Chinese chestnut weighing device

A weighing device and technology for chestnut, applied in the directions of transportation and packaging, conveyor objects, sorting, etc., can solve problems such as inability to grade the appearance, inability to successfully complete the single-grain weighing of chestnut kernels, and inability to solve technical problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

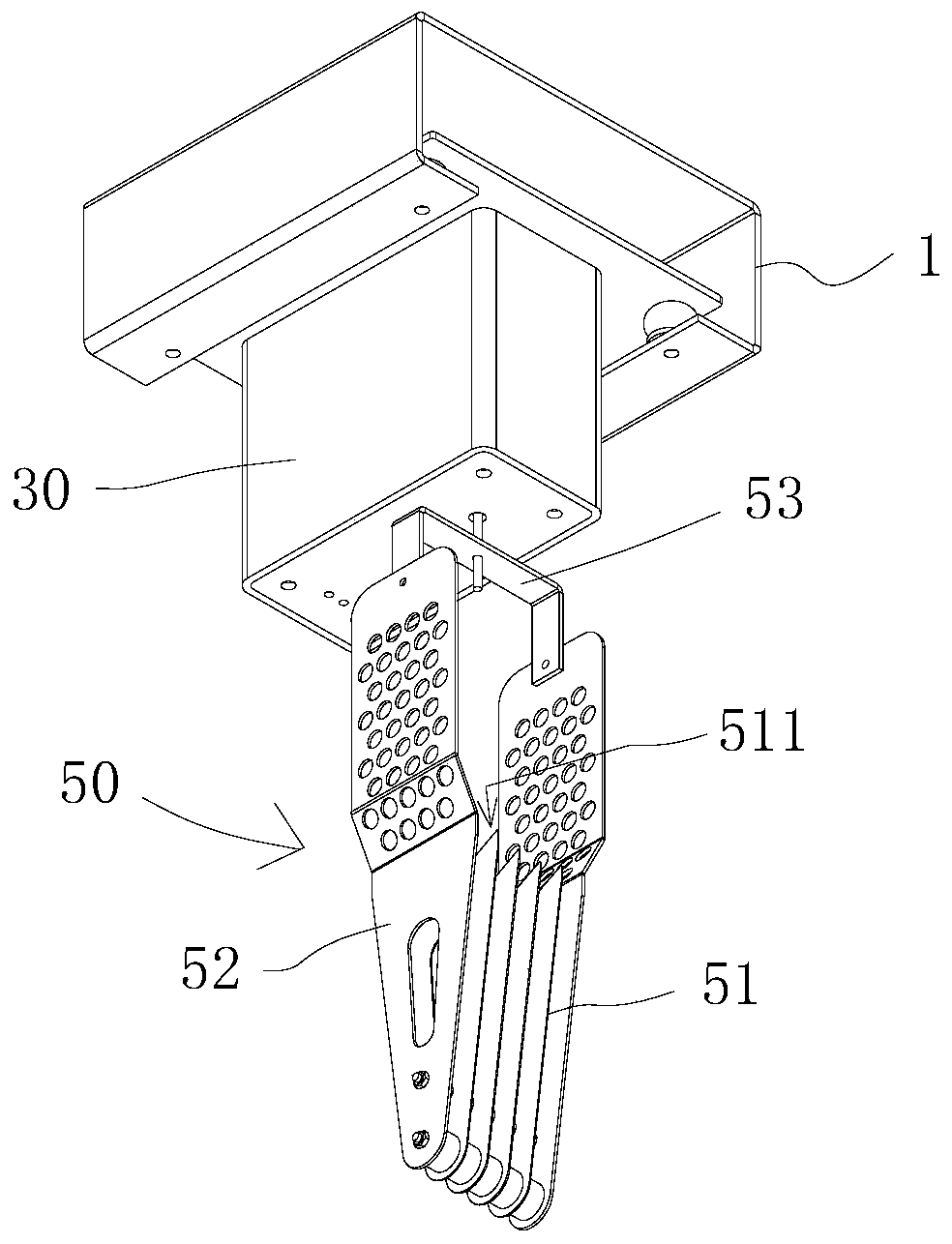

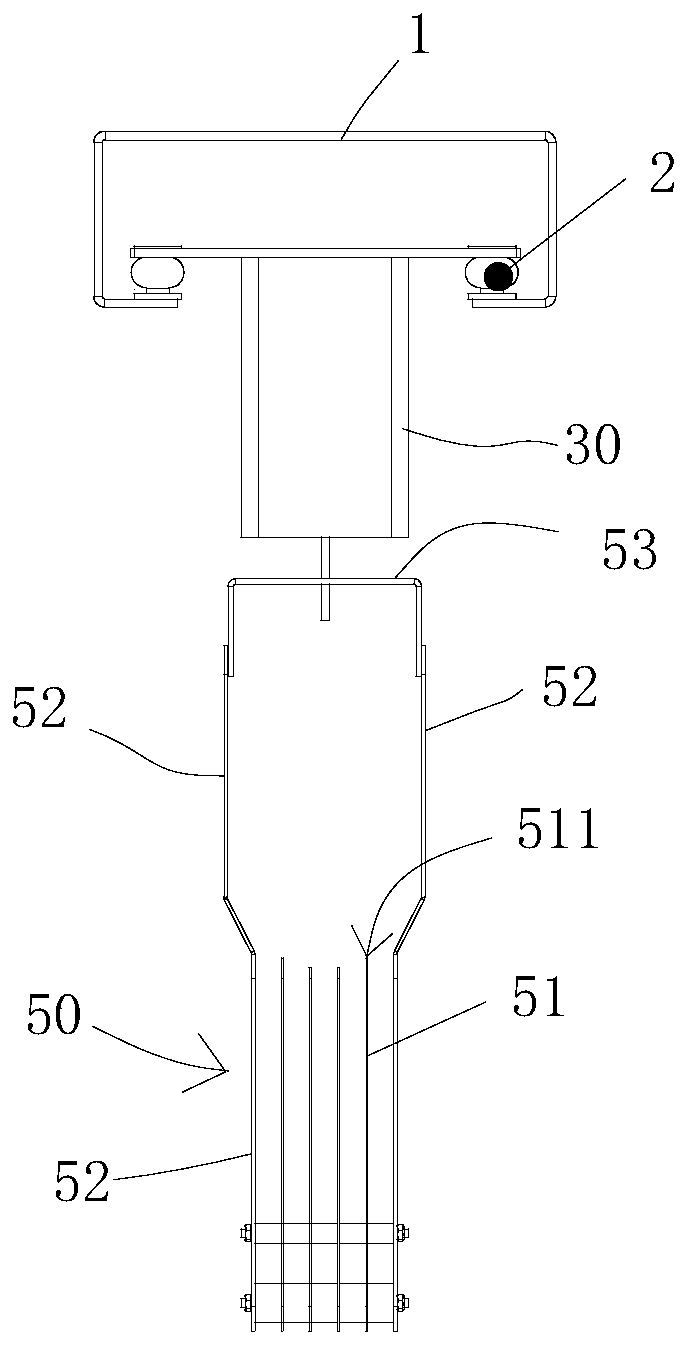

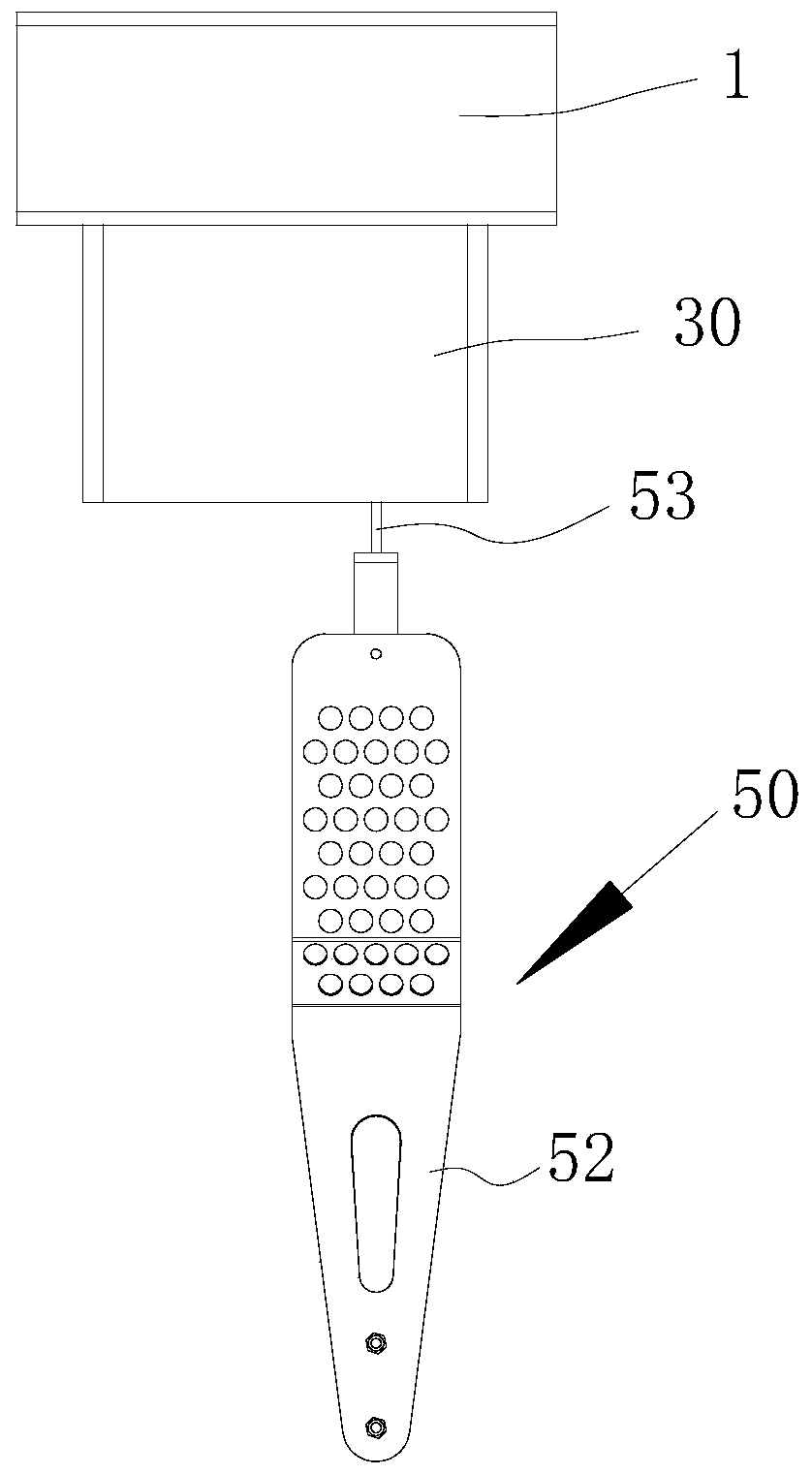

[0013] combine figure 1 , 2 3. Chestnut weighing device, the weighing bracket 50 is composed of mutually parallel toothed plates 51 arranged at intervals in the vertical plane, and the upper edge of the toothed plate 51 is the toothed side 511 of a single tooth valley, each The tooth valleys are arranged in the same position and form a V-shaped area supporting chestnut kernels. The weighing bracket 50 is connected with the measuring load cell 30 .

[0014] In the above scheme, the toothed plates 51 are arranged at intervals, and the positions of the toothed plates 51 are fixed to each other, and the tooth valleys surround a single V-shaped tooth valley area, and this V-shaped area is fully capable of accommodating and weighing a single chestnut kernel. In this way, the weighing bracket 50 corresponds to only one receiving part for the individual chestnuts conveyed at intervals by means of upstream equipment, so that the quality of a single chestnut kernel can be collected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com