Integrated high-automation vulcanizing machine

An integrated, vulcanizing machine technology, applied to other household appliances, household appliances, household components, etc., can solve the problems of high labor cost, high labor intensity and low work efficiency, and achieve high work efficiency and low labor intensity. , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

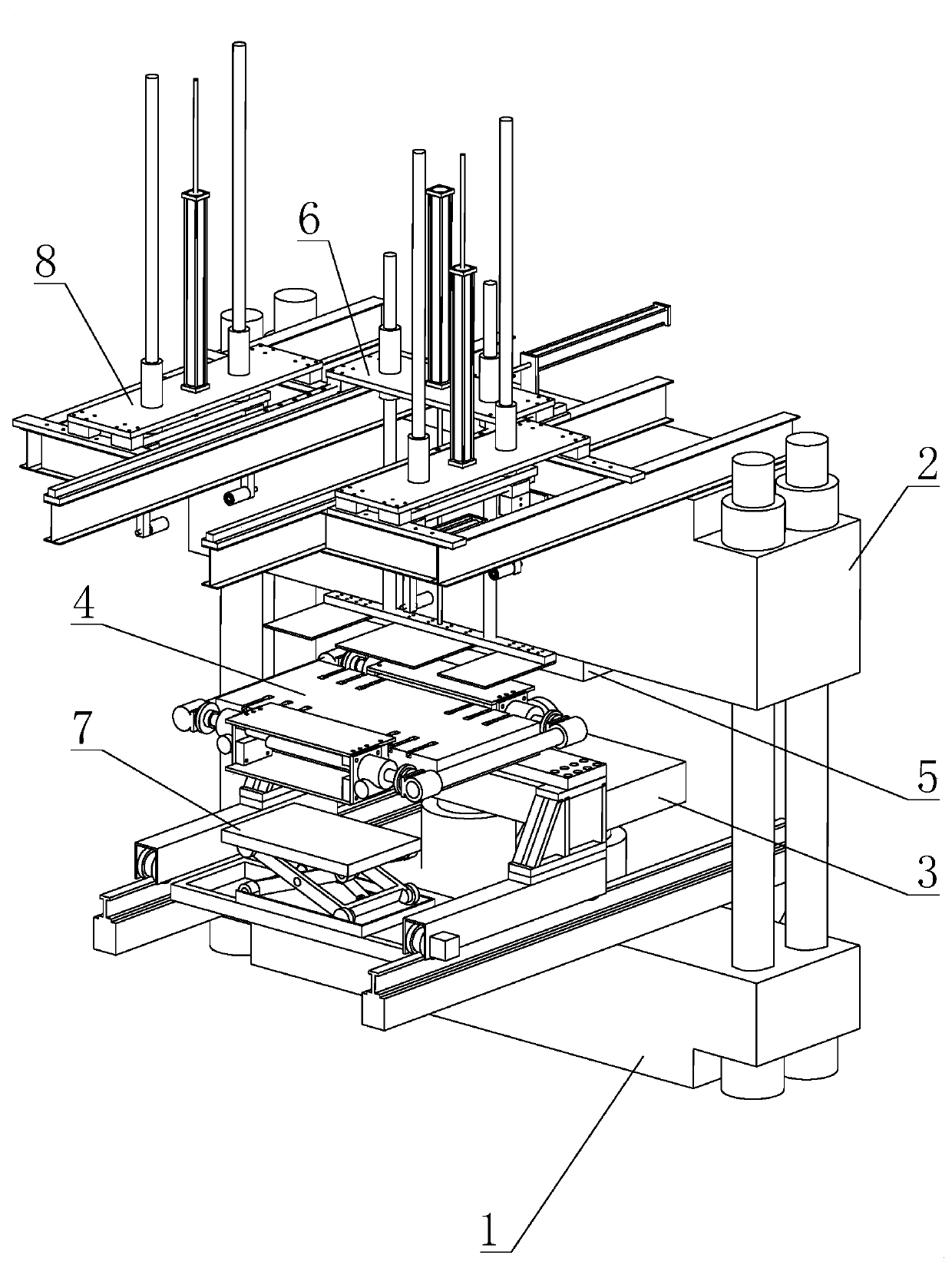

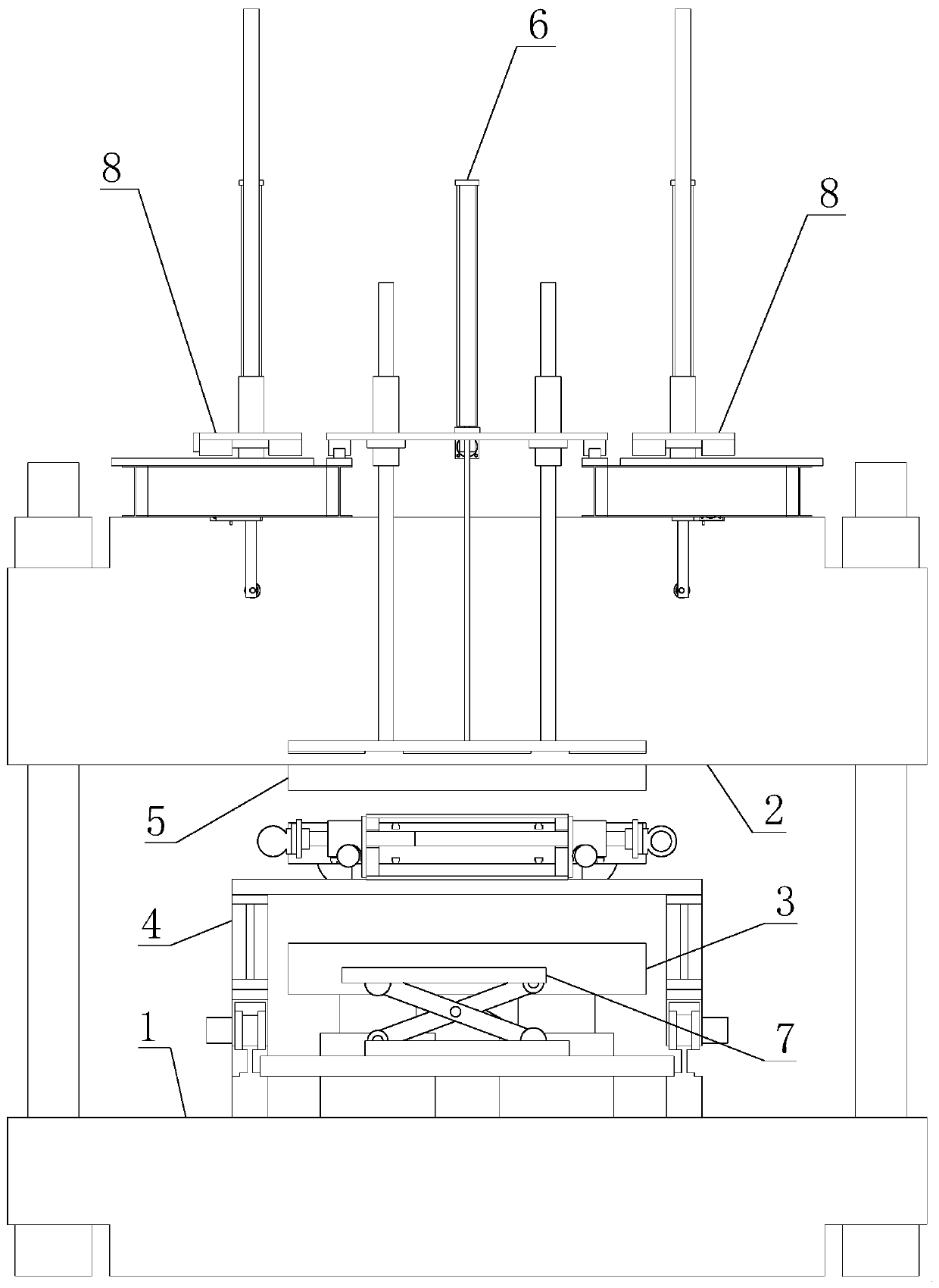

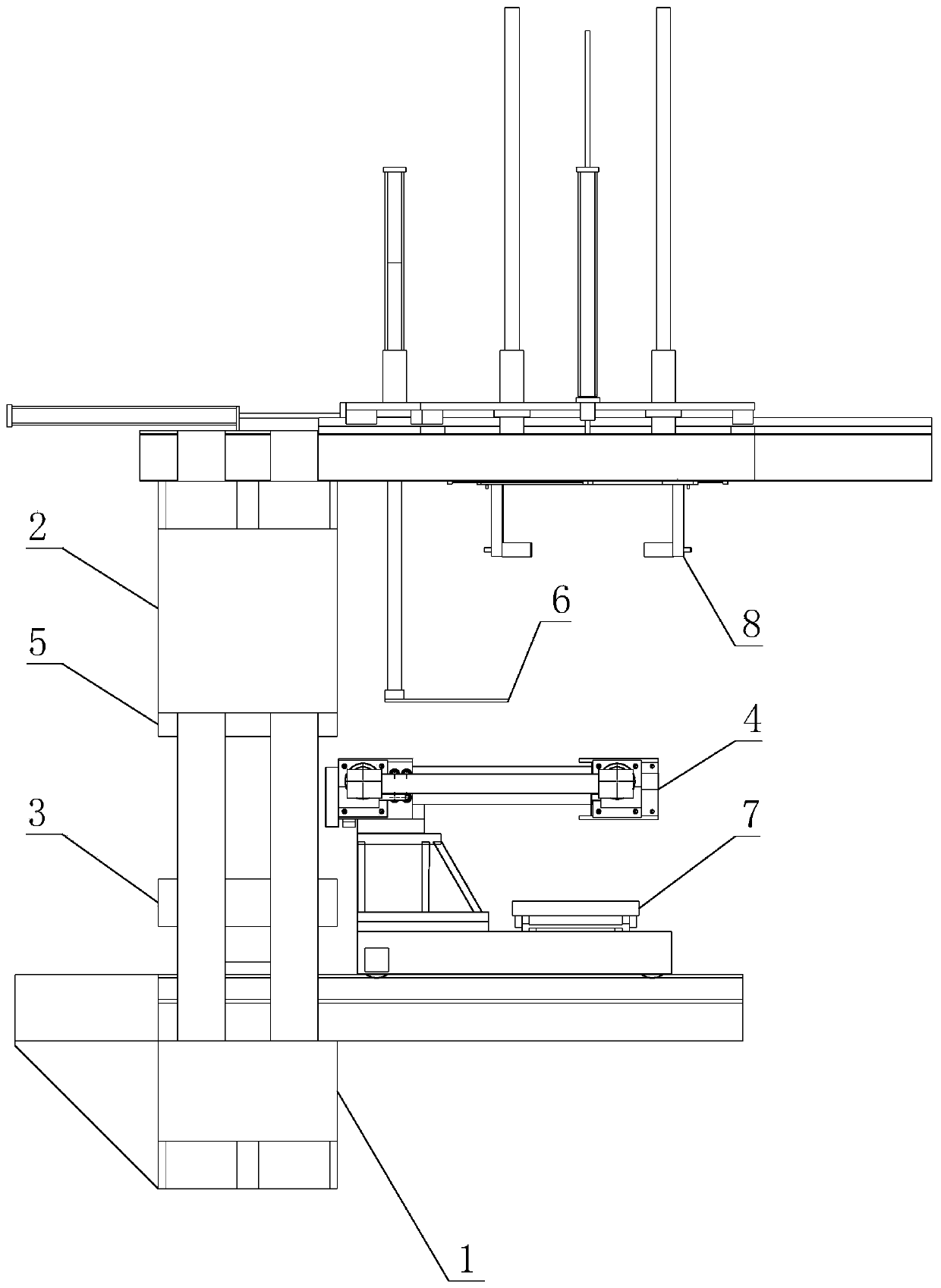

[0071] see Figure 1-7 , an integrated high-automatic vulcanizing machine, including a base 1, a top base 2, a lower hot plate 3, a middle hot plate car 4, an upper hot plate 5, a material hanging device 6, an alignment device 7, and two demoulding devices 8; The top seat 2 is fixed above the base 1; the lower hot plate 3 is connected to