Package chip clamp capable of avoiding blockage

A technology for loading chips and fixtures, which is applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., and can solve the problems of easily damaged leads, low effect, and heavy workload of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

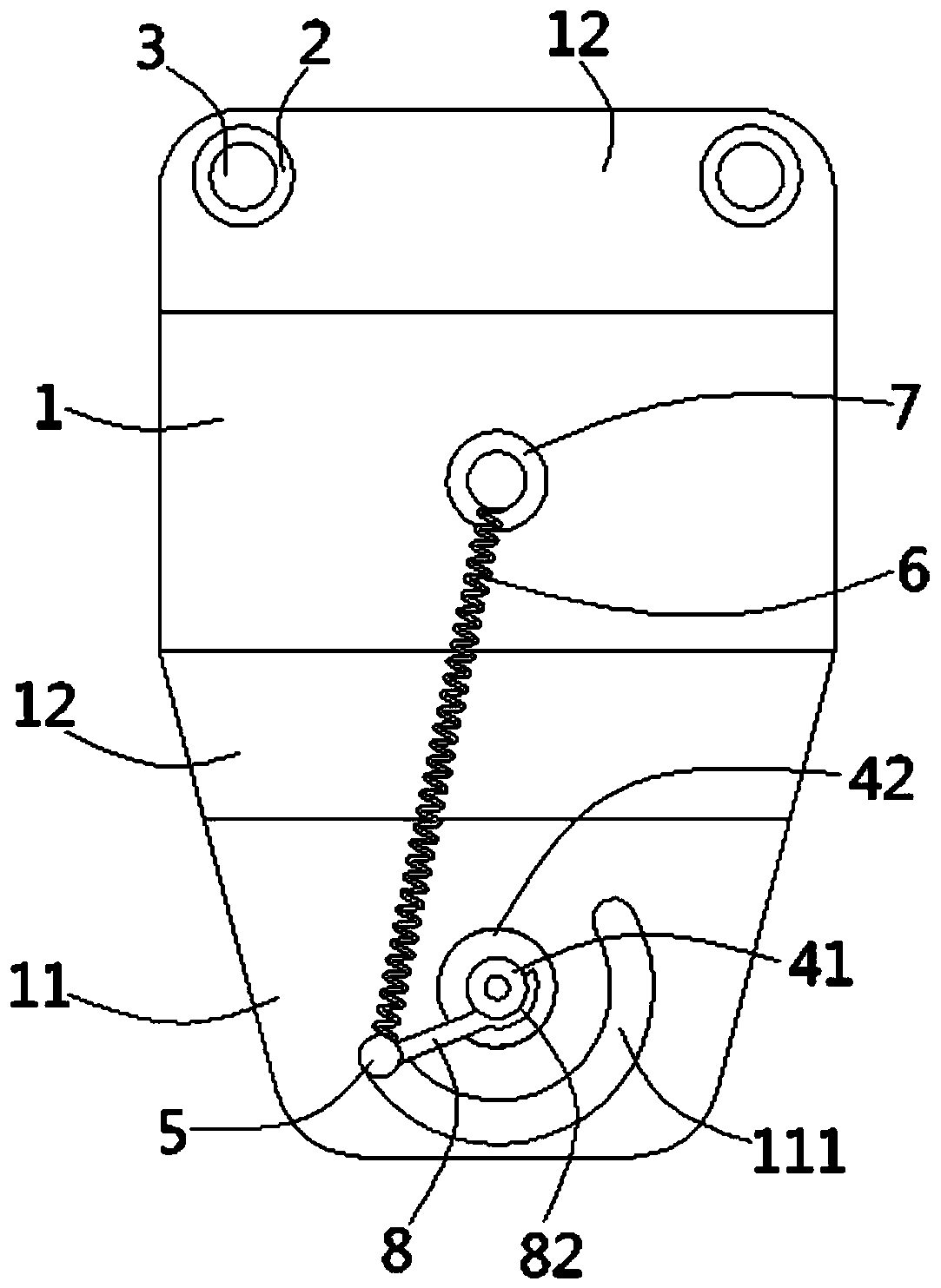

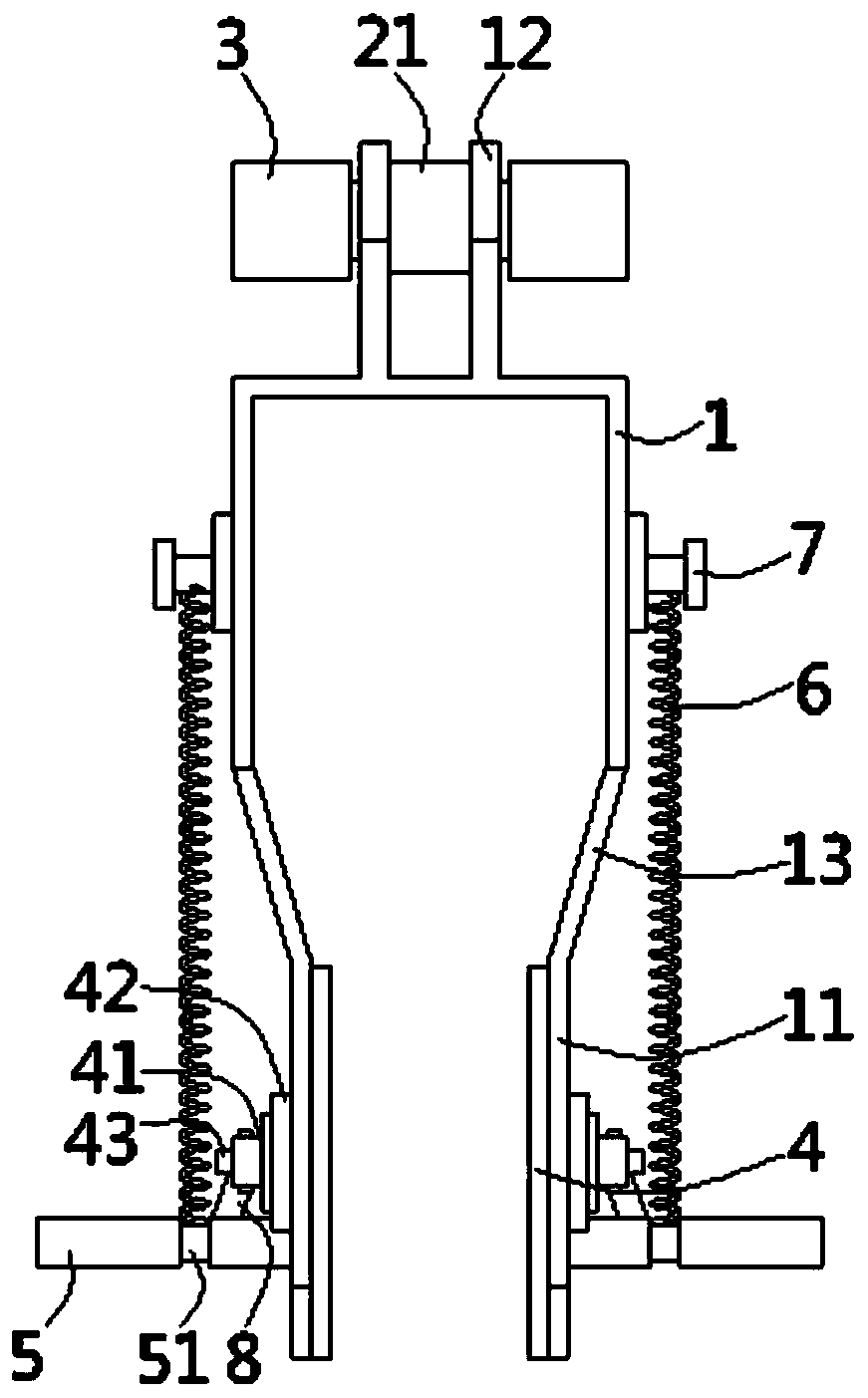

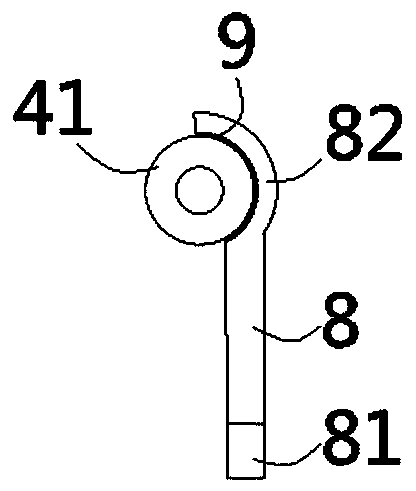

[0021] The following content reference Figure 1 to Figure 4 .

[0022] A jig for packaged chips that avoids being blocked according to the present invention includes a "匚"-shaped top plate 1 and elastic splints 11 bent and formed on both sides of the top plate, and a pair of vertical connecting plates are formed on the upper end of the top plate 12. A number of connecting shafts 2 are plugged on the connecting plate, and the two ends of the connecting shaft protrude from the connecting plate sleeve to fix the roller 3, and the middle part of the connecting shaft is clamped with an arc-shaped limit ring 21, the limit The two ends of the ring lean against a pair of connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com