Wind wheel installation platform

A technology for installing platforms and wind wheels, which is applied to workbenches, manufacturing tools, etc., can solve the problems of large occupied area, low efficiency, and high assembly cost, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

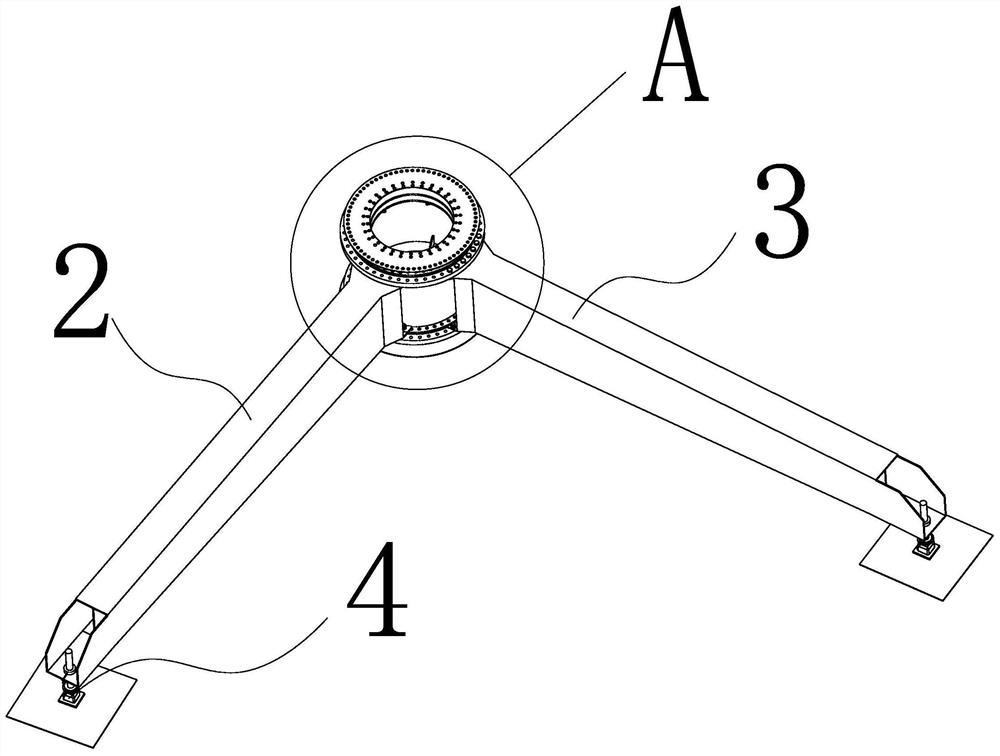

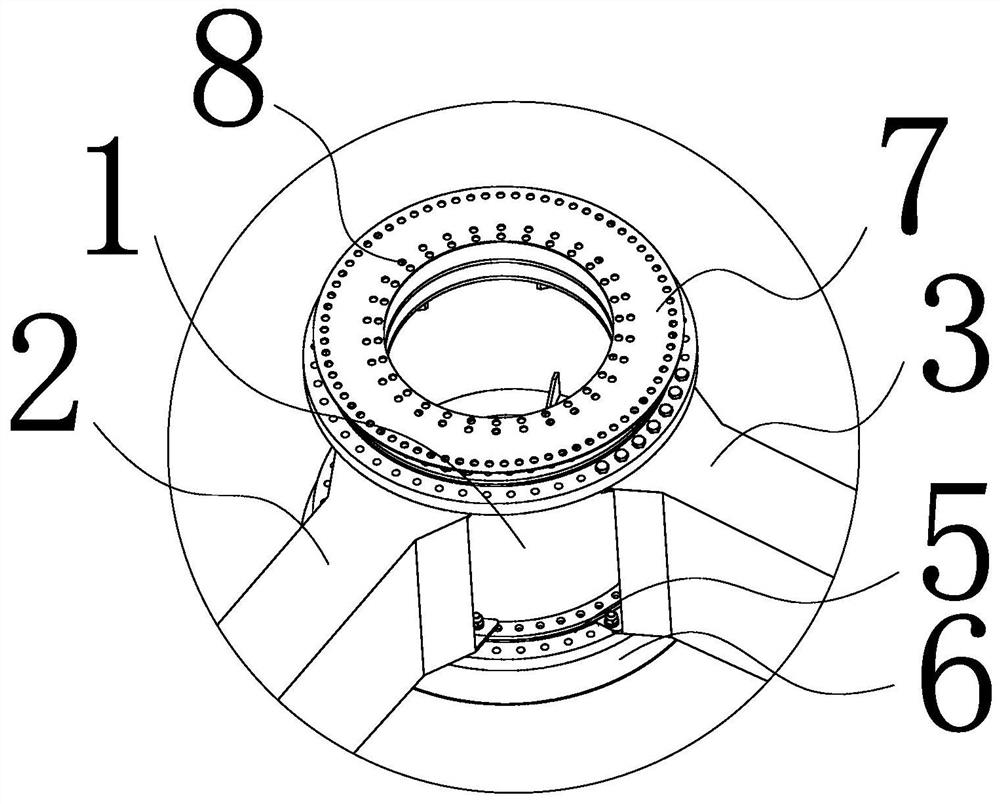

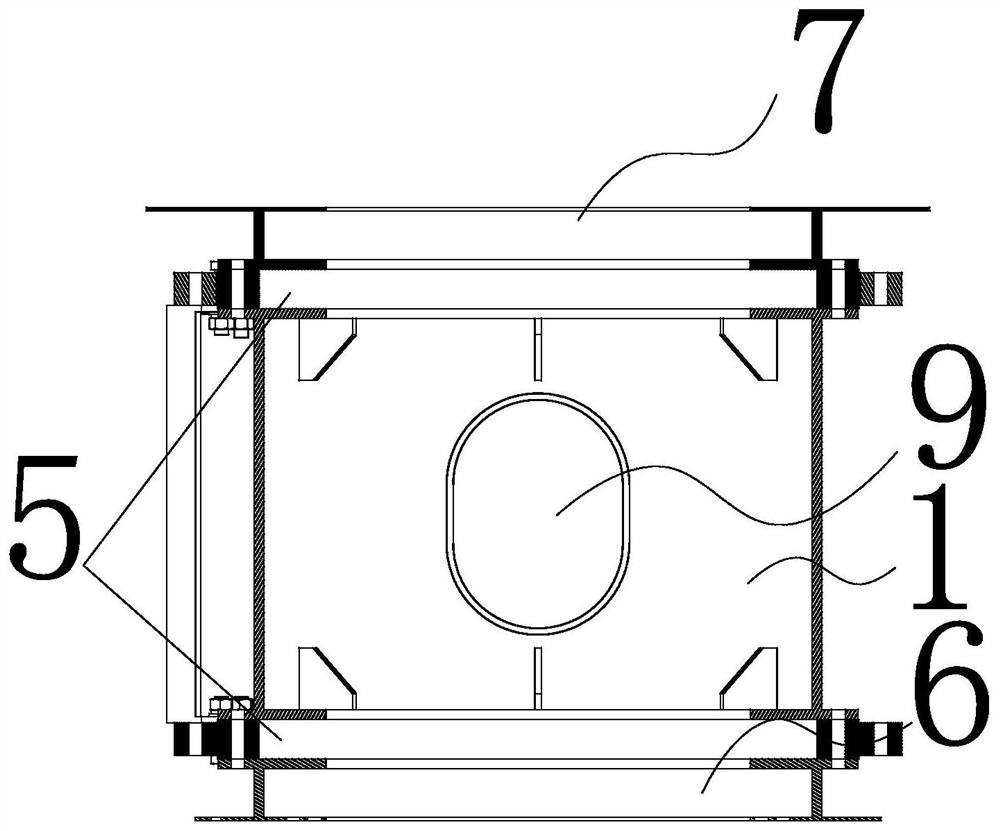

[0023] like figure 1 , figure 2 and image 3 As shown, a wind wheel installation platform of the present invention includes a circular support tube 1 vertically placed on the ground, with two manholes 9 on the side wall of the support tube 1, and the two ends of the support tube 1 are respectively The hub support 7 and the base 6 are coaxially installed by bolts. On the outer end surface of the hub support 7, there are several hub positioning holes 8 that match with the mounting holes on the hub of the wind wheel along the circumferential direction. On the support tube 1 The rotating bearing 5 is coaxially clamped and installed between the end surface and the hub support 7, and the rotating bearing 5 is also coaxially clamped and installed between the lower end surface and the base 6. The rolling bearing 5 is supported between the hub support 7 and the end surface of the support cylinder 1 and the base. 6 and the end surface of the support cylinder 1, the inner side end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com