A large-scale maintenance crusher for concrete pavement

A concrete pavement, a large-scale technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of manpower consumption, safety risks, low work efficiency, etc., and achieve the effect of improving work efficiency and automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

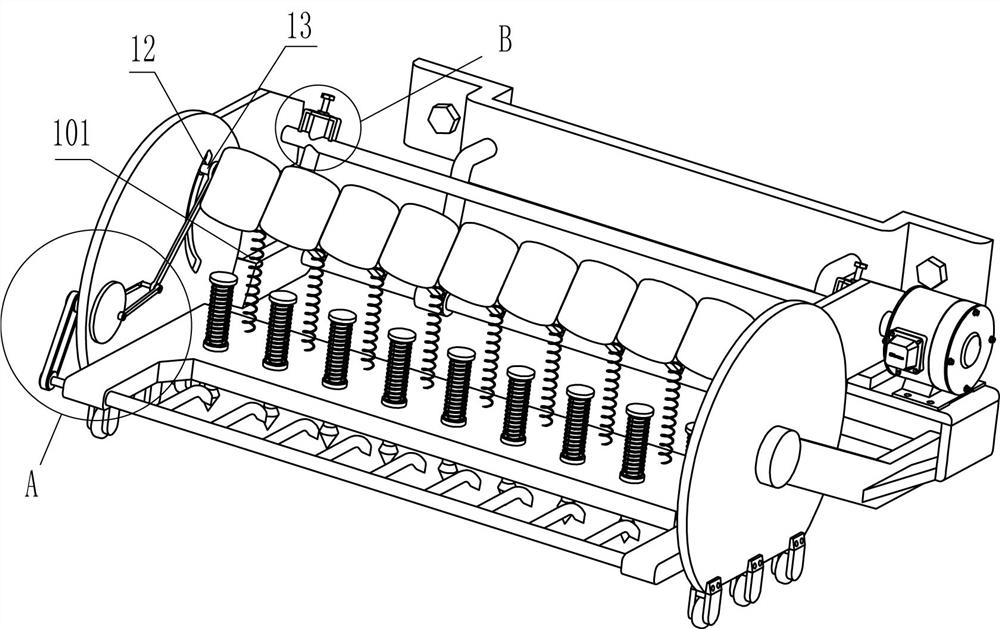

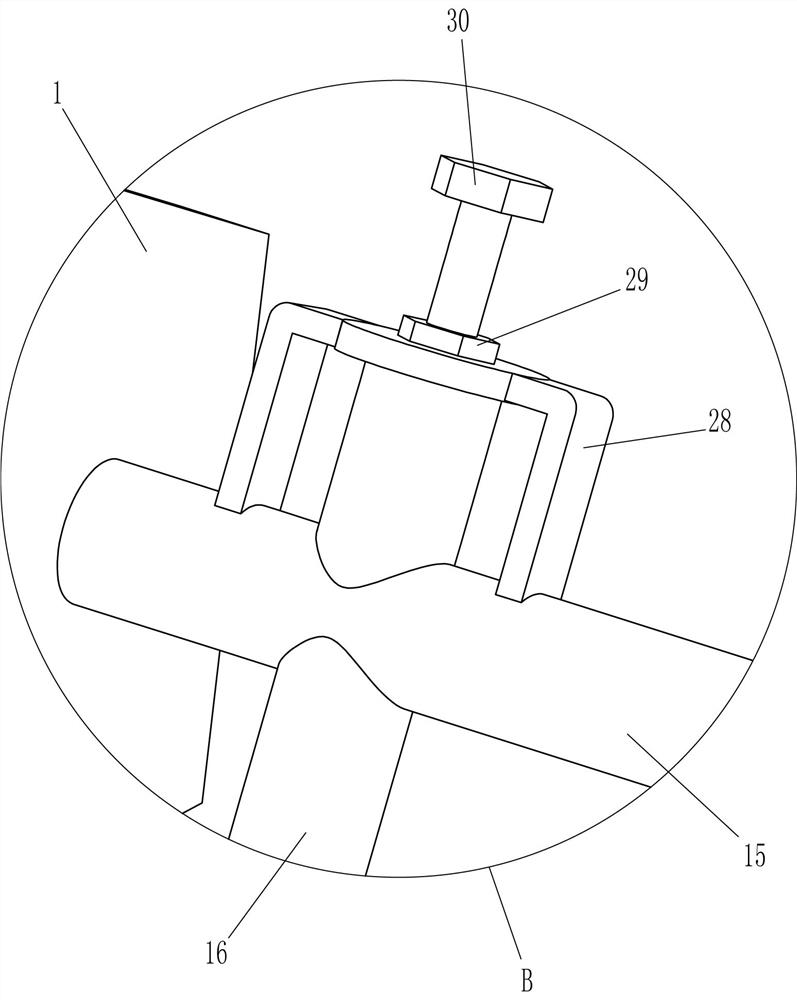

[0021] A crusher for extensive maintenance of concrete pavements such as figure 1 and 2 As shown, it includes a frame 1, a roller 2, a fixing assembly, a crushing assembly, a knocking assembly and a transmission assembly. The bottom of the frame 1 is equipped with a roller 2, and the front and rear sides of the frame 1 are provided with mounting brackets for connecting the equipment to the vehicle. Fixed components, frame 1 is provided with a crushing component for crushing the concrete pavement by sliding, between the left parts of frame 1 is provided with a knocking component for knocking through rotation, and the rear left part of frame 1 is provided with There is a transmission assembly powered by the motor to rotate and drive the crushing assembly to press down, and the transmission assembly cooperates with the crushing assembly.

