Pipeline detection robot

A pipeline inspection and robot technology, applied in the direction of supporting machines, pipe components, special pipes, etc., can solve problems such as operational difficulty and experimental errors, and achieve the effects of easy operation, reduced turning radius, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

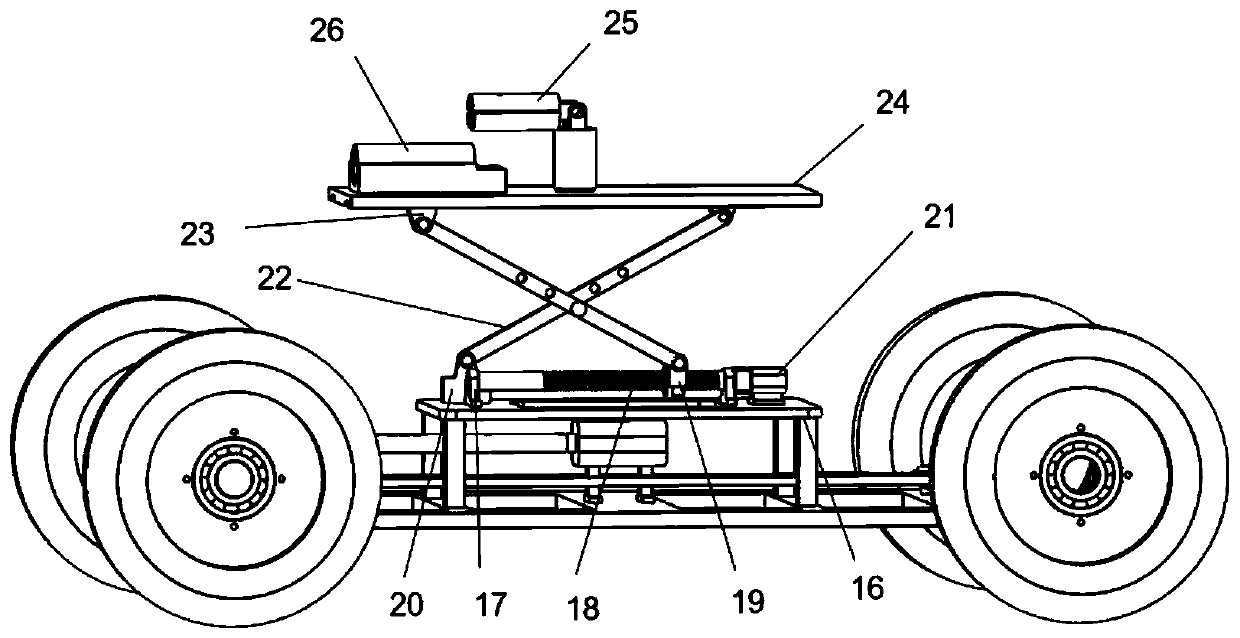

[0020] Such as Figure 1-3 Shown: a pipeline inspection robot, including a motion mechanism and a detection mechanism; the motion mechanism includes a base plate, four combined rods, two front tires 4-1, two rear tires 4-2, a first rack 5- 1. Second rack 5-2, first gear 6-1, second gear 6-2, drive motor 7, transmission shaft 8, differential 9, differential support frame 10, two universal joints 11 , steering gear 12, two axle shafts 13, two gear support frames 14 and two gear connecting rods 15; the two front tires 4-1 are symmetrically arranged on both sides of the front end of the base plate 1; the two rear tires 4 -2 is symmetrically arranged on both sides of the rear end of the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com