Turbine vacuum system leakage detection comprehensive test device and method

A vacuum system and comprehensive testing technology, applied in the field of steam turbines, can solve the problems of destructive detection, unsatisfactory leak detection effect, low sensitivity, etc., to improve accuracy and reliability, ensure consistency and accuracy, and helium diffusion fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

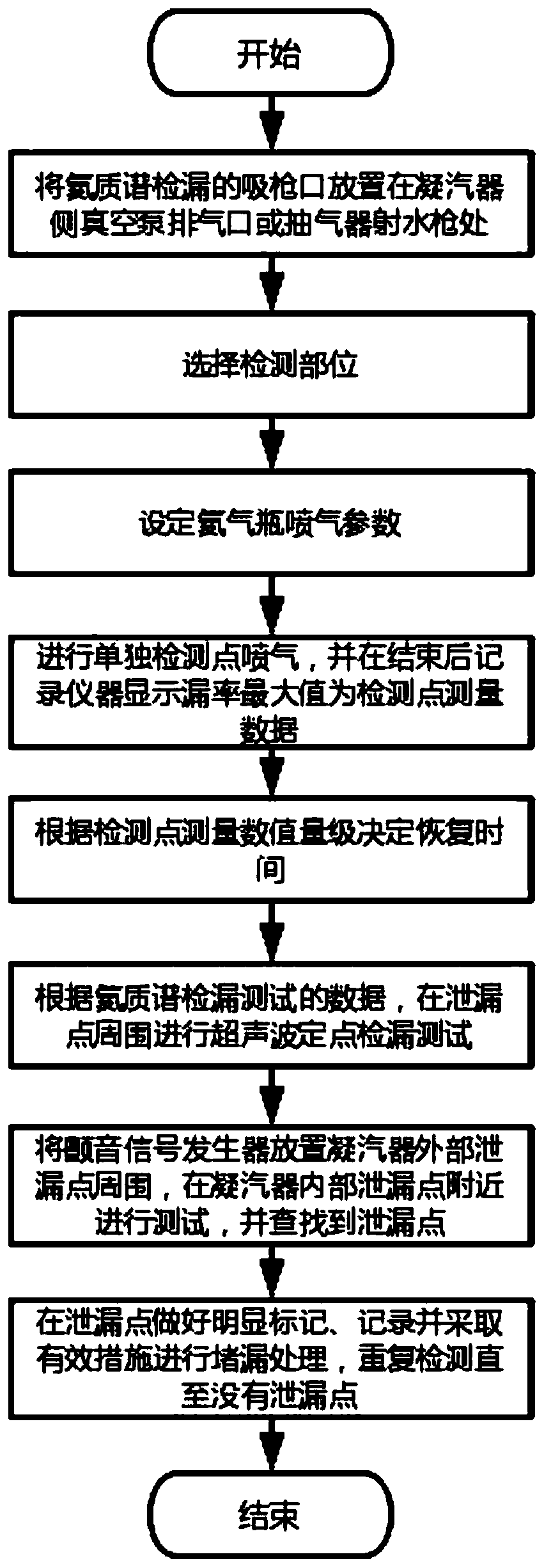

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

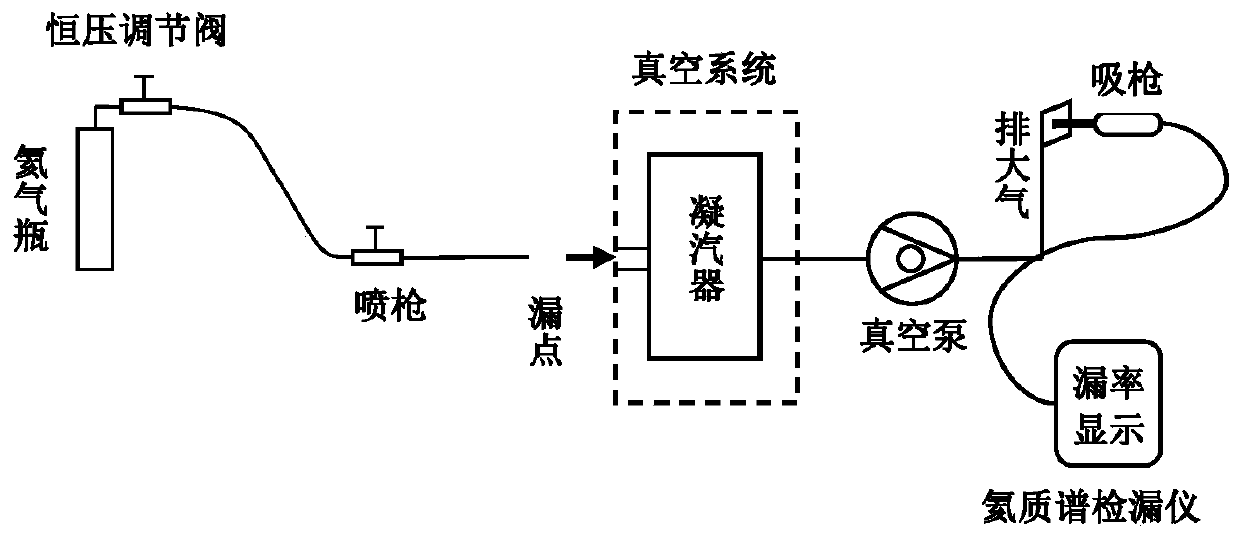

[0036] A comprehensive test device for leak detection of a steam turbine vacuum system, including a helium mass spectrometer leak detection system and an ultrasonic leak detection system, such as