Improved storage shelf

An improved technology for storage shelves, which is applied in the direction of adjustable cabinets, household appliances, storage devices, etc., can solve the problems of sliding shelf compartments, low utilization of storage shelves, and low space utilization, so as to avoid rigid damage, The effect of improving the range of use and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

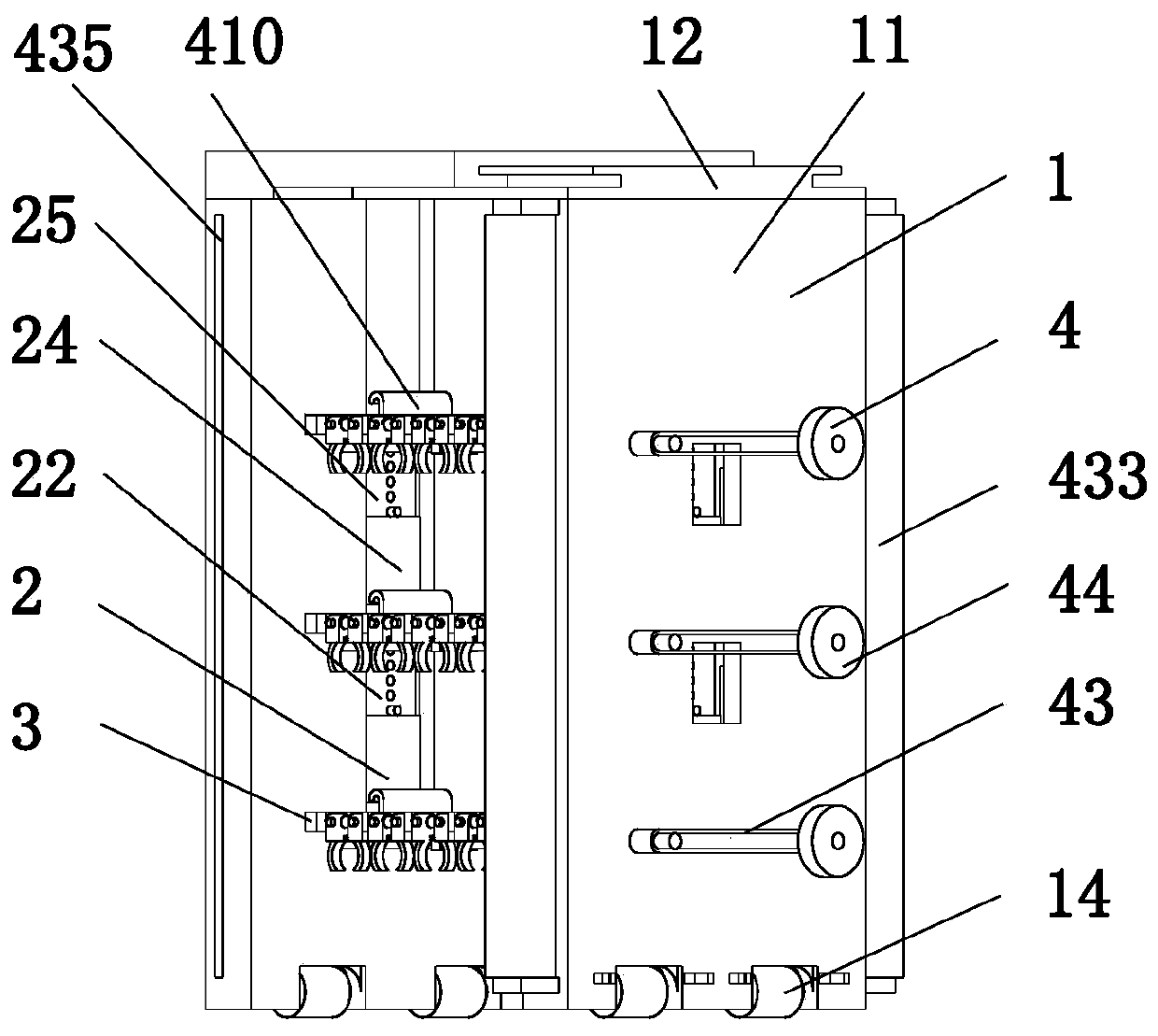

