A cutting board auxiliary oiling device

A cutting board and bottom board technology, which is applied in the field of auxiliary oiling devices for cutting boards, can solve the problems of cumbersome manual operation, uneven application, inconvenient oiling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

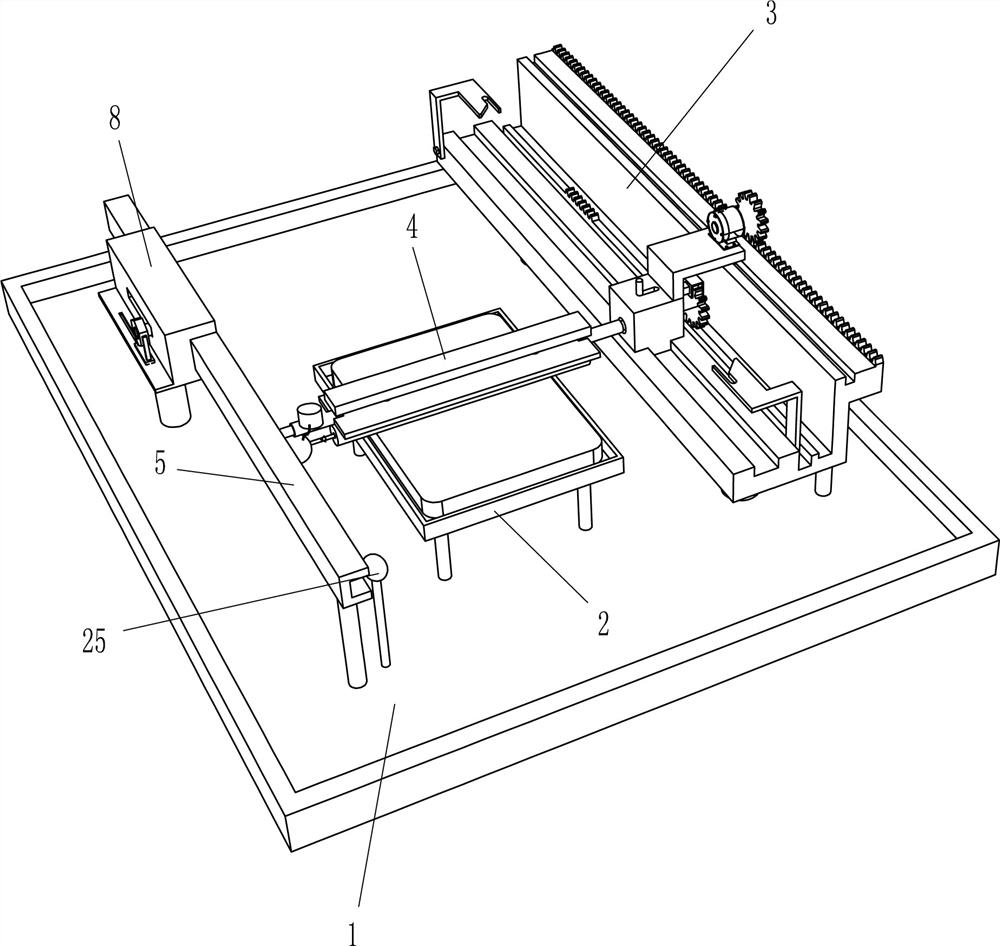

[0023] A cutting board auxiliary oiling device, such as Figure 1-3 As shown, it includes a base plate 1, a placement frame 2, a translation mechanism 3, and a smearing mechanism 4. The center of the top of the base plate 1 is provided with a placement frame 2, the right side of the top of the base plate 1 is provided with a translation mechanism 3, and the left side of the translation mechanism 3 is provided with an alignment Applicator mechanism for oil on the board4.

