Large-grain seed directional positioning precision seeding device

A technology of precise seeding and directional positioning, applied in the field of agricultural machinery, can solve the problems of mutual blocking of leaves, interfere with the growth of seedlings, low operation efficiency, etc., and achieve the effects of slow speed, controllable position and angle, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

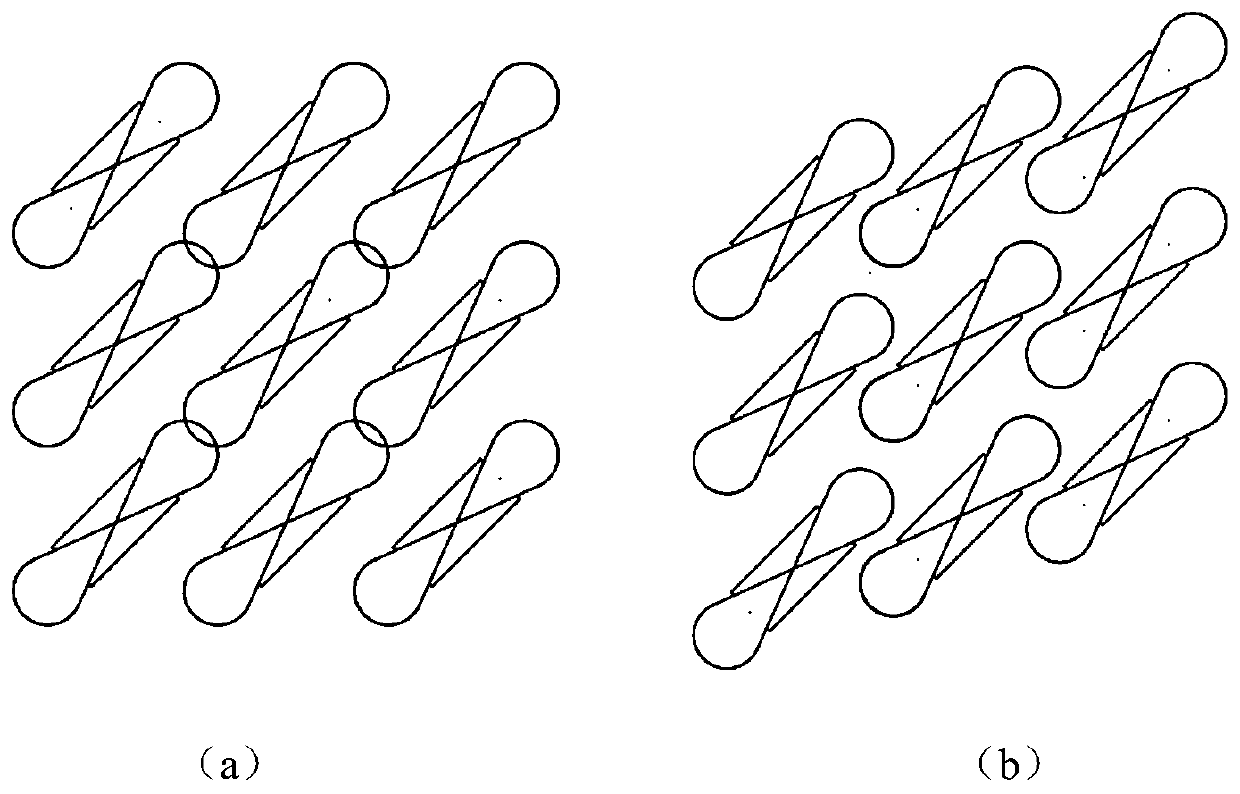

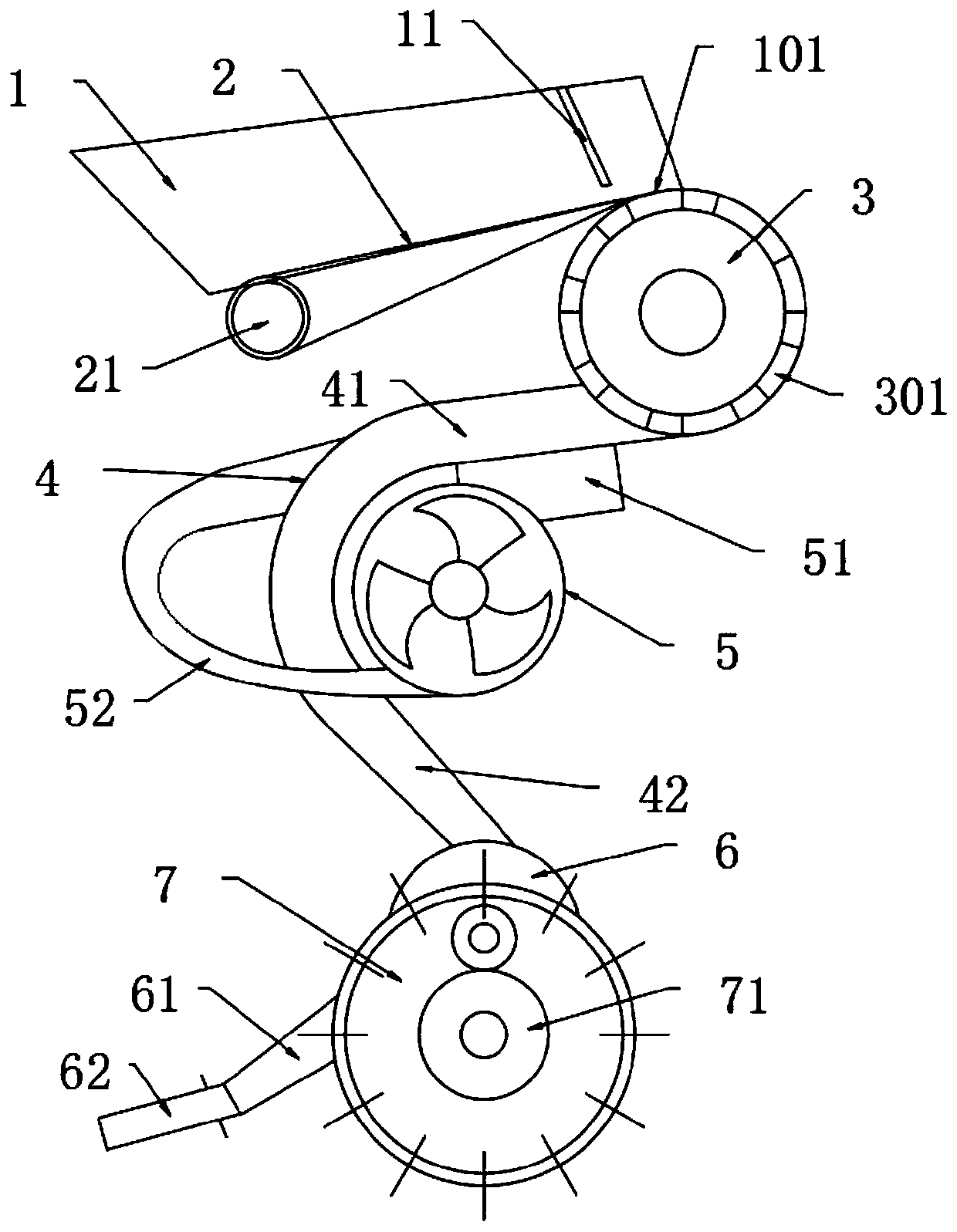

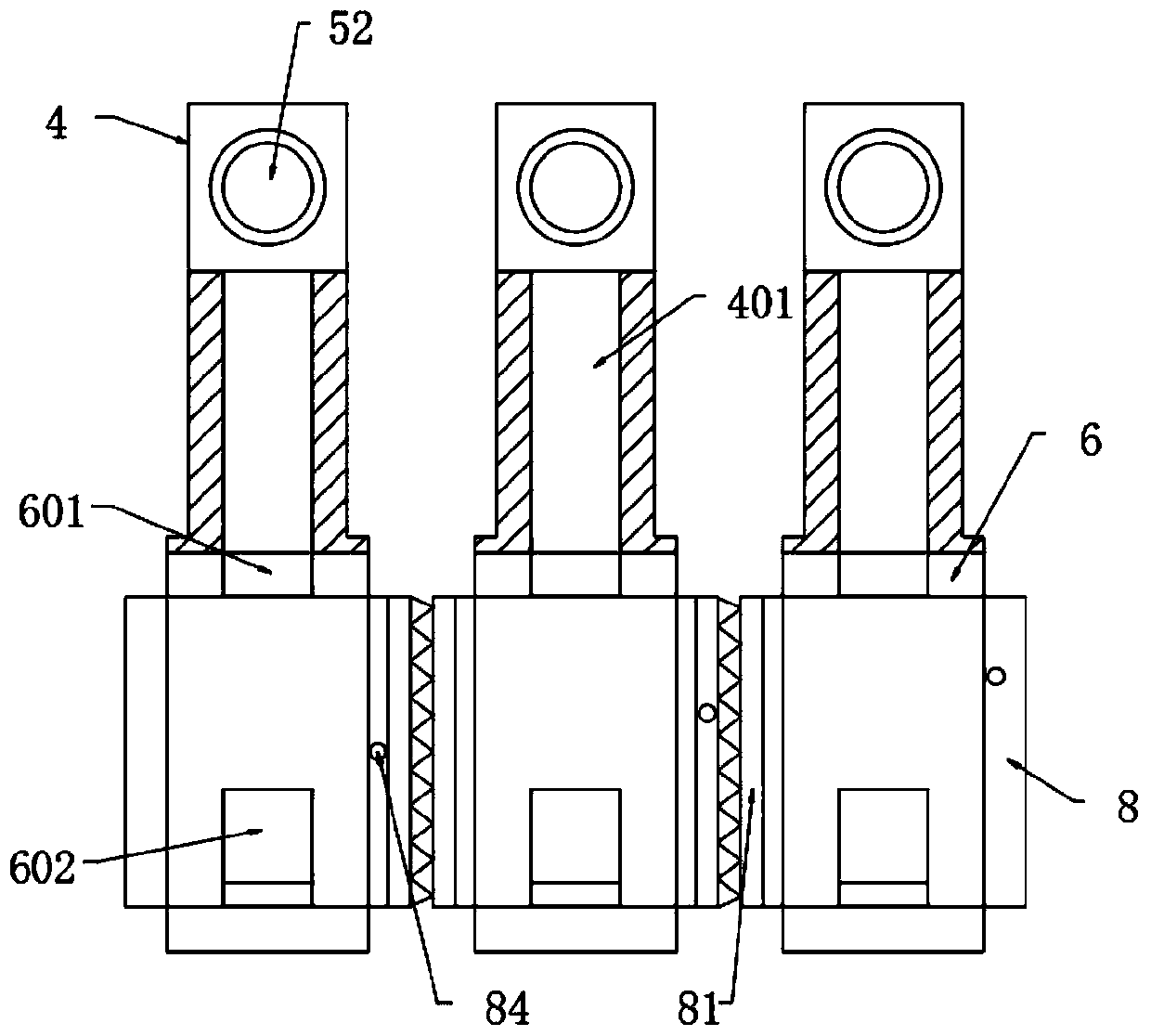

[0026] Example: such as Figure 1-7 As shown, a large-grain seed directional positioning precision seeding device includes a seed supply mechanism with a plurality of seed supply ports, and the output end of the seed supply mechanism is connected with several grooved wheel covers 6 correspondingly distributed with the seed supply ports, each The inner side of the sheave cover 6 is rotationally connected with a seed sheave 8, and several sheave sheaves 8 are fixedly connected in the circumferential direction, and two adjacent sheave wheels 8 have an included angle in the circumferential direction. A seed-discharging mechanism is provided, and the seed-feeding mechanism supplies seeds to the seed-supply port above the sheave cover 6. When the seed-dropping sheave 8 with a certain angle is rotating, every time a vertical seed groove on a seed-dropping sheave 8 801 and the seed supply port (such as Figure 4 When the middle vertical seeding groove 601) corresponds, the seed falls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com