Die with ejector sleeve ejection structure

A cylinder and mold technology, applied in the field of injection molds, can solve problems such as tolerance, inability to guarantee the glue position of the boss, influence, etc., and achieve the effects of meeting product tolerance requirements, protecting the appearance surface, and facilitating demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

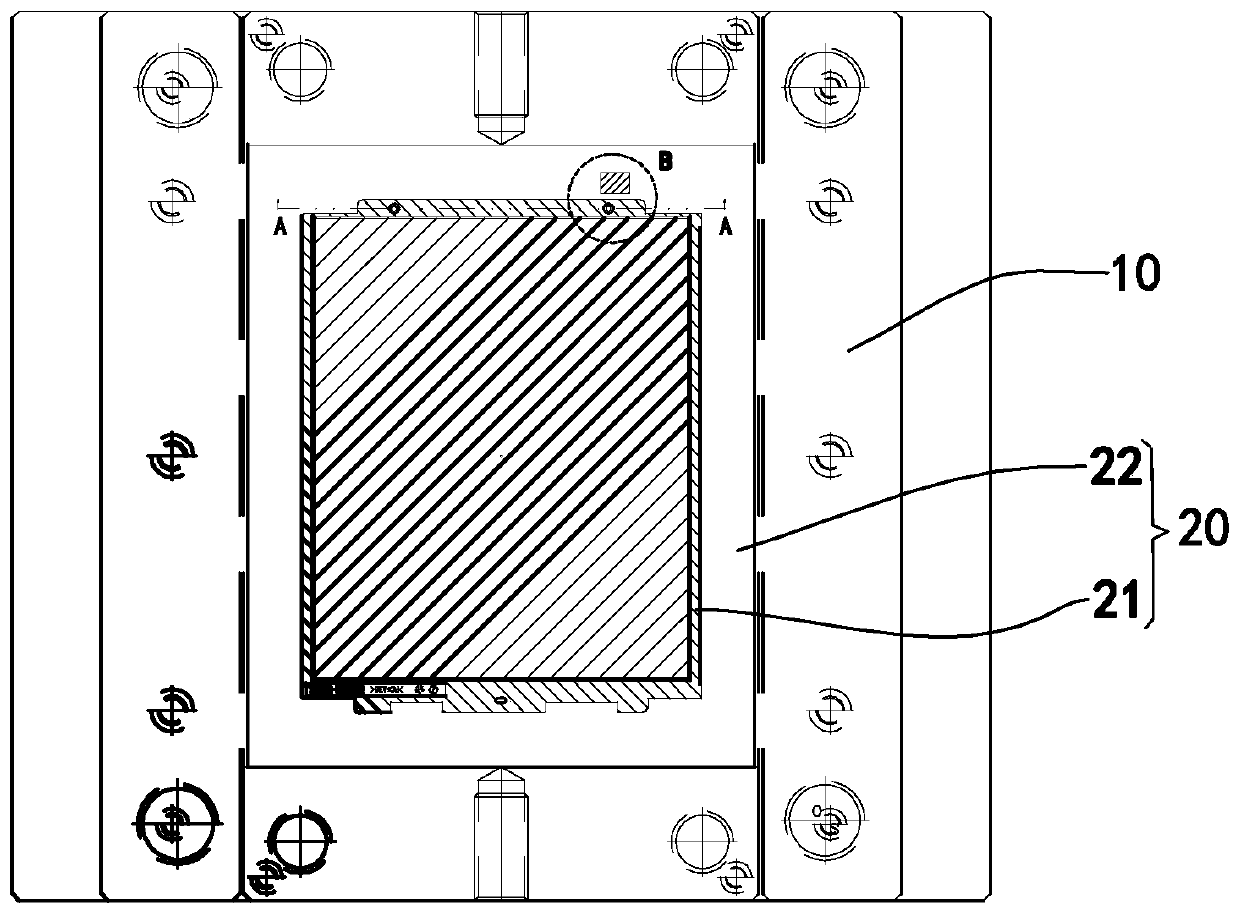

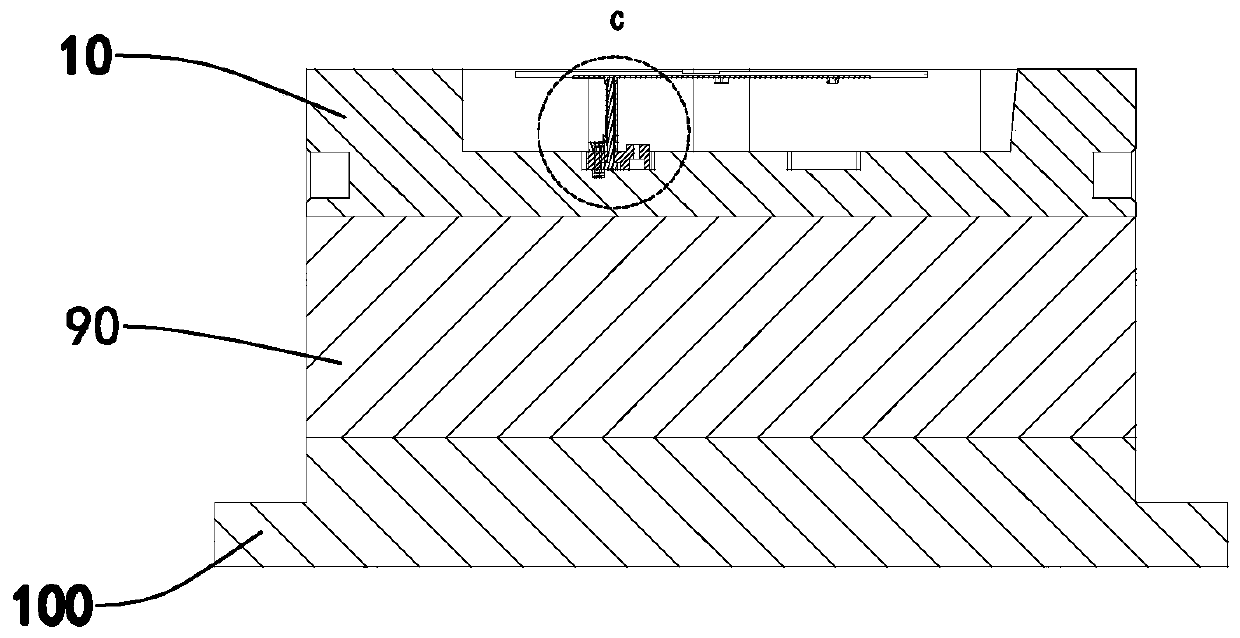

[0019] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a mold with a cylinder ejection structure, including a template 10, a module 20, a fixing plate 30, an insert pin 40, a cylinder 50, an elastic block 60, an elastic member 70, a pressing block 80, Stripper plate 90 and front mold panel 100.

[0020] Wherein, the module 20 is connected with the template 10 , and the module 20 can be embedded in the installation groove on the front of the template 10 . In this embodiment, the template 20 is connected on the stripper plate 90, and the stripper plate 90 is connected on the front mold panel 100, and the front mold panel 100, the stripper plate 90, the module 20 and the template 10 etc. constitute a front mold, The molds are matched to form a complete mold for injection molding, and the front mold is also provided with a flow channel for the plastic material to pass through.

[0021] The surface of the module 20 comprises a profiled area 21 and a contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com