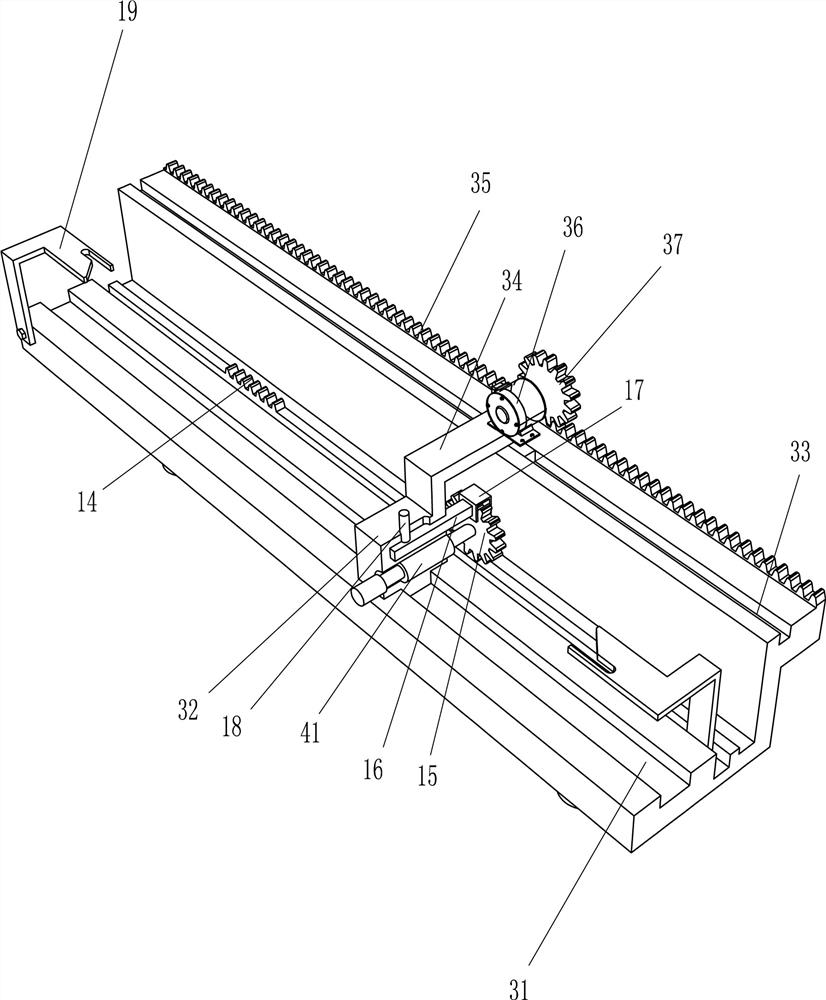

[0024] Translation mechanism 3 includes L-shaped slide plate 31, first slide block 32, L-shaped slide block 34, long rack 35, servo motor 36 and first gear 37, bottom plate 1 top right side is provided with L-shaped slide plate 31, L-shaped Sliding type is provided with the first slide block 32 on the slide plate 31, and upper chute 33 is arranged on the right side of the L-shaped slide plate 31 top, and an L-shaped slide block 34 is slidably matched in the upper chute 33, and the L-shaped slide block 34 is c...

Embodiment 2

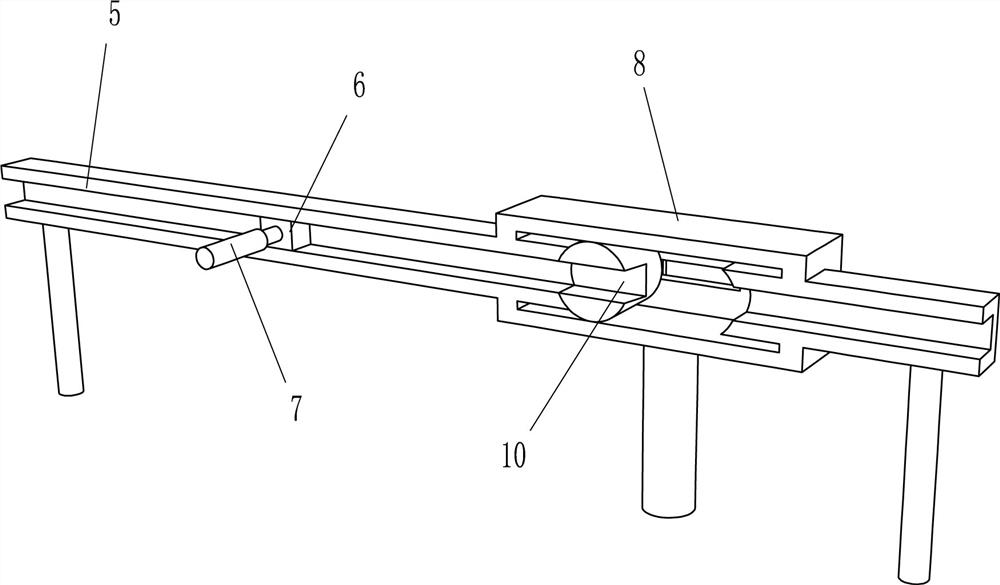

[0028] On the basis of Example 1, such as Figure 1-5 As shown, it also includes a side slide rail 5, a second slider 6, a telescopic shaft 7, a connecting groove block 8, a second rotating shaft 9, an insert 10, a third slider 11, a hexagon 12, an elastic sheet 13, Short rack 14, second gear 15, square slide bar 16, top block 17, top column 18 and guide block 19, side slide rail 5 is arranged on the left side of bottom plate 1 top, second slide block 6 slides with side slide rail 5 Cooperate, the right side of the second slider 6 is provided with a telescopic shaft 7, the right end of the telescopic shaft 7 is fixedly connected with the left side of the middle plate 42, the rear side of the side slide rail 5 is embedded with a connecting groove block 8, and the left side wall of the connecting groove block 8 A slot is opened, and a second rotating shaft 9 is arranged in the gap in the slot of the connecting slot block 8, and the right end of the second rotating shaft 9 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com