Tire performance testing device

A testing device and tire technology, which can be used in automobile tire testing, measuring devices, vehicle testing, etc., and can solve problems such as tires and vehicle safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

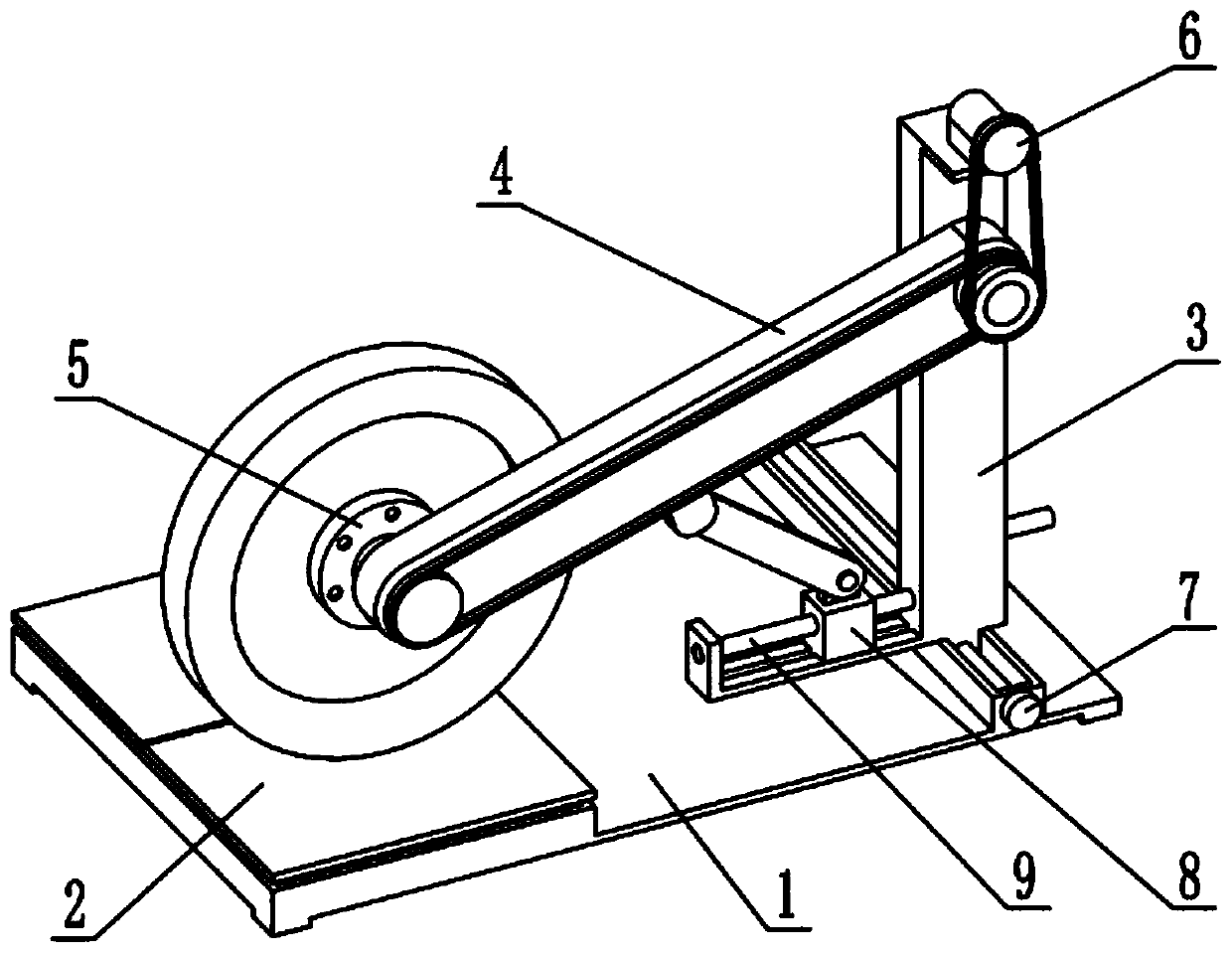

[0029] Such as Figure 1-10 As shown, a tire performance testing device includes a chassis 1, a testing mechanism 2, a support frame 3, a leg frame 4, a tire mounting mechanism 5, a power mechanism 6, a side deflection adjustment mechanism 7, a linkage mechanism 8 and a pressure adjustment mechanism. Mechanism 9, the test mechanism 2 is slidably connected to the front end of the chassis 1, the support frame 3 is slidably connected to the rear end of the chassis 1, and the rear end of the outrigger frame 4 is rotatably connected to the support frame 3 The upper end of the tire mounting mechanism 5 is rotatably connected to the front end of the outrigger frame 4, the