Automatic welding trolley, automatic welding device and control method of automatic welding device

An automatic welding and trolley technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as limited travel, achieve the effects of simplifying the structure, ensuring welding quality, and ensuring steering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

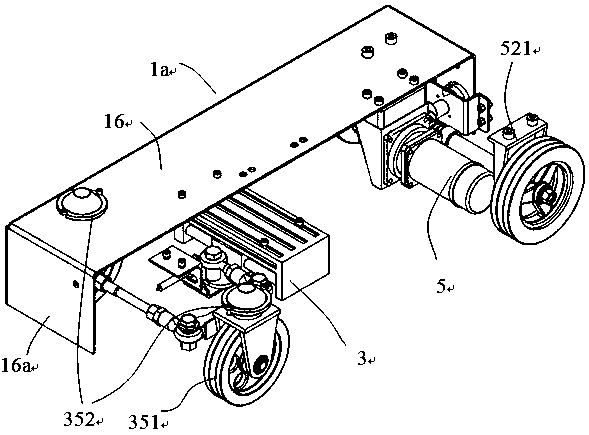

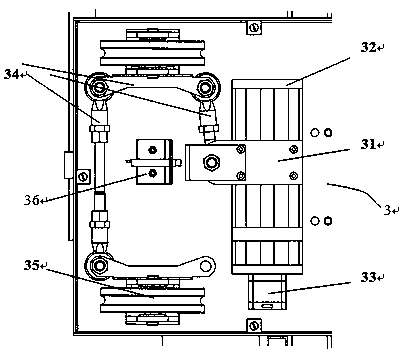

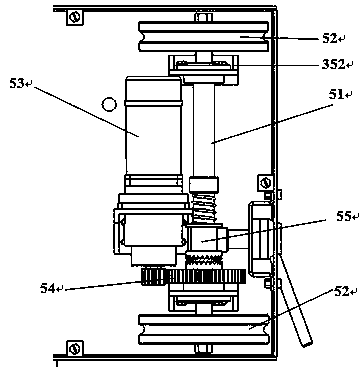

[0062] This embodiment provides an automatic welding trolley 1a, such as figure 1 As shown, it includes a walking component 5 for controlling the walking of the trolley, and a steering component 3 for controlling the steering of the trolley. Both the walking component 5 and the steering component 3 are installed on the frame support plate 16, so that the three form The trolley structure, the frame support plate 16 is a long strip structure, the steering component 3 and the walking component 5 are arranged under the frame support plate 16, and the steering component 3 is located in front of the traveling direction of the trolley. The component 5 is located at the rear of the traveling direction of the trolley. The traveling component 5 and the steering component 3 are arranged independently. The top of the frame support plate 16 is used to install weld detection components and welding components. The welding components are used for automatic butt welding. For welding, the weld de...

Embodiment 2

[0069] This embodiment provides an automatic welding device 1A, such as Figure 4 As shown, including the automatic welding trolley 1a in Example 1, the automatic welding trolley 1a is equipped with a weld detection component 1 and a welding component for automatic welding of the weld 4, and the weld detection component 1 is used For detecting weld information, the welding component is correspondingly arranged on the path of the weld detection component 1 for the weld detection, the welding component includes a welding controller 8, and the welding controller 8 is in communication connection with the weld detection component 1 , And control the steering component 3 and the walking component 5 through the received weld seam information, so that the automatic welding trolley 1a walks and tracks along the weld seam.

[0070] As one of the preferred embodiments, the steering component 3 and the walking component 5 are electrically connected to the welding controller 8, so that the wel...

Embodiment 3

[0084] This embodiment provides an automatic welding equipment applied to circular weld welding, such as Figure 4 with Image 6 As shown, it includes the automatic welding device 1A as described in Embodiment 2. The automatic welding device 1A is arranged on the annular weld, including the inner or outer side of the annular weld, and the annular weld consists of an arc-shaped workpiece to be welded 2 Splicing formation, the automatic welding device 1A is equipped with an inclination angle sensor, the inclination angle sensor is communicatively connected with the welding controller 8 and the control system of the external rotating mechanism 23, based on the data detected by the inclination angle sensor, and through the welding controller 8 and / Or the control system of the external rotation mechanism 23 controls the automatic welding trolley 1a to always be in the flat welding state, and the external rotation mechanism 23 is used to fix the workpiece 2 to be welded and controls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com