figure 2 As shown, the helium mass spectrometer leak detection system includes a helium gas bottle, a constant pressure regulating valve, a spray gun, a vacuum pump and a helium mass spectrometer leak detector, the helium gas bottle, the constant pressure regulating valve and the spray gun are connected in sequence, and the vacuum pump is connected to the condensate The vaporizer is connected, and the suction gun of the helium mass spectrometer leak detector is connected with the air exhaust port of the vacuum pump;

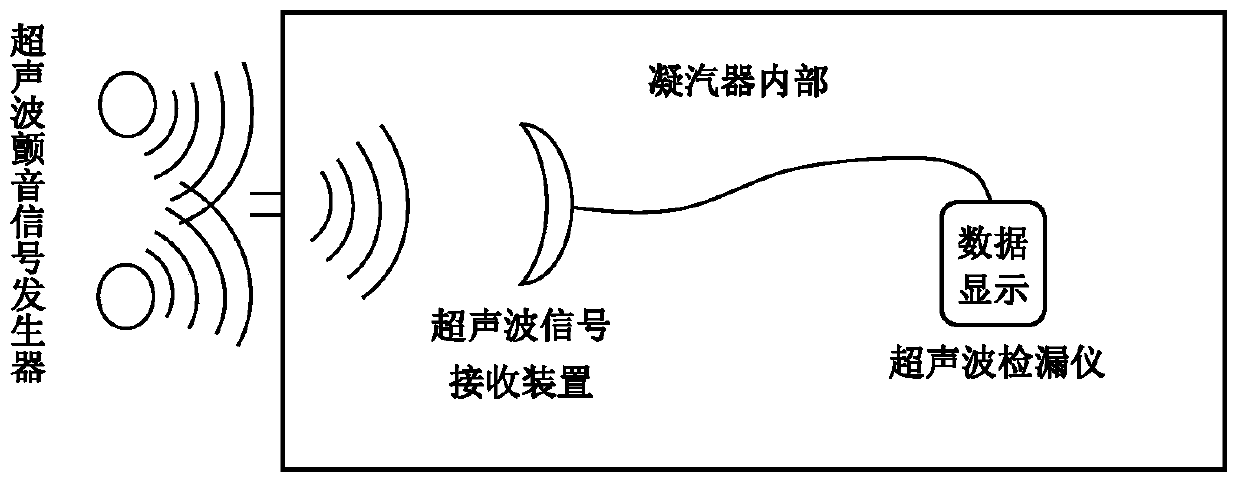

[0037] Such as image 3 As shown, the ultrasonic leak detection system includes an ultrasonic tremolo signal generator, an ultrasonic signal receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com