the base 1 through a hydraulic cylinder, and can be driven by the hydraulic cylinder to lift vertically; A door-shaped frame 401 that moves back and forth on the track, the top of the door-shaped frame 401 is provided with a heat plate 402, and the left and right sides of the heat plate 402 are respectively provided with a tension column 403 that can be driven by a motor to move horizontally. The door-shaped frame 401 is connected with a pair of rails arranged on both sides of the lower heating plate 3 and longitudinally distributed through the wheels at the bottom, and the door-shaped frame 401 can be driven by a motor to move forward along t...

Embodiment 2

[0087] see Figure 8-10 , different from Embodiment 1, in this embodiment, the support beam 8 of the medium-heating cart extends to the rear of the base 1, so that the medium-heating cart can be driven to the rear of the base 1; correspondingly, the base The rear of 1 is provided with transfer device 9. The belt transfer device 9 includes a belt transfer machine base 901 that can be driven by a hydraulic cylinder to move up and down vertically. The rear side of the belt roller bracket 902 is respectively provided with a belt transfer roller 903 which can be driven by a motor to rotate.

[0088] The process of using the integrated highly automated vulcanizing machine of this embodiment to vulcanize the rubber track preform can be as follows:

[0089] a. The vulcanizing machine is reset to the initial state; including the following actions: the lower heating plate 3 is lowered to the lowest position; the middle heating plate car 4 is driven to the processing position, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com