testing mechanism 2 is located directly below the tire mounting mechanism 5, the power mechanism 6 is connected to the support frame 3, and the power mechanism 6 is connected to the tire The installation mechanism 5 is connected by transmission. The side deviation adjustment mechanism 7 is rotatably connected to the...

specific Embodiment approach 2

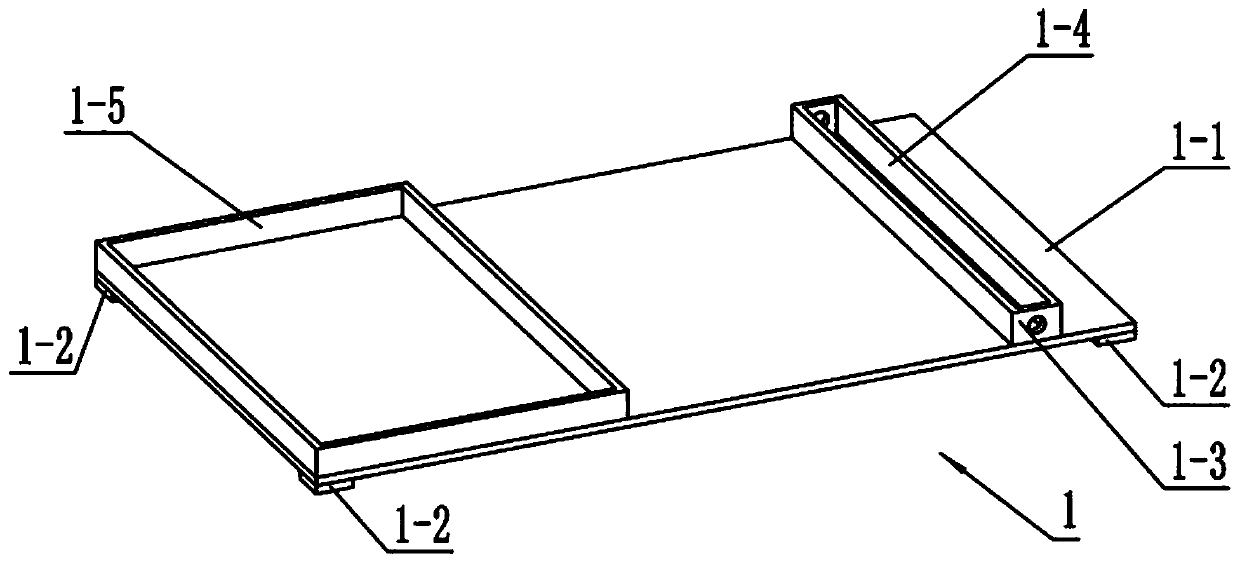

[0032] Such as Figure 1-10 As shown, the underframe 1 includes a base plate 1-1, a leg seat 1-2, a slide seat 1-3, a chute 1-4 and a limit frame 1-5, and the four corners of the base plate 1-1 are fixed The outrigger seat 1-2 is connected, the sliding seat 1-3 is fixedly connected to the rear end of the bottom plate 1-1, the sliding seat 1-3 is provided with a chute 1-4, and the limit frame 1-5 is fixedly connected to the bottom plate 1 -1, the bottom plate 1-1 in the limit frame 1-5 is provided with sensors, and the side walls inside the limit frame 1-5 are provided with sensors;

