Multi-filtration sewage treatment efficient sedimentation tank

A high-efficiency sedimentation tank and sewage treatment technology, which can be used in sedimentation separation, sedimentation tank, and the feeding/discharging device of sedimentation tank, etc., which can solve the problems of slow drainage, slow sedimentation, and long sedimentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

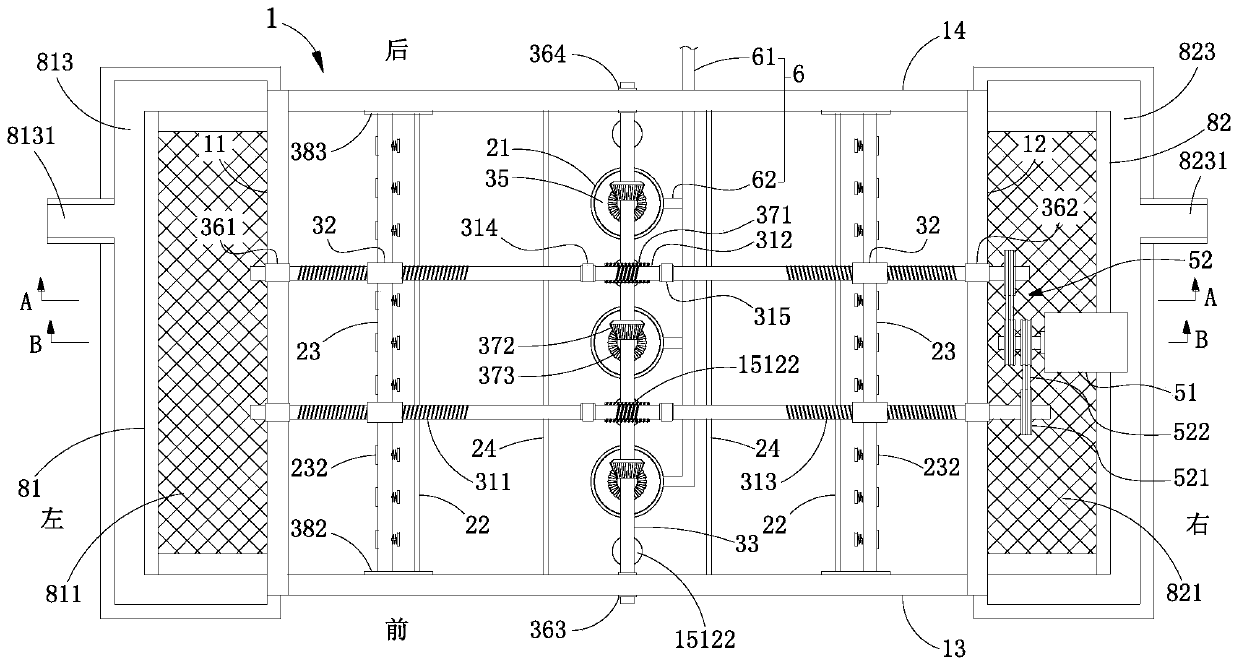

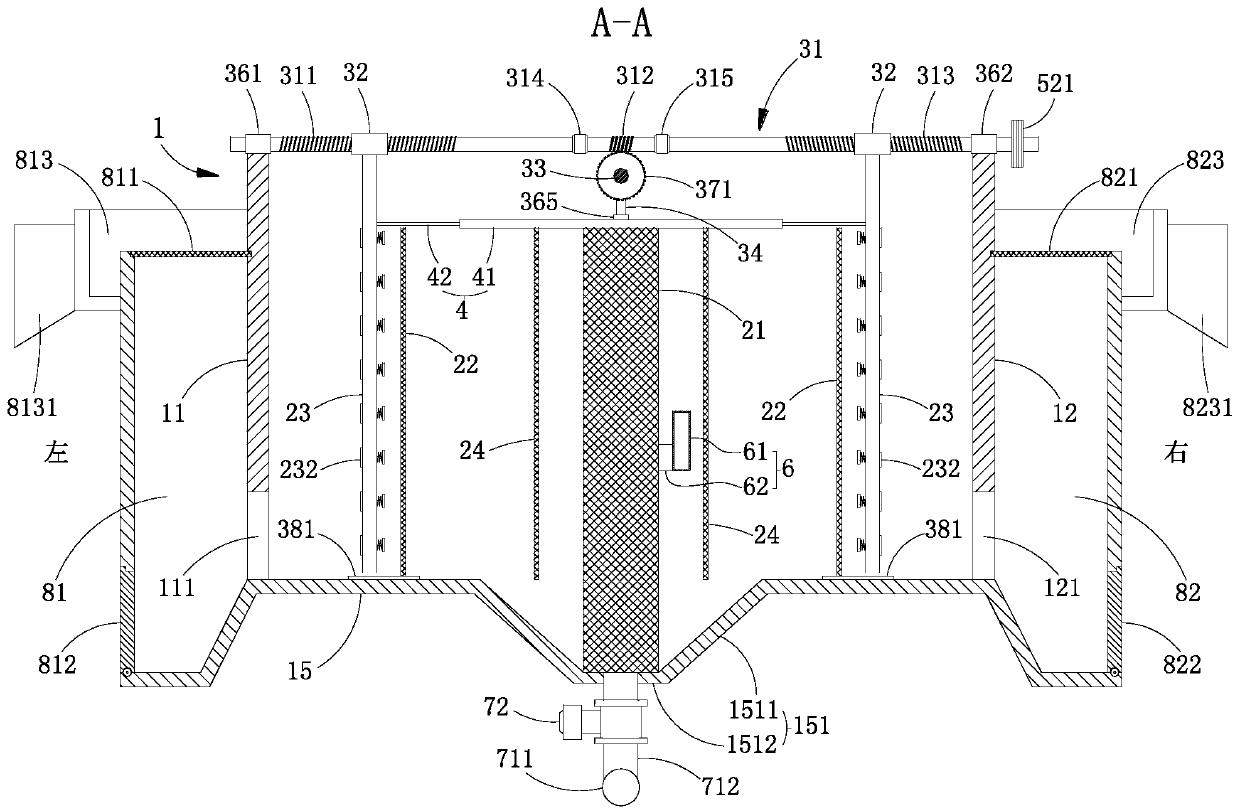

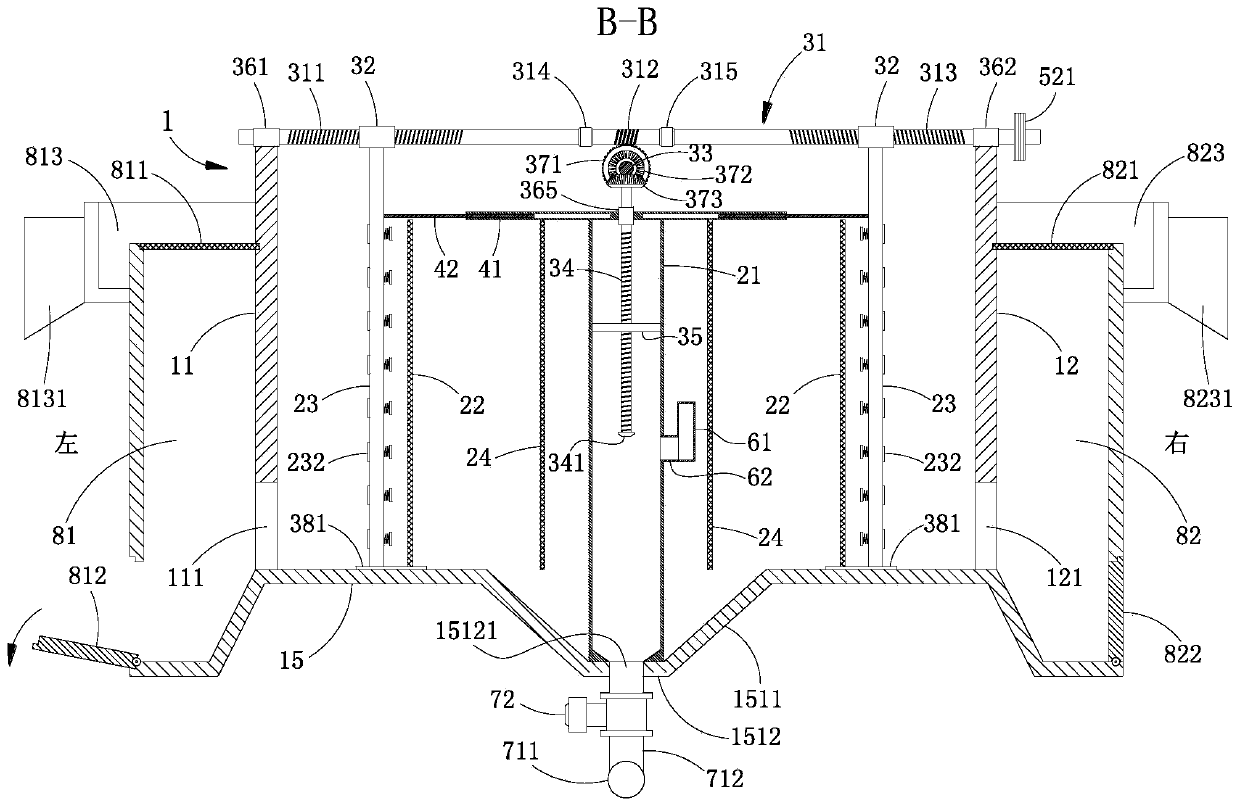

[0061] see Figure 1-Figure 11 As shown, the present invention provides a high-efficiency sedimentation tank for multiple filtration sewage treatment, which includes a tank body 1, a sludge filter part, a filter pressure part, a tank top sealing plate 4, a motor 5, a water inlet pipeline 6, a sewage discharge assembly and drainage pool.

[0062] see Figure 1-Figure 3 , the pool body 1 is formed by four facades 11, 12, 13, 14 enclosing a bottom surface 15; wherein, the bottom of the left facade 11 is provided with a left drain 111, and the bottom of the right facade 12 is provided with There is a right drain 121, and the middle part of the bottom surface 15 has a sinking tank 151 for collecting sludge. The sinking tank 151 is composed of two downward slopes 1511 and a horizontal tank bottom 151...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com