Optical synchronous measurement method for combustion flow field of scramjet engine

A technology of scramjet and synchronous measurement, which is used in internal combustion engine testing, measurement devices, aerodynamic tests, etc., can solve the problems of inability to perform supplementary verification, inaccurate flow information acquisition, etc., to improve interactivity and eliminate image distortion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

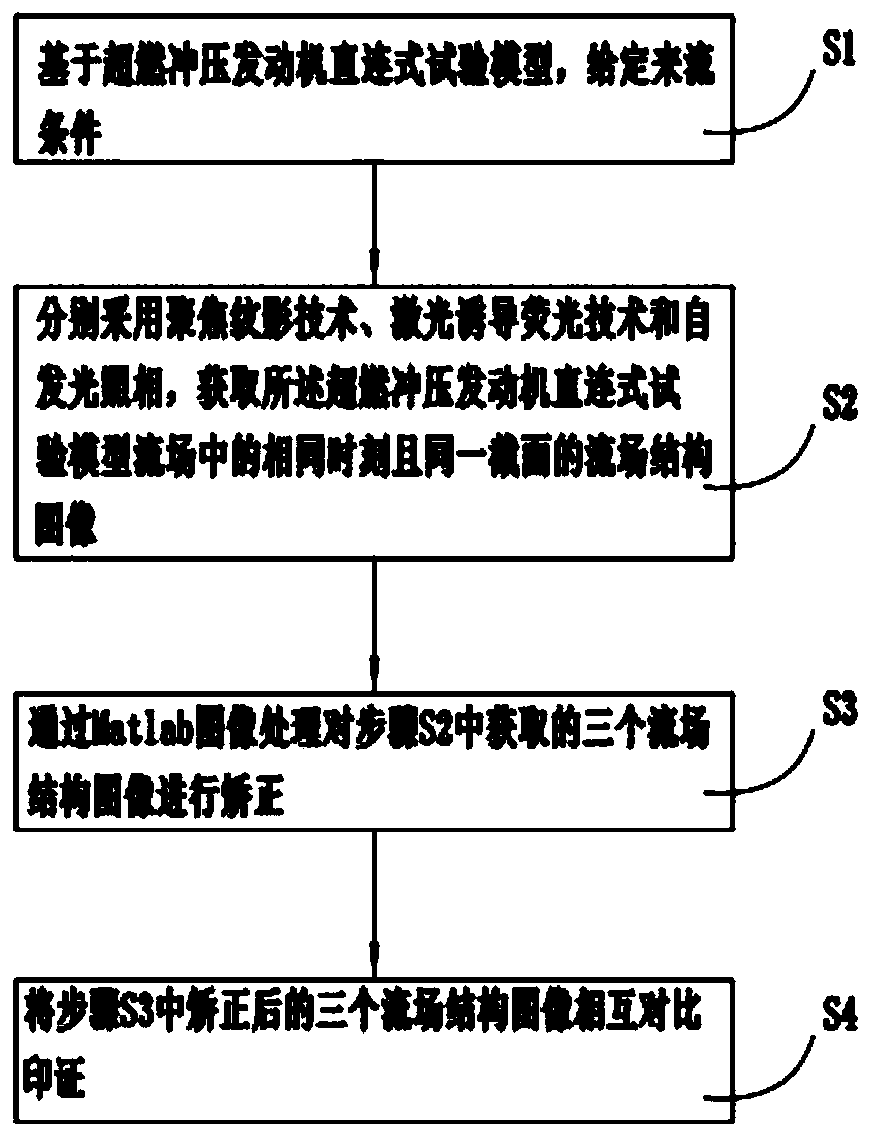

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

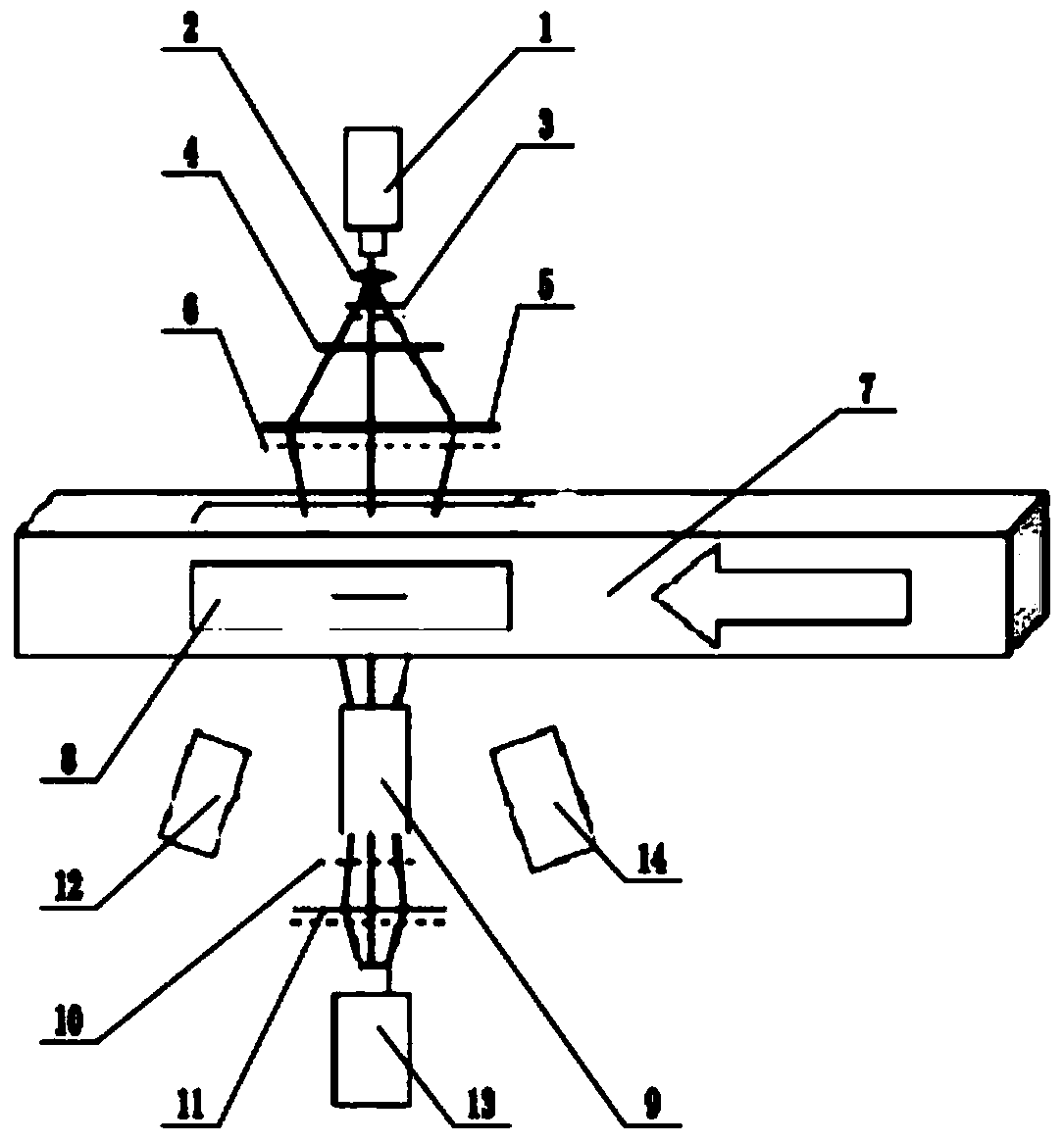

[0028] The reference signs in the drawings of the description include: continuous laser 1, short-focus lens 2, hologram 3, ground glass 4, Fresnel lens 5, source grid 6, scramjet direct-connected test model 7, quartz glass Observation window 8, imaging lens 9, knife-edge grid 10, imaging screen 11, ICCD camera 12, first high-speed camera 13, second high-speed camera 14.

[0029] A scramjet combustion flow field optical synchronous measurement method, which adopts the optical path settings such as figure 2 As shown, the optical path components mainly include: continuous laser 1, short-focus lens 2, hologram 3, ground glass 4, Fresnel lens 5, source grid 6, pulse laser, optical path shaping system, imaging lens 9, knife-edge grid 10, ICCD camera 12 , first high-speed camera 13 and second high-speed camera 14 . The sheet light in the figure is generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com