[0033]The sensors provided on the bottom plate 1-1 in the limit frame 1-5, and the sensors on the side walls inside the limit frame 1-5 are all connected to the external controller and display the corresponding process on it. Converted detection value.

specific Embodiment approach 3

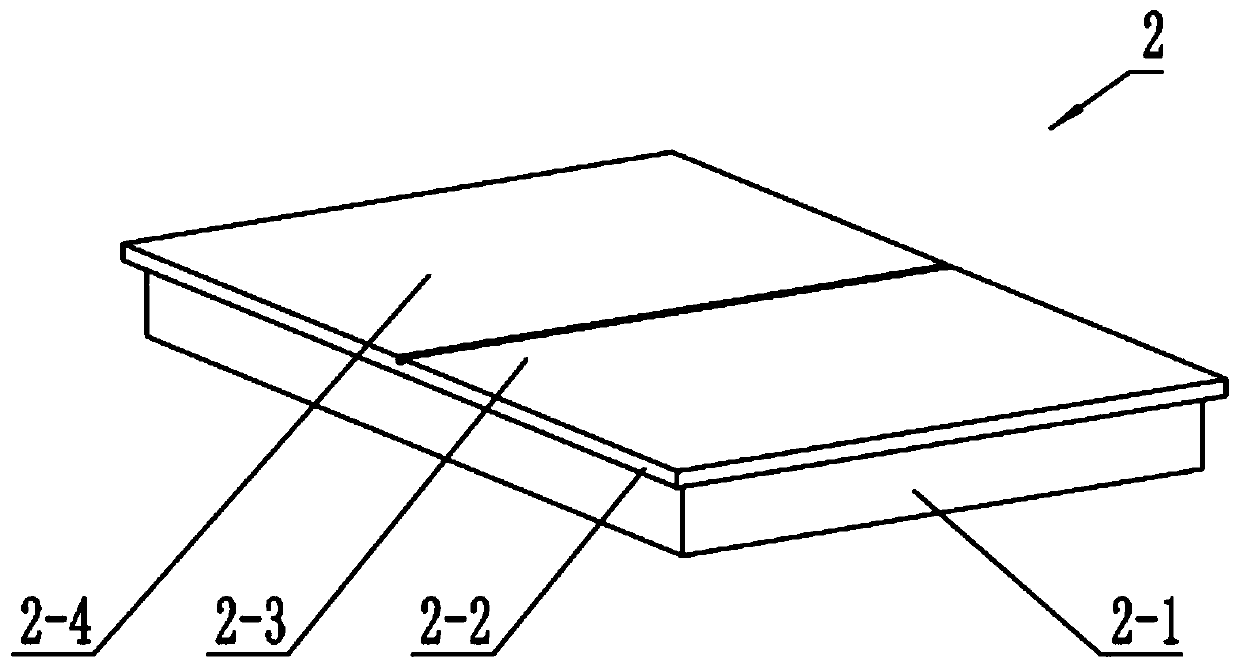

[0035] Such as Figure 1-10 As shown, the test mechanism 2 includes a test slide 2-1, a test board 2-2, a test surface I2-3 and a test surface II2-4, and the test board 2-2 is fixedly connected to the test slide 2-1. The upper end, the test surface Ⅰ2-3 and the test surface Ⅱ2-4 are respectively arranged at the left and right ends of the upper end surface of the test board 2-2, the test slide 2-1 is slidably connected in the limit frame 1-5, and the test slide 2- 1 contact with multiple sensors;

[0036] By testing different road conditions on the test surface I2-3 and test surface II2-4, the tire performance under different road conditions can be detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com