Cyclone back pressure online adjustment device

A technology of adjusting device and back pressure device, which is applied in the direction of swirl device and the device whose axial direction of swirl can be reversed, etc., can solve the problems of blocked discharge port, troublesome operation, blockage of heavy product discharge port, etc., and achieves Guaranteed sorting effect, convenient operation, and improved smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

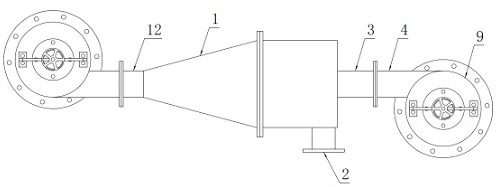

[0014] The invention provides an online cyclone back pressure adjustment device, which can continuously adjust the back pressure of the cyclone on-line according to the actual production demand without shutting down the cyclone, which solves the problem of material During the sorting process, there are technical problems that the internal flow field is unstable due to the defects of the cyclone itself and the back pressure device at the discharge port cannot be adjusted online. The invention is simple to operate, can be adjusted according to actual products and sorting conditions, and has strong applicability.

[0015] see figure 1 , the present invention mainly includes a back pressure device feeding pipe 4, an adjustment screw 5, an adjustment hand wheel 6, an adjustment bracket 7, a pressure regulating column 8, a cylinder 9 and a tapered funnel 10.

[0016] In practical application, the cyclone back pressure online adjustment device is directly connected in series behind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com