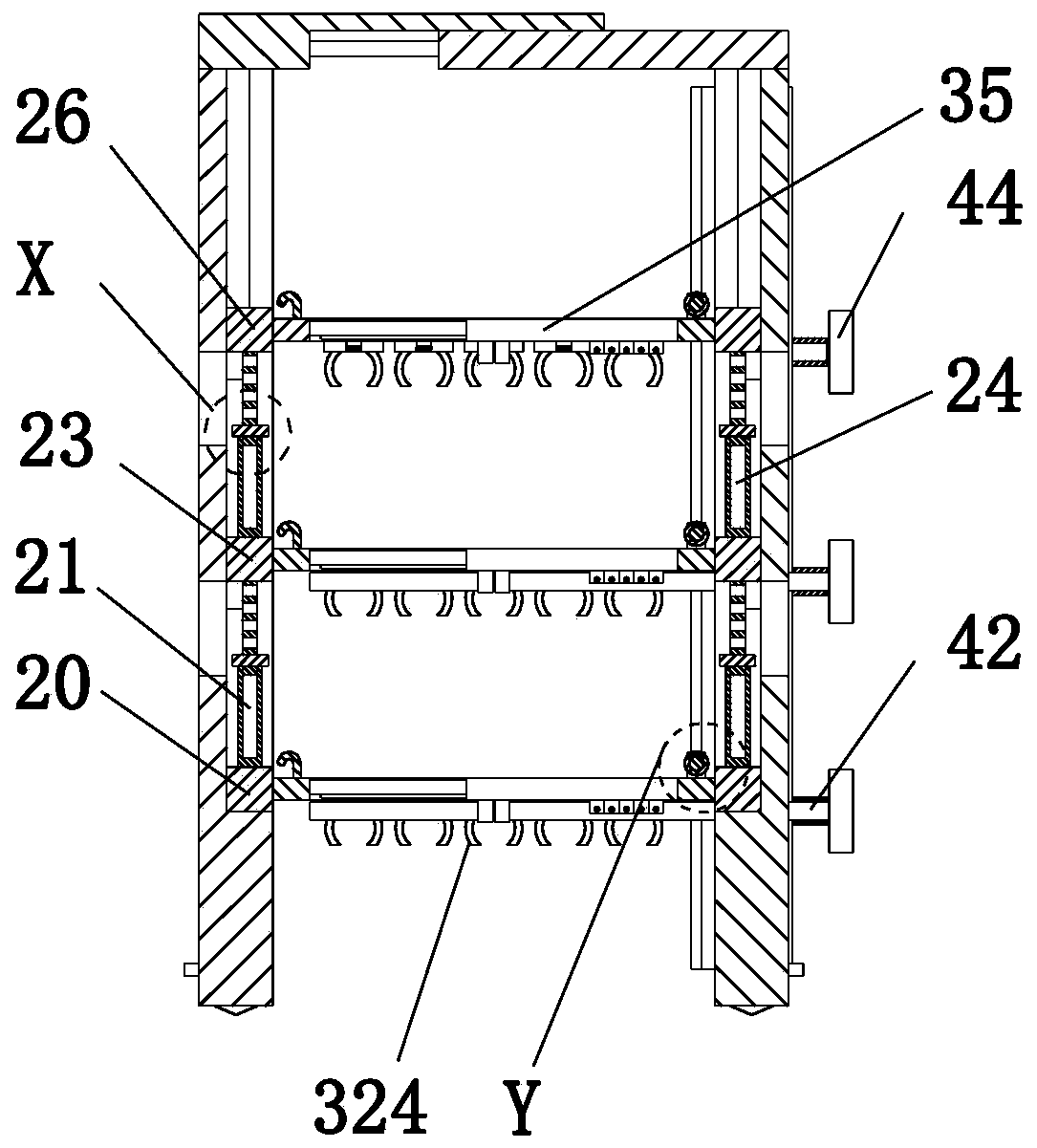

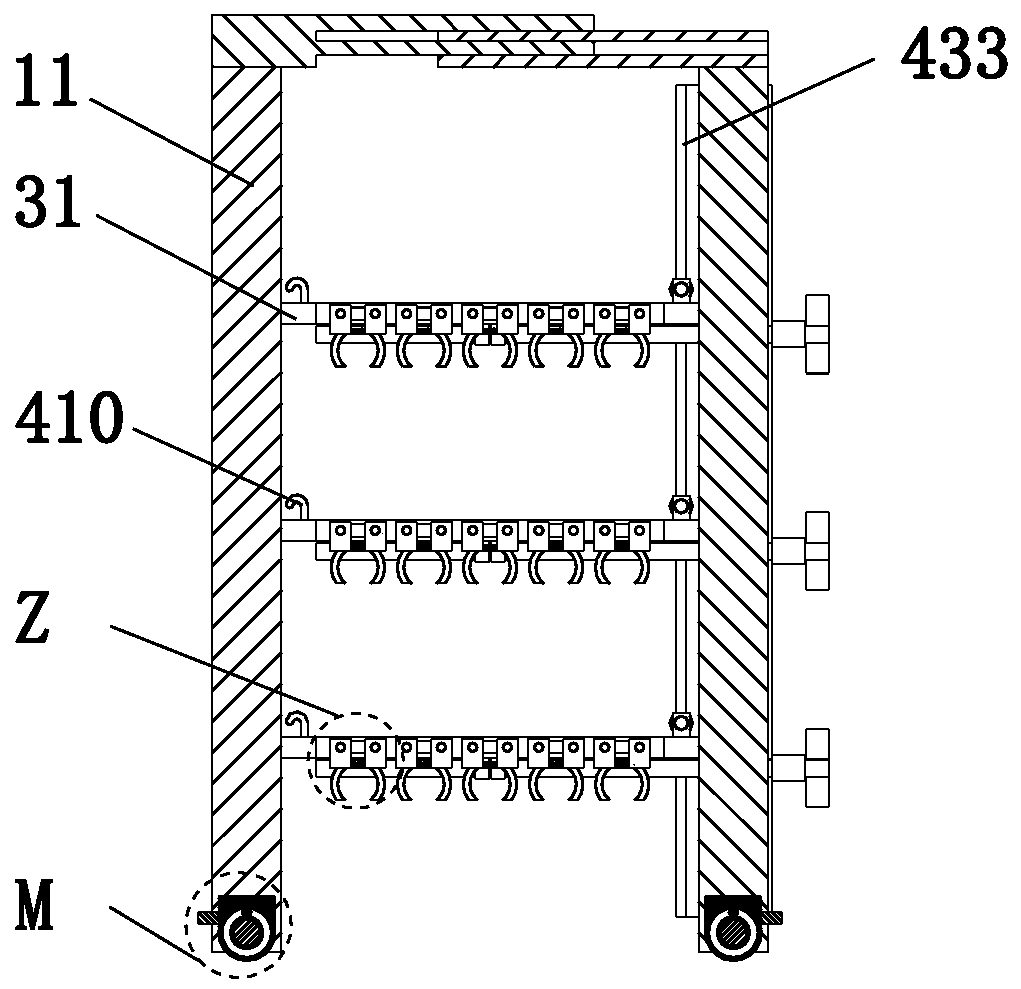

[0038] like Figure 1 to Figure 12 As shown, an improved storage shelf includes a frame body mechanism 1, a height adjustment mechanism 2, a plate group 3 and a width adjustment mechanism 4. The lower end of the frame body mechanism 1 is installed on the existing working ground by sliding fit. The frame mechanism 1 is arranged left and right, the inner end of the frame mechanism 1 is installed with a height adjustment mechanism 2 through a sliding fit, and the plate group 3 is installed equidistantly from top to bottom between the height adjustment mechanisms 2, and the lower right end of the plate group 3 Width adjustment mechanism 4 is installed.

[0039] The frame body mechanism 1 includes a vertical frame 11, a top plate 12, a connecting sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com