A construction method for reducing blasthole control over and under-excavation in an inclined flat-curve tunnel

A construction method and inclined flat technology, which is applied in tunneling, blasting, earthwork drilling and mining, etc., can solve the problems of reducing the degree of over- and under-excavation of curved side walls, increasing the cost of construction measures, and low acceptance by the construction party, so as to reduce over-under-excavation Excavation volume, reduced construction cost, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

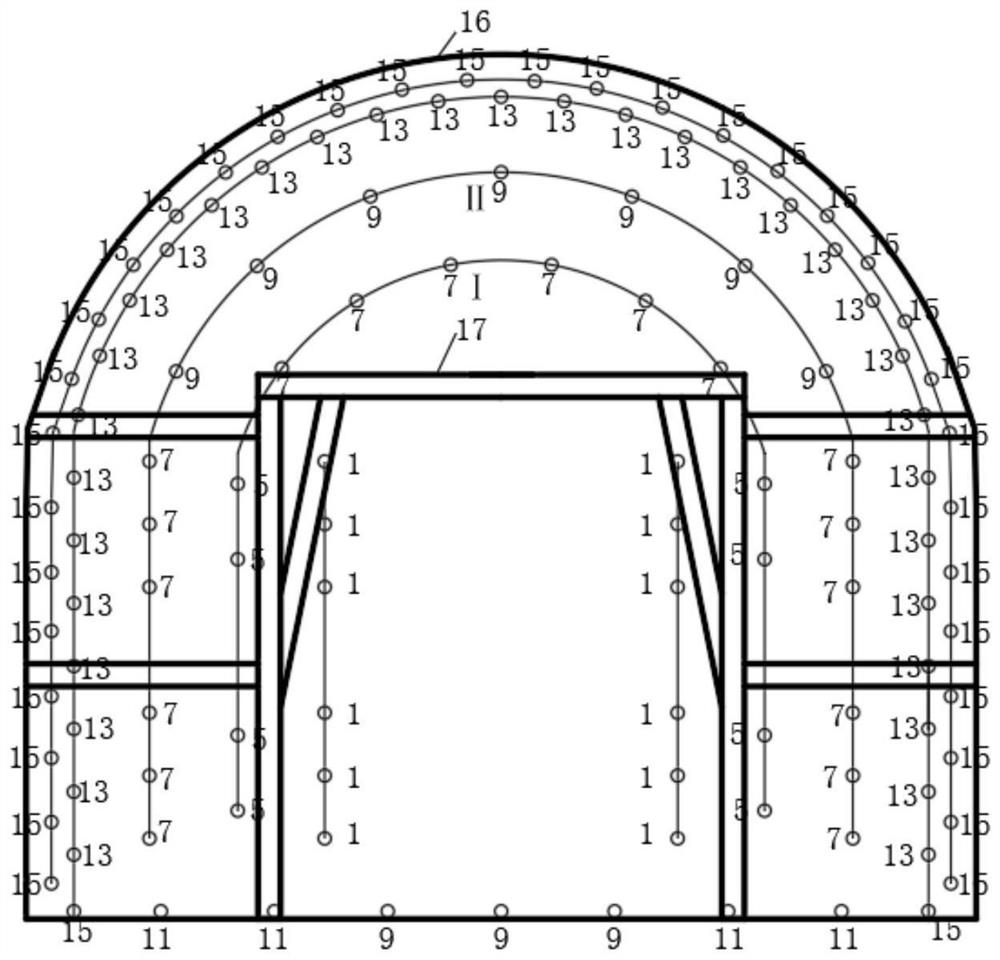

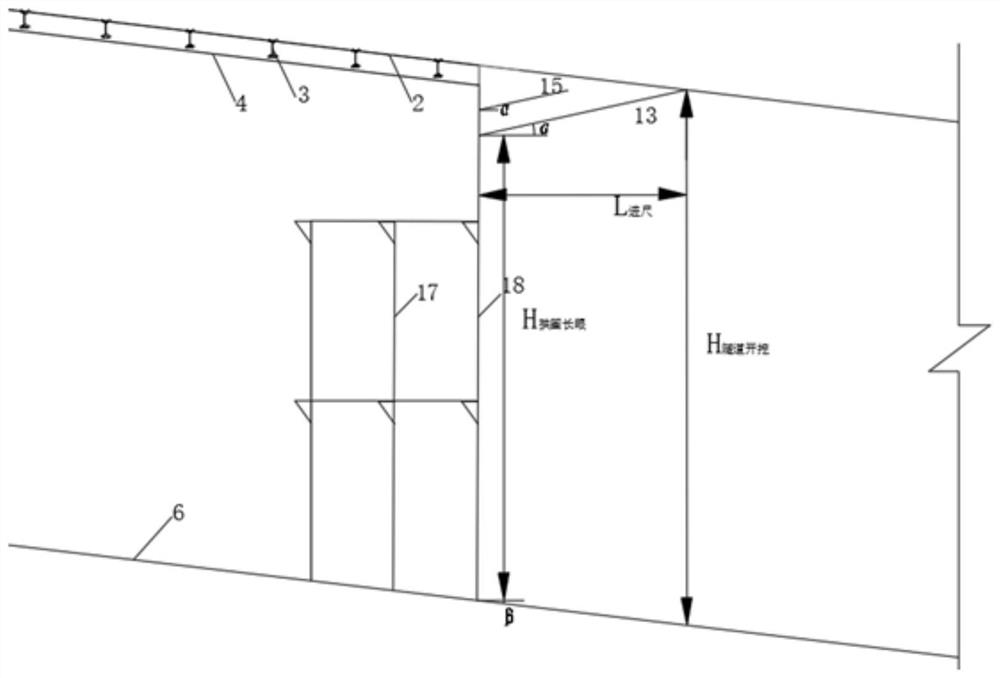

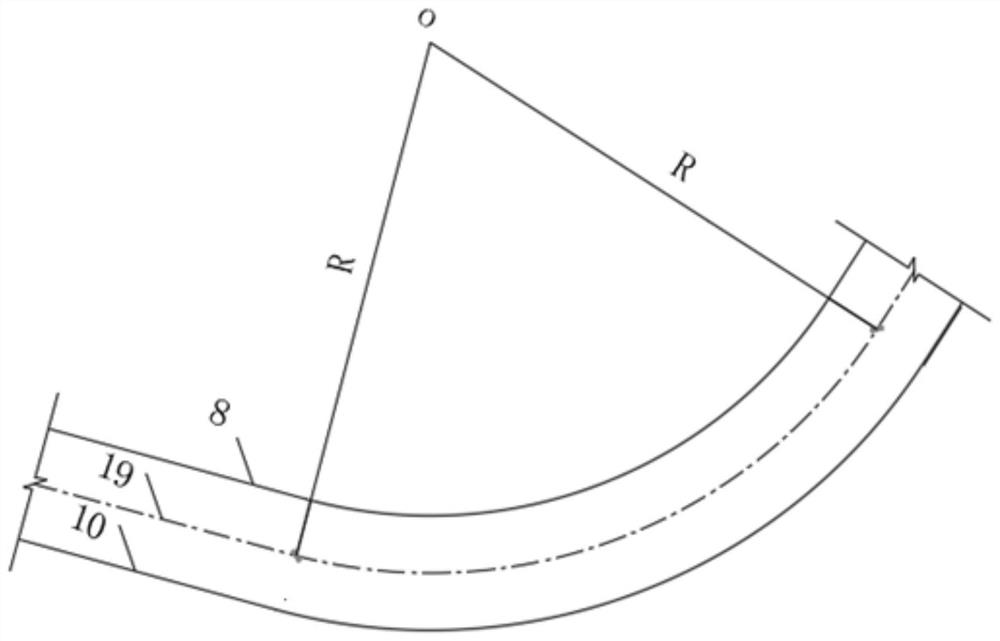

[0073] There is an existing 220KV high-voltage iron tower on the side of a tunnel in a shallow buried subway section. The design requires that the blasting vibration velocity V does not exceed 1cm / s, the design width B of tunnel excavation is 6.52m, and the design vertical height H of tunnel excavation 拱圈长眼 is 6.48m. The surrounding rock grade is grade IV, and the integrity of the rock mass is good. The maximum slope of the tunnel along the slope is 12% and the minimum slope is 11.83%. The inner contour line of the tunnel excavation side wall 8, the outer contour line of the tunnel excavation side wall 10 and the center line of the tunnel line 19 are as follows image 3 As shown, the curve radius R of the center line 19 of the tunnel line is 30m, and the footage length of a single loop tunnel is L 进尺 The vertical distance between the outer contour line 10 of the tunnel excavation side wall and the edge of the tower base is 18.15m, the height difference between the tunnel vaul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com