[0022] like figure 1 As shown, the fixed assembly includes a fixed plate 3, a first cross bar 4 and a mounting plate 5, the front and rear s...

Embodiment 2

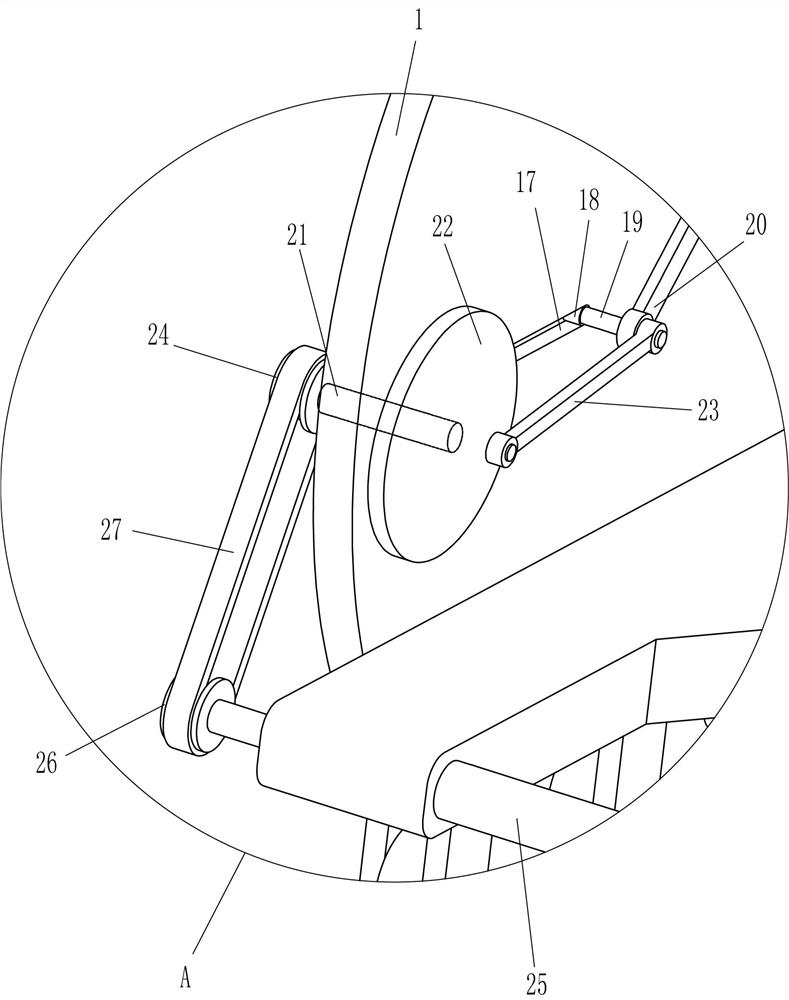

[0032] On the basis of Example 1, such as image 3As shown, in order to better clean up the concrete road surface, it also includes a second round shaft 18, a push rod 19, a second connecting rod 20, a second rotating rod 21, a rotating disk 22, a third connecting rod 23, a first pulley 24, toggle lever 25, second pulley 26 and flat belt 27, frame 1 front inside has horizontal and vertical sliding groove 17, and the sliding type in horizontal and vertical sliding groove 17 is provided with second round shaft 18, and the second round shaft 18 rear side Be provided with push rod 19, be provided with the second connecting rod 20 in rotation on the push rod 19, be connected in rotation between the second connecting rod 20 and the first connecting rod 13, frame 1 front right side rotating type is provided with the second Rotating bar 21, the second rotating bar 21 rear portion keys are connected with rotating disc 22, and the rotating type between rotating disc 22 and push rod 19 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com