Automatic wire clamp mounting tool

A technology of automatic installation and wire clamp, which is applied in the direction of clamp connection conductor connection, connection/termination cable equipment, etc., can solve the problems of safety risk, difficulty, low work efficiency, etc., and achieve the effect of simple operation and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

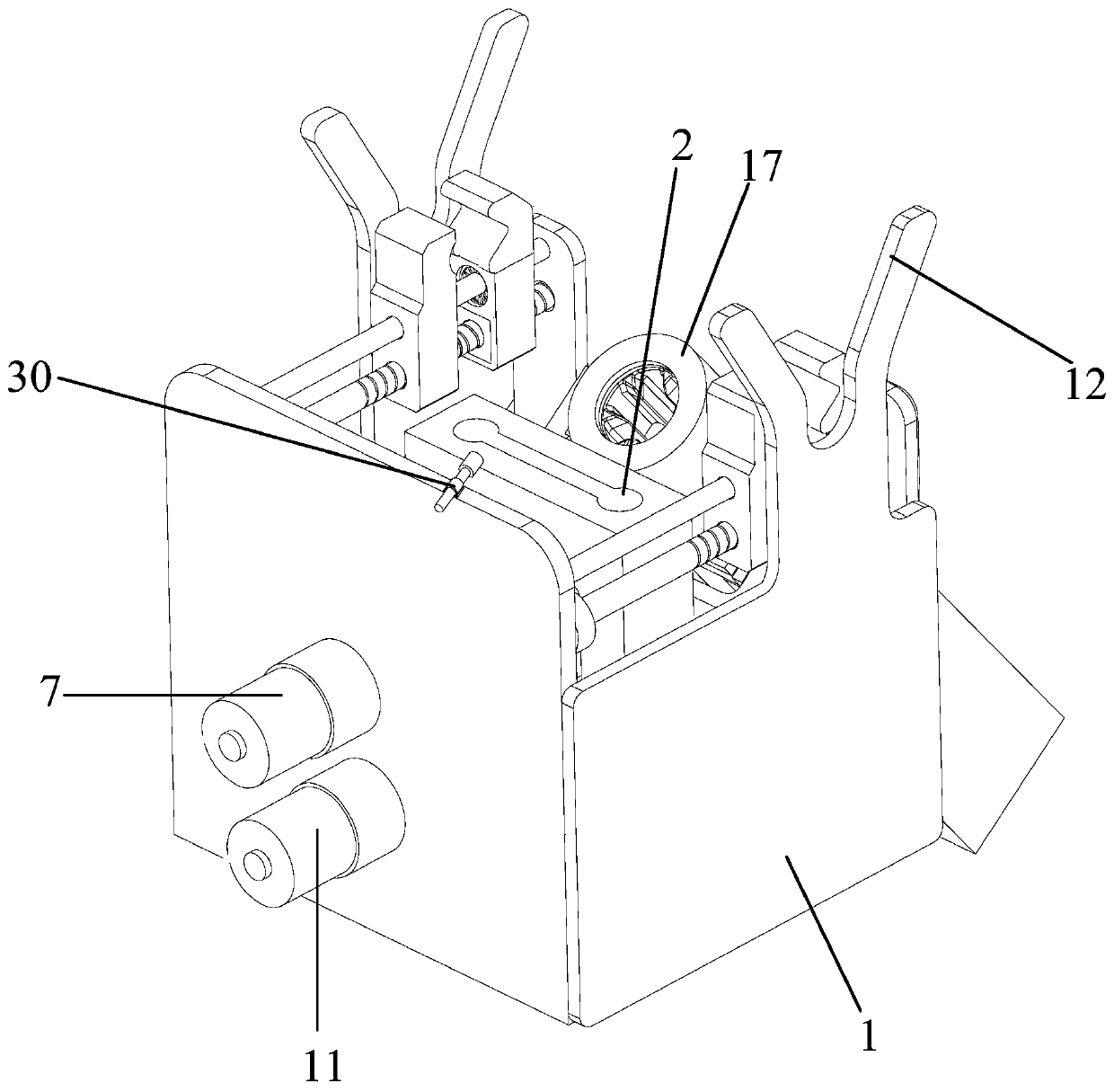

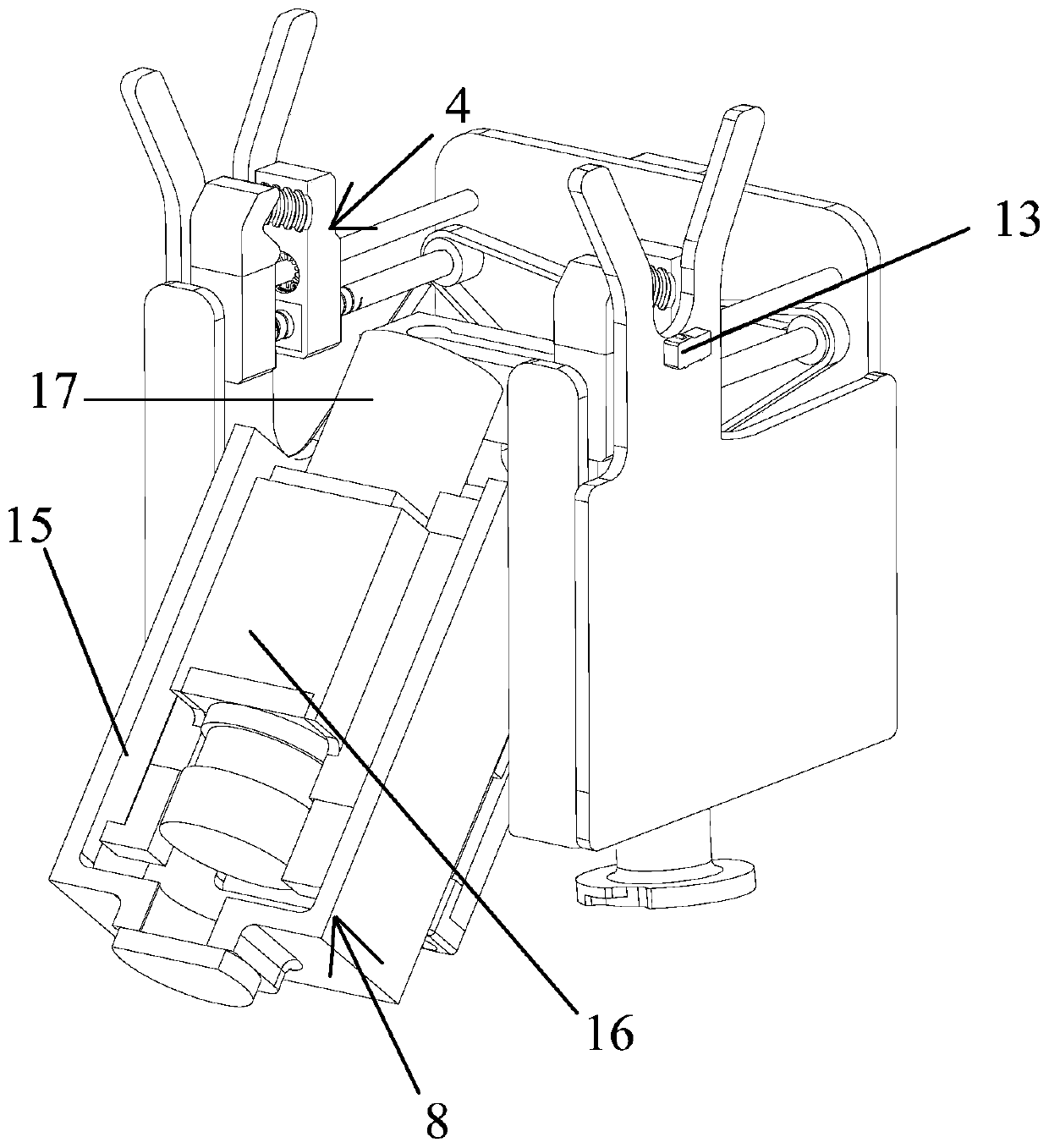

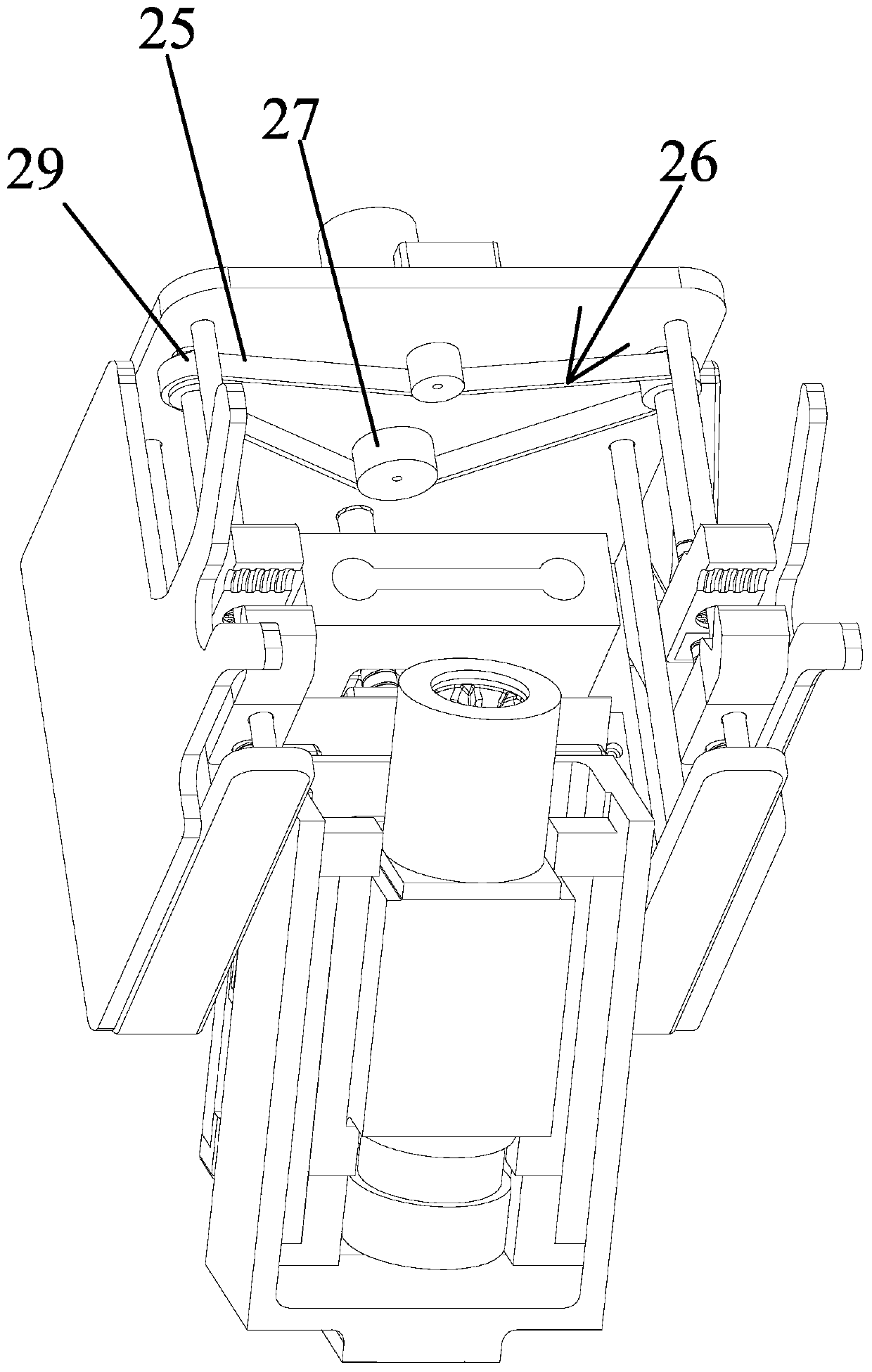

[0040] This embodiment provides an automatic wire clamp installation tool, such as figure 1 , figure 2 As shown, it includes: a frame body 1 installed on a moving arm. It includes: a wire clamp fixing frame 2 for installing the wire clamp 3; a wire locking device 4, which is arranged on the frame body 1, and the wire locking device 4 is provided with a drive to clamp or loosen the wire 9 The fastener 5; the wire clamp tightening device 8 is driven to be slidably arranged on the frame body 1, and is driven to be connected to or separated from the wire 9, and the wire clamp tightening device 8 is provided with a driver 17. The driving part 17 drives the wire clamp 3 to clamp the wire 9 or loosen the wire 9; in the prior art, the connection operation of the overhead insulated wire 9 still mostly uses the insulating glove method and the insulating rod operation method, It needs to be manually climbed on the pole or completed in the bucket arm truck. Although a safe distance is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com