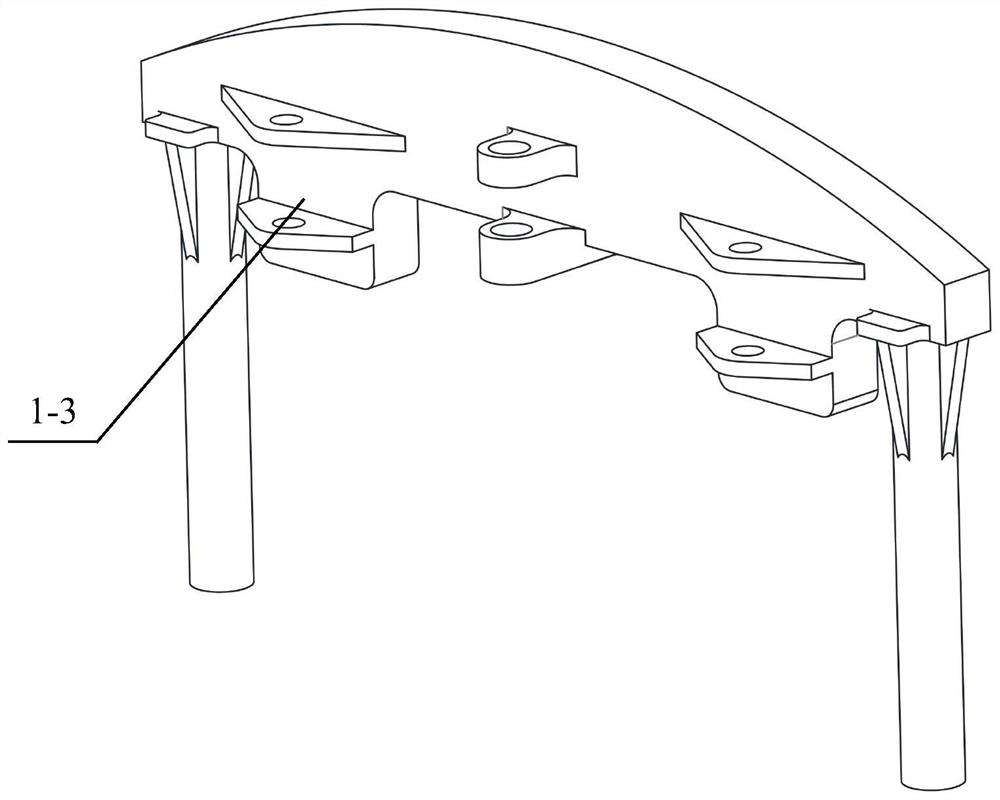

[0055] see figure 1 , a walking-type anchor support robot for fully mechanized excavation working faces, comprising a netting system 1, an anchoring system 2, a ground support system 3, a power and turning system 4; the netting system 1 is installed on the ground support system 3 above; the anchor system 2 is installed under the main girder 1-3 and the intermediate girder 1-4 in the grid system 1 by screws; the ground support system 3 is installed in the grid system 1 Below the main girder 1-3 and the middle main girder 1-4; the two ends of the power and tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com