Safety type power pipeline processing equipment

A technology of power pipelines and processing equipment, which is applied in metal processing and other directions, can solve the problems of workers accidentally touching the cutter, lack of protective treatment on the cutting blade, and cuts, so as to ensure safety, avoid people accidentally touching the blade and being injured, and avoid sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

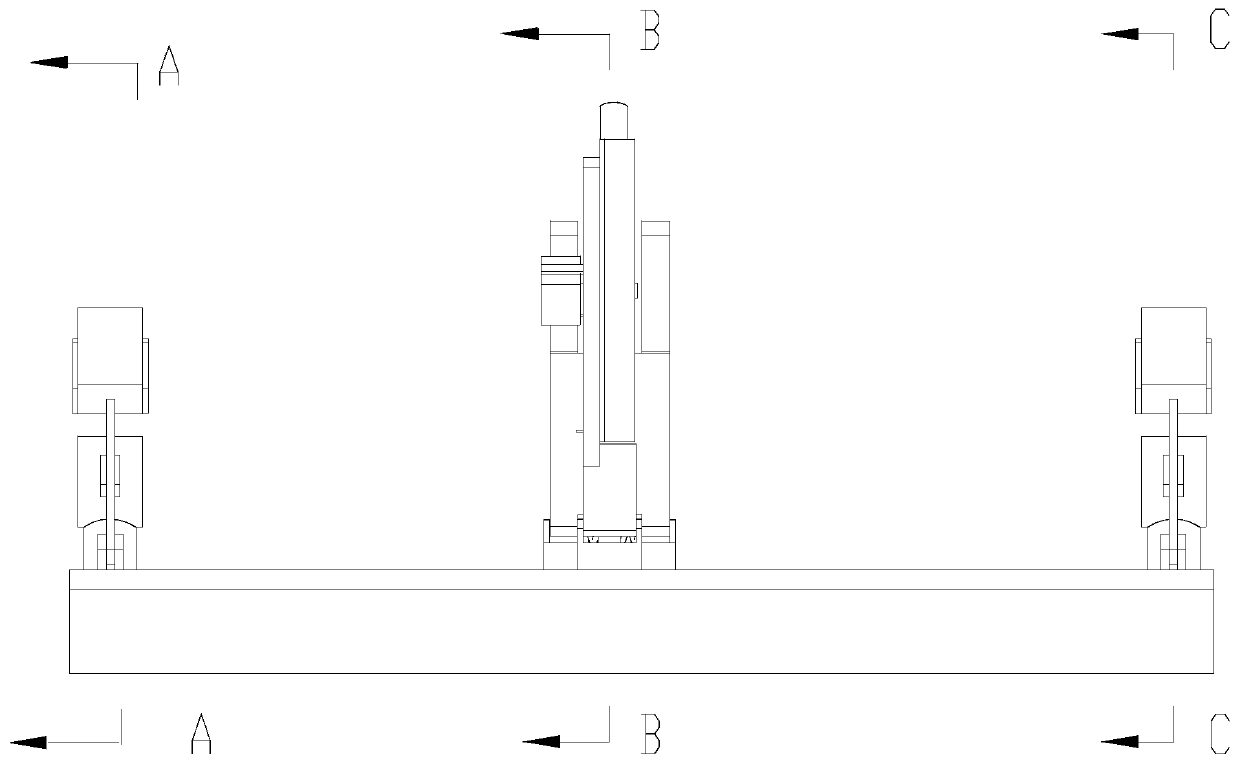

[0028] Such as Figure 1-10 As shown, a safe electric pipeline processing equipment includes a machine base 1, a support mechanism 2 and a cutting device 3; It is located between 2 sets of supporting mechanisms.

[0029] Such as figure 1 As shown, the cutting device 3 includes a sliding seat 4, a positioning mechanism 5, a cutting mechanism 6 and a clamping mechanism 8; the positioning mechanism 5 is arranged below the sliding seat 4; the cutting mechanism 6 is arranged on the sliding One end of the seat 4; the clamping mechanism 8 is located at the other end of the sliding seat 4.

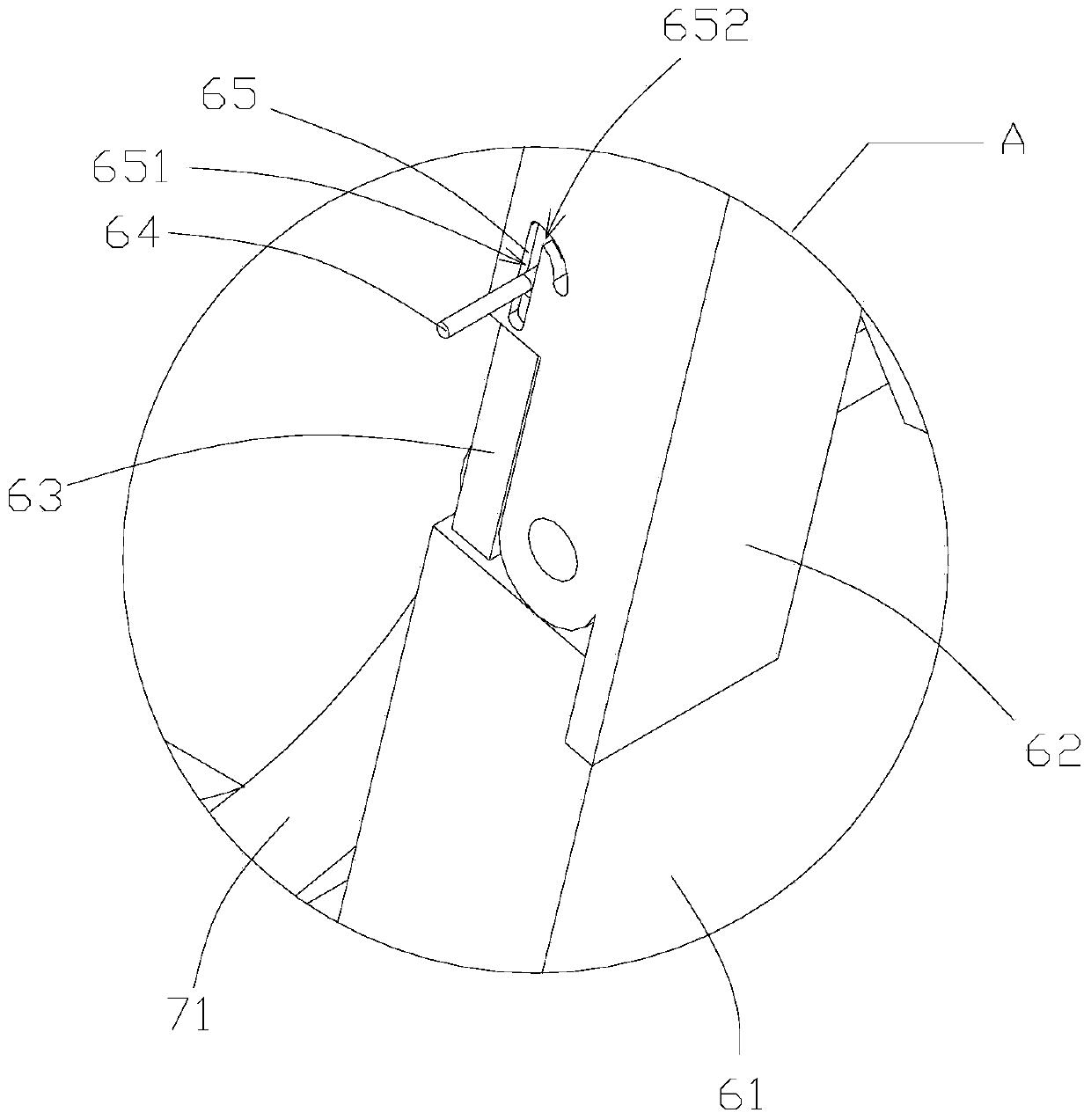

[0030] Such as Figure 1-5 As shown, the cutting mechanism 6 